Synergist of light alkane and preparation method thereof

A light alkane and synergist technology, which is applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of blocking the gas outlet of the cutting nozzle, serious stratification of the synergist, and poor gas compatibility, so as to achieve cost saving, Short warm-up time and good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

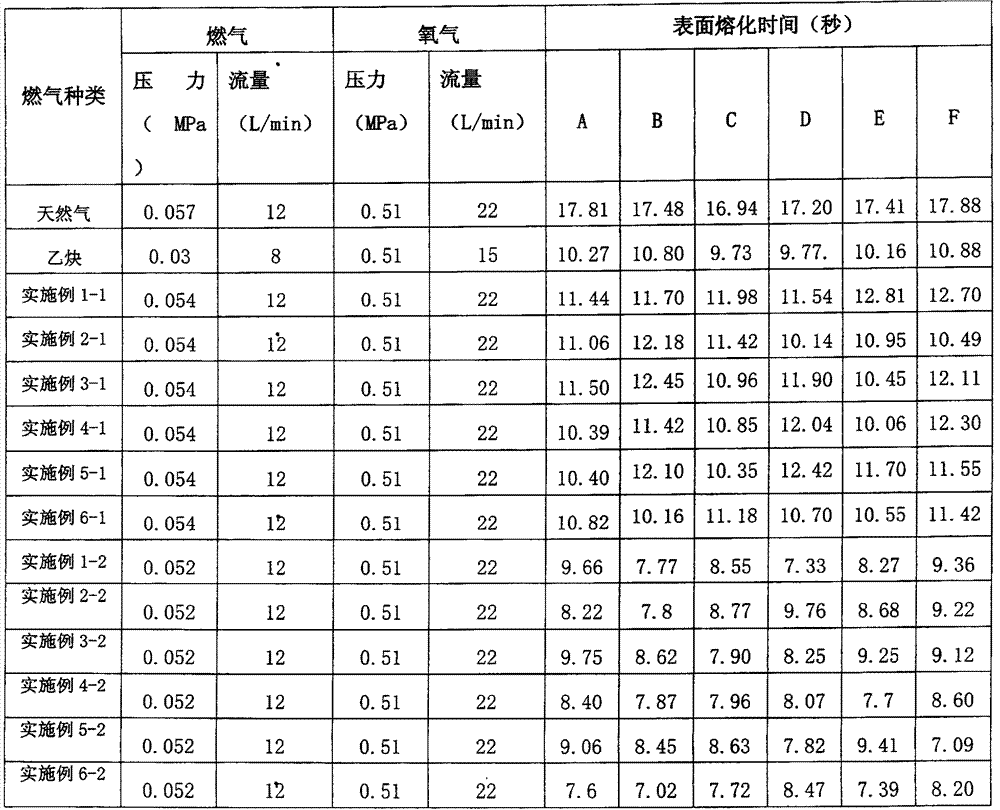

Examples

Embodiment 1

[0041] A synergist for light alkanes, consisting of the following components by weight percentage:

[0042] No. 6 aromatic-free solvent oil 29%;

[0043] MTBE 0.5%;

[0044] Di-tert-butyl peroxide 41.5%;

[0045] T-Amyl Peroxide 29%.

[0046] After weighing and measuring according to the above ratio, add the liquid into the tank in turn and stir slowly for 30 minutes. After standing for 20 minutes, pack it with packaging materials to obtain the finished product. The usage amount of the synergist is 1% of the weight of light alkanes.

Embodiment 2

[0048] A synergist for light alkanes, consisting of the following components by weight percentage:

[0049] No. 6 aromatic-free solvent oil 26%;

[0050] MTBE 1.5%;

[0051] Di-tert-butyl peroxide 42%;

[0052] T-Amyl Peroxide 30.5%.

[0053] After weighing and measuring according to the above ratio, add the liquid into the tank in turn and stir slowly for 30 minutes. After standing for 20 minutes, pack it with packaging materials to obtain the finished product. The usage amount of the synergist is 2% by weight of light alkanes.

Embodiment 3

[0055] A synergist for light alkanes, consisting of the following components by weight percentage:

[0056] No. 6 aromatic-free solvent oil 28%;

[0057] MTBE 2%;

[0058] Di-tert-butyl peroxide 37%;

[0059] T-Amyl Peroxide 33%.

[0060] After weighing and measuring according to the above ratio, add the liquid into the tank in turn and stir slowly for 30 minutes. After standing for 20 minutes, pack it with packaging materials to obtain the finished product. The usage amount of the synergist is 1% of the weight of light alkanes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com