Solar cell panel, manufacturing method thereof and solar cell comprising solar cell panel

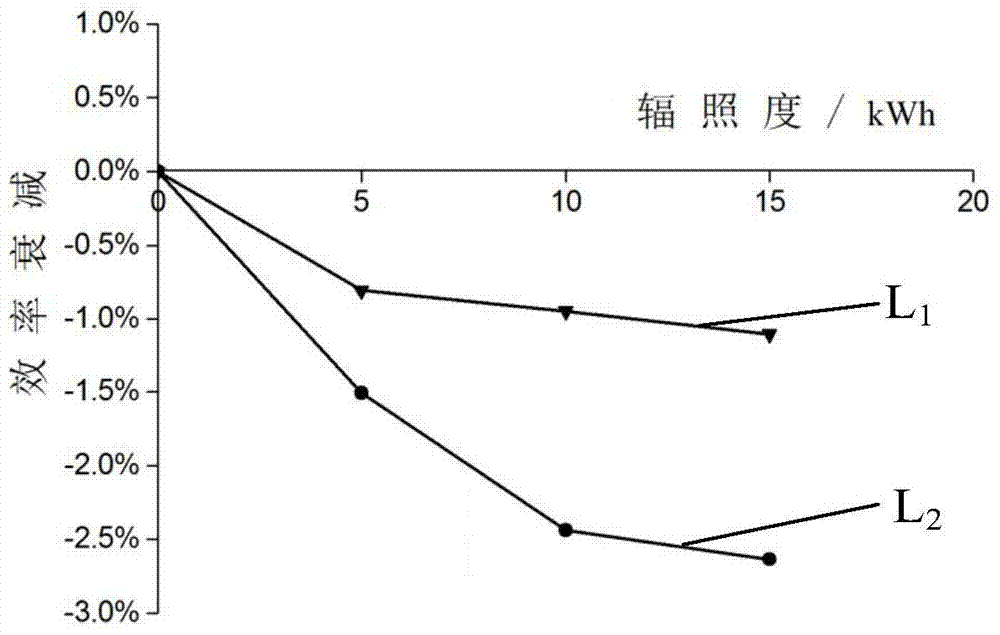

A solar cell panel and silicon nitride layer technology, applied in the field of solar cells, can solve the problems of solar cell light-induced attenuation and achieve the effects of suppressing light-induced attenuation, high photoelectric conversion efficiency, and reducing light-induced attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In addition, the present invention also provides a method for preparing a solar cell panel, which includes the step of disposing a silicon nitride film on the surface of the silicon wafer, wherein the step of disposing the silicon nitride film on the surface of the silicon wafer includes: disposing a second silicon nitride film on the silicon wafer A silicon nitride layer; a second silicon nitride layer with a higher refractive index than the first silicon nitride layer is set on the first silicon nitride layer.

[0033]In the solar panel formed by the above method, since the silicon nitride layer on the outer layer of the silicon wafer has a higher refractive index, the surface of the silicon wafer has a stronger blocking effect on ultraviolet rays, thereby effectively weakening the intensity of ultraviolet rays entering the silicon nitride film. This can prevent the incoming ultraviolet light from activating the K inside the silicon nitride film to a certain extent. 0...

