Method for fermentation production of L-tryptophan with high efficiency

A tryptophan, high-efficiency technology, applied in the direction of biochemical equipment and methods, fermentation, bioreactor/fermenter combination, etc., can solve the problems of short fermentation cycle, high cost, low fermentation unit, etc., to reduce labor intensity, The effect of improving accuracy and prolonging the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

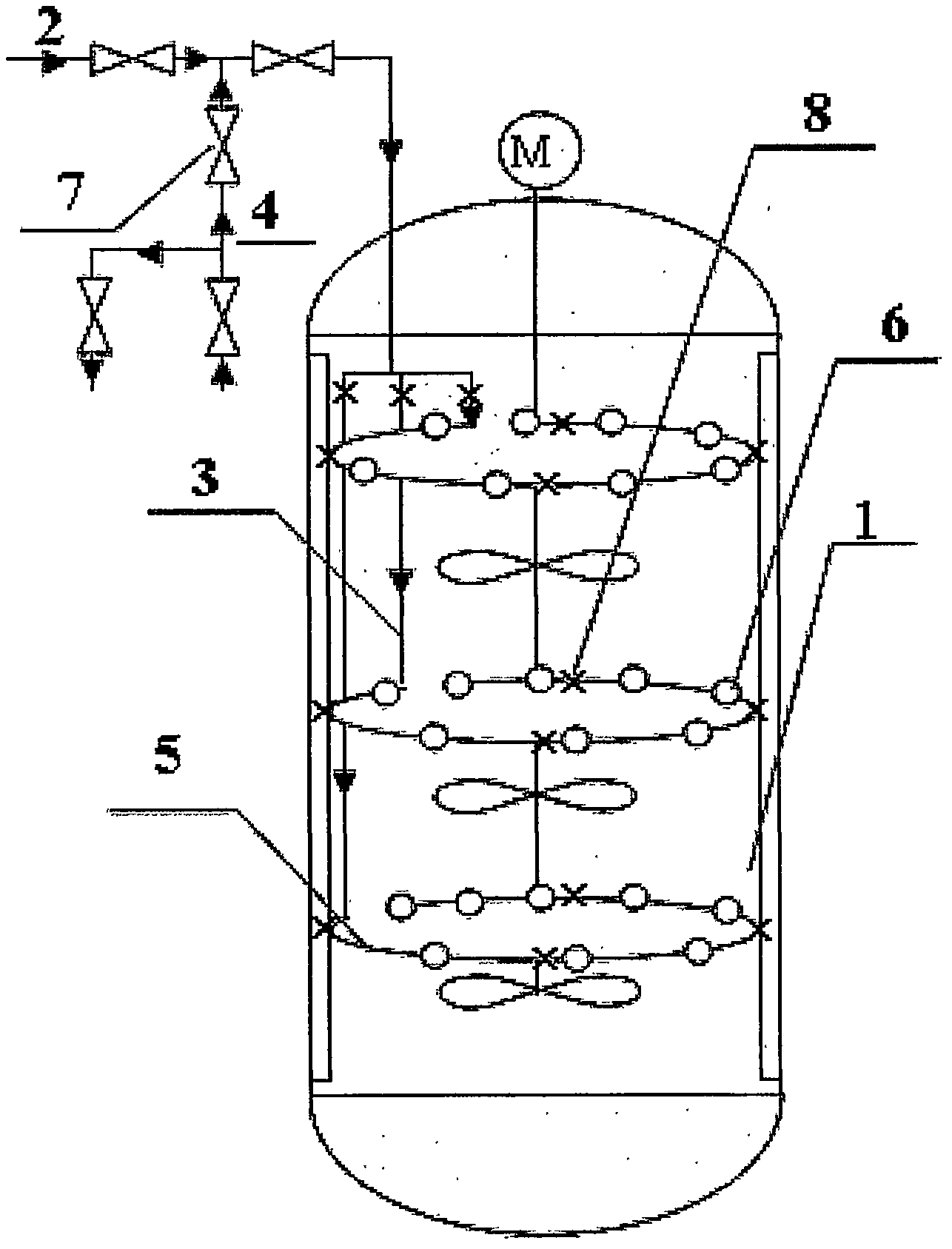

Image

Examples

Embodiment 1

[0040] Seed culture medium: glucose 5.0%, disodium hydrogen phosphate 0.2%, peptone 1.0%, magnesium chloride 0.1%, trisodium citrate 0.10%, ferrous sulfate 0.001%, manganese sulfate 0.0001%, the above are weight percentages, before sterilization NaOH adjusted the pH to 6.5.

[0041] Fermentation medium: 5.0% glucose, 0.5% disodium hydrogen phosphate, 0.5% peptone, 0.2% citric acid, 0.0009% manganese sulfate, 0.02% ferrous sulfate, the above are percentages by weight, and the pH is adjusted to 6.5, adjust the pH to 6.5 with high-concentration ammonia water after sterilization.

[0042] Insert the strains into the seed medium with an inoculum size of 0.1% v / v, and cultivate them in a 1000L seed tank under the conditions of tank temperature 33°C, pH 6.5, tank pressure 0.06MPa and dissolved oxygen above 60%. ~17h, when the absorbance value at 600nm is 10~30, inoculate 4m with 1.0% v / v 3 In the fermentation tank, the following process is used to control: tank temperature 33°C, ta...

Embodiment 2

[0045] Seed culture medium: glucose 2.0%, disodium hydrogen phosphate 0.2%, peptone 1.0%, magnesium chloride 0.1%, trisodium citrate 0.10%, ferrous sulfate 0.001%, manganese sulfate 0.0001%, the above are weight percentages, before sterilization NaOH adjusted the pH to 7.5.

[0046] Fermentation medium: 0.5% glucose, 0.5% disodium hydrogen phosphate, 0.5% peptone, 0.5% citric acid, 0.0009% manganese sulfate, 0.02% ferrous sulfate, the above are percentages by weight, and the pH is adjusted to 7.5, adjust the pH to 7.5 with high-concentration ammonia water after sterilization.

[0047] Insert the strains into the seed medium with an inoculum size of 5.0% v / v, and cultivate them in a 1000L seed tank under the conditions of tank temperature 38°C, pH 6.5, tank pressure 0.05MPa and dissolved oxygen above 60%. ~17h, when the absorbance value at 600nm is 10~30, inoculate 4m with 15% v / v 3 In the fermenter, the following process is used to control: tank temperature 28°C, tank pressu...

Embodiment 3

[0050] Seed medium: 2.5% glucose, 1.5% disodium hydrogen phosphate, 0.5% peptone, 0.5% magnesium chloride, 0.50% trisodium citrate, 0.0001% ferrous sulfate, 0.001% manganese sulfate, the above are weight percentages, before sterilization NaOH adjusted the pH to 6.8.

[0051] Fermentation medium: 5.0% glucose, 1.5% disodium hydrogen phosphate, 0.15% peptone, 0.2% citric acid, 0.00045% manganese sulfate, 0.002% ferrous sulfate, the above are percentages by weight, and the pH is adjusted to 6.8, adjust the pH to 6.8 with high-concentration ammonia water after sterilization.

[0052] Insert the strains into the seed culture medium, the inoculation amount is 3.0% v / v, and cultivate them in a 1000L seed tank under the conditions of tank temperature 30°C, pH 6.8, tank pressure 0.04MPa and dissolved oxygen above 60%. ~17h, when the absorbance value at 600nm is 10~30, inoculate 4m with 15% v / v 3 In the fermentation tank, the following process is used for control: tank temperature 30°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com