Method and equipment for producing liquid sulfur dioxide through sulfur trioxide and sulphur

A liquid sulfur dioxide and sulfur trioxide technology, which is applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of high investment cost, increase of air separation units, and high operation cost, and achieves reduction of production and operation cost, technological progress, etc. Simple process, stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

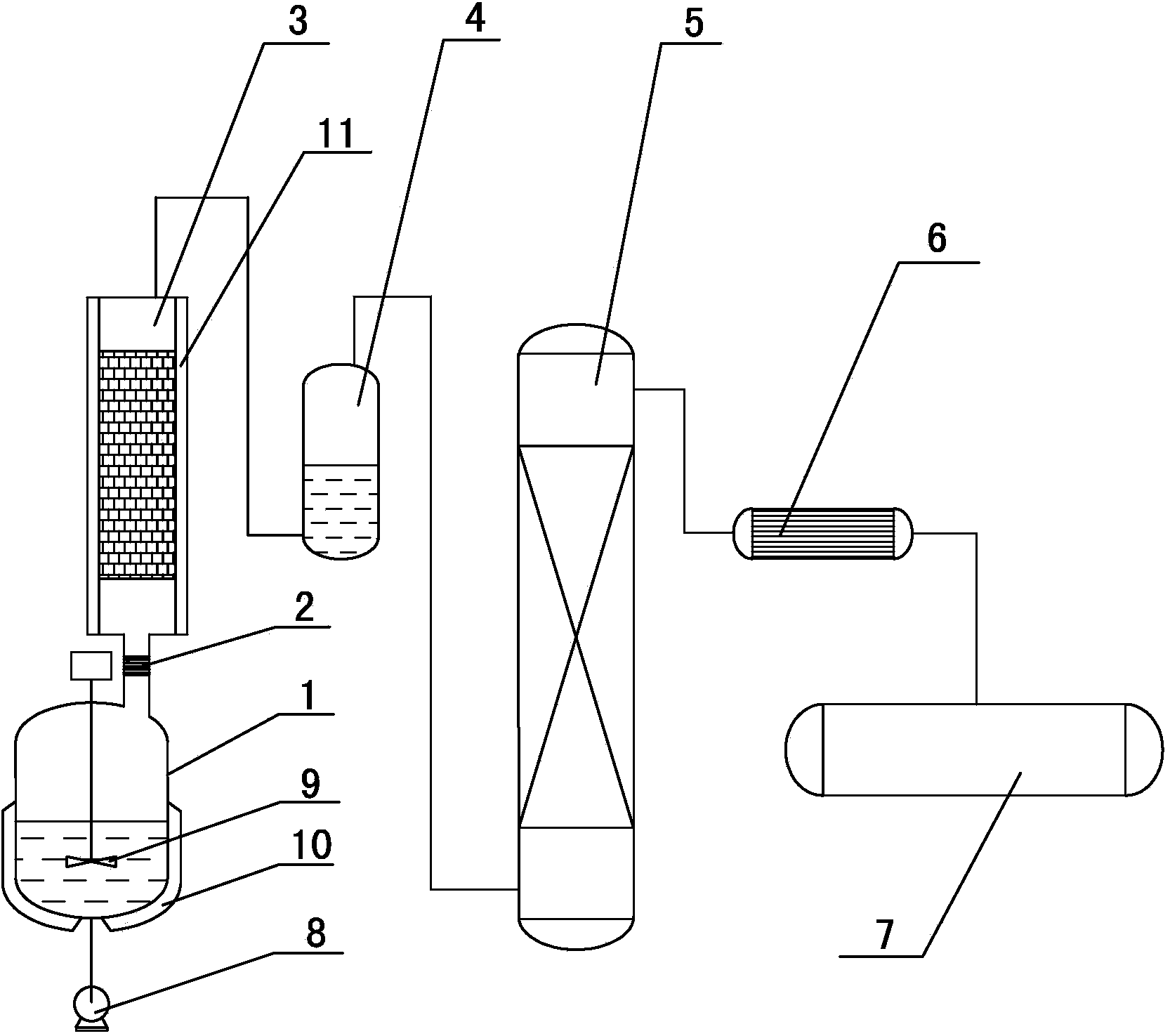

[0037] (1) Pass 80% concentrated sulfuric acid into the reactor, the addition amount is 30% of the volume of the reactor, the temperature of the reactor is raised to 80°C, and then the liquid sulfur trioxide at 30°C and the liquid sulfur at 140°C are in accordance with the mass flow ratio of 4:1, Pass it into the reaction kettle, stir and react, the liquid sulfur trioxide and liquid sulfur will immediately generate gaseous sulfur dioxide under the mixing action of concentrated sulfuric acid, and release a lot of heat, and control the temperature of the reaction kettle to maintain 80 °C under the action of jacketed circulating water;

[0038] (2) The sulfur dioxide gas mixed with sulfur trioxide enters the packed reaction tower through the demister and continues to react. The sulfur trioxide contacts with solid sulfur and is further converted into sulfur dioxide, and the temperature of the packed reaction tower is kept at 60°C under the action of cooling water ;

[0039] (3) Th...

Embodiment 2

[0041] (1) Pass 98% concentrated sulfuric acid into the reactor, the addition amount is 40% of the volume of the reactor, the temperature of the reactor is raised to 90°C, and then the liquid sulfur trioxide at 35°C and the liquid sulfur at 130°C are in accordance with the mass flow ratio of 5:1, Pass it into the reaction kettle, stir and react, the liquid sulfur trioxide and liquid sulfur will immediately generate gaseous sulfur dioxide under the mixing action of concentrated sulfuric acid, and release a lot of heat, and the temperature of the reaction kettle is controlled to maintain 95 °C under the action of jacketed circulating water;

[0042] (2) The sulfur dioxide gas mixed with sulfur trioxide enters the packed reaction tower through the demister and continues to react. The sulfur trioxide contacts with solid sulfur and is further converted into sulfur dioxide, and the temperature of the packed reaction tower is kept at 80°C under the action of cooling water ;

[0043] ...

Embodiment 3

[0045] (1) Pass 20% oleum into the reactor, the amount added is 50% of the volume of the reactor, the temperature of the reactor is raised to 100°C, and then liquid sulfur trioxide at 40°C and liquid sulfur at 135°C are in accordance with the mass flow ratio of 5: 1. Pass it into the reaction kettle, stir and react, the liquid sulfur trioxide and liquid sulfur will immediately generate gaseous sulfur dioxide under the mixing action of oleum, and release a lot of heat, and control the temperature of the reaction kettle to maintain 105°C under the action of jacketed circulating water ;

[0046] (2) The sulfur dioxide gas mixed with sulfur trioxide enters the packed reaction tower through the demister, and the unreacted sulfur trioxide is contacted with solid sulfur to be further converted into sulfur dioxide, and the temperature of the packed reaction tower is kept at 90°C;

[0047] (3) The sulfur dioxide gas from the packed reaction tower enters the purification tower and pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com