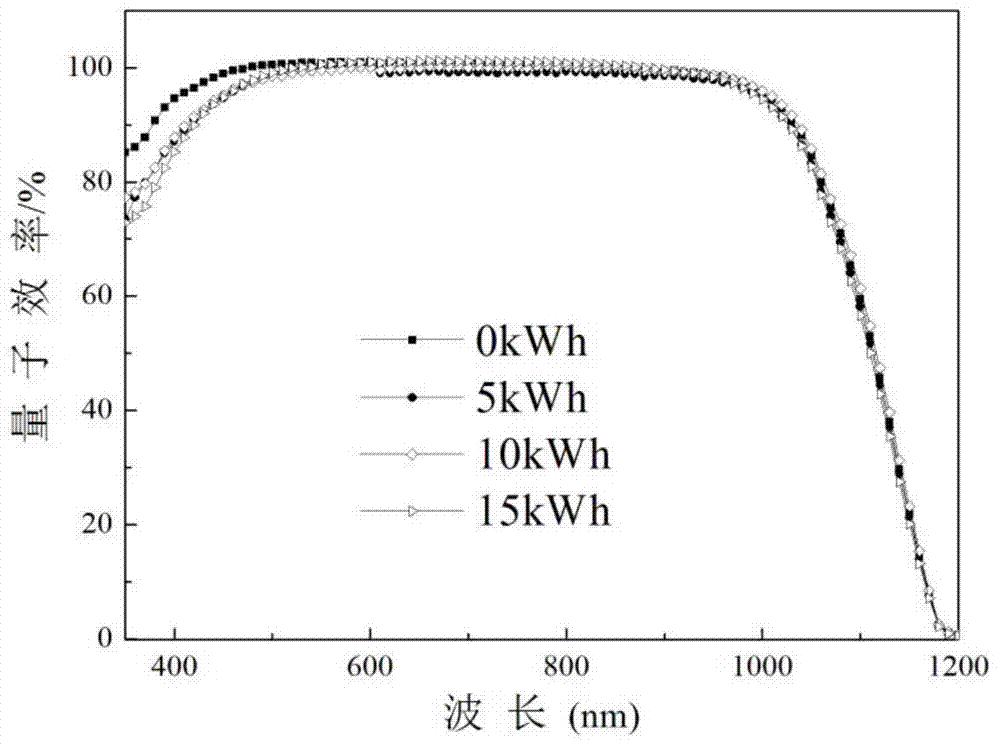

Embodiment 1

[0042] A silicon nitride film is deposited on the surface of the silicon wafer by PECVD. The specific process flow is as follows: the deposition temperature is set to 300°C, the conveyance speed of the boat is 205cm / min, and the gas flow in the six groups of intake pipes is set to the following flow:

[0043]

[0044] Through the above process flow, a silicon wafer provided with a silicon nitride film is obtained, and a solar battery panel is prepared from the silicon wafer.

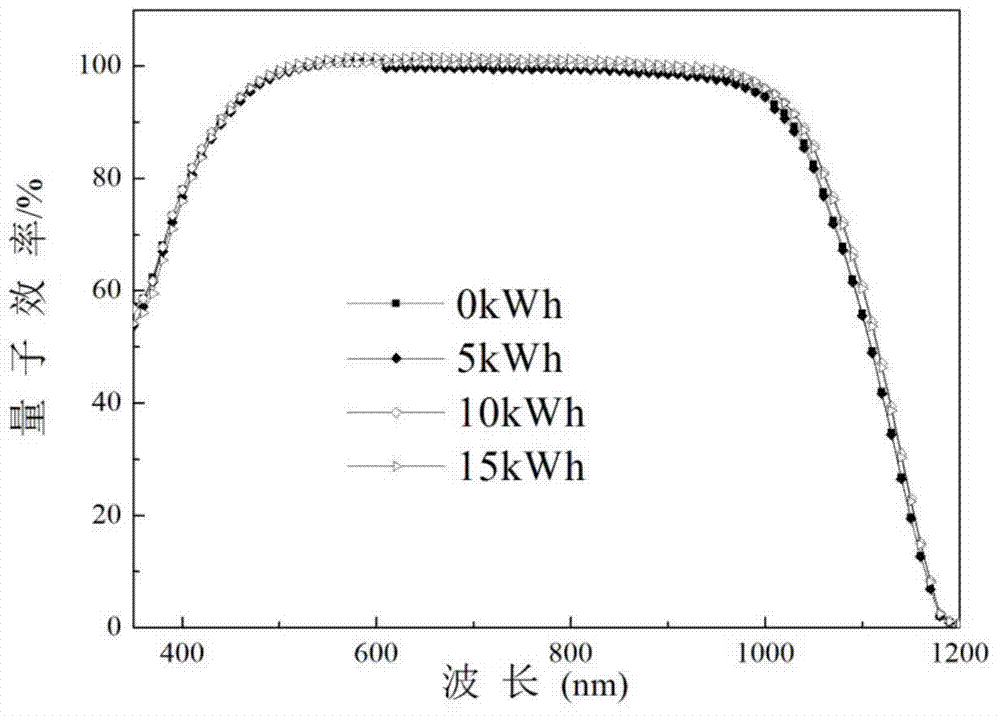

Embodiment 2

[0046] A silicon nitride film is deposited on the surface of the silicon wafer by PECVD. The specific process flow is as follows: the deposition temperature is set to 300°C, the conveyance speed of the boat is 205cm / min, and the gas flow in the six groups of intake pipes is set to the following flow:

[0047]

[0048] Through the above process flow, a silicon wafer provided with a silicon nitride film is obtained, and a solar battery panel is prepared from the silicon wafer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com