Rigid polyurethane foam and raw material composition, combined polyether, preparation method and application

A technology of rigid polyurethane and raw material composition, applied in the field of polyurethane materials, can solve the problems of environmental damage, high viscosity of all-water foaming system, poor dimensional stability, etc., and achieve the effects of safe production operation, zero ODP value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of combined polyether:

[0039] 4 parts of polyether polyol SA380, 6 parts of polyether polyol DL-1000D, 0.2 parts of silicone foam stabilizer L-6900, 0.1 part of N,N-dimethylbenzylamine, 0.03 parts of 1,2,3, 5-tris(dimethylaminopropyl)-hexahydrotriazine and 0.37 parts deionized water.

[0040] According to the above formula, add each ingredient into a stainless steel mixing kettle, stir at a speed of 500 rpm at room temperature for 1 hour, and then discharge the ingredients.

[0041] (2) Preparation of rigid polyurethane foam:

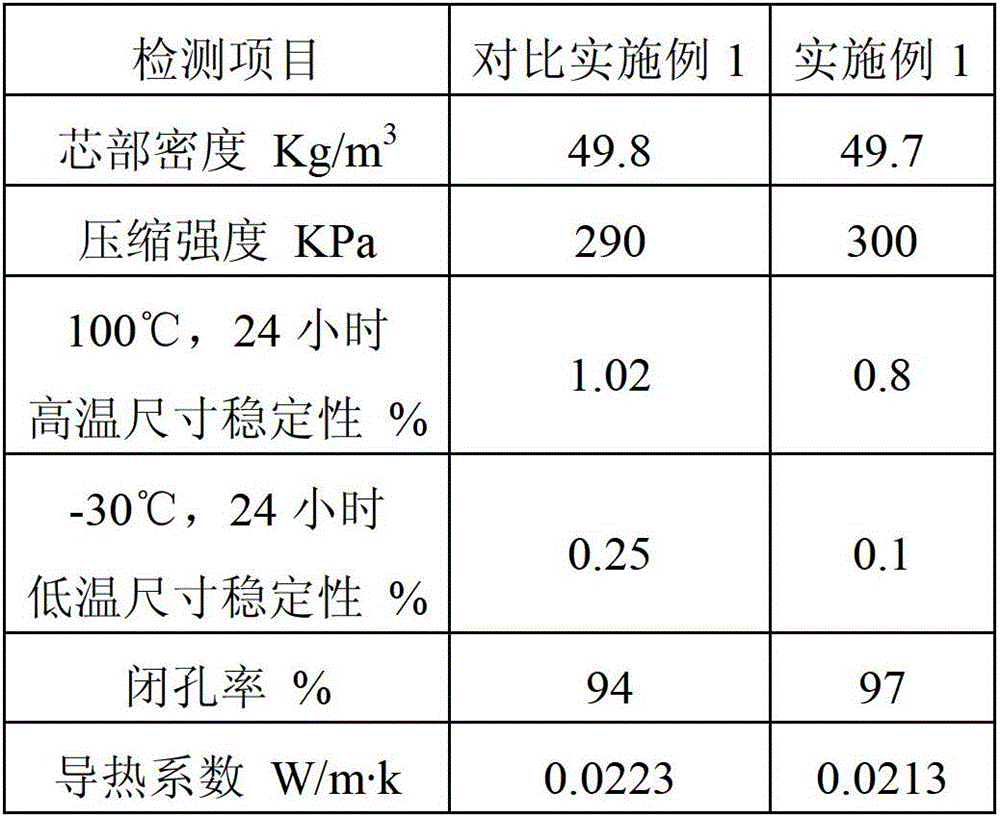

[0042] Mix the combined polyether and isocyanate PM-200 of Example 1 at 20°C according to the mass ratio of 1:1.6, use a high-pressure foaming machine to foam, and inject it into a mold to obtain a core density of 50Kg / m 3 The rigid polyurethane foam used for pipe insulation is shown in Table 1 for the physical properties of the rigid polyurethane foam.

Embodiment 2

[0052] (1) Preparation of combined polyether:

[0053] 6 parts of polyether polyol SA380, 4 parts of polyether polyol DL-1000D, 0.2 parts of silicone foam stabilizer L-6900, 0.1 part of N,N-dimethylbenzylamine, 0.04 parts of 1,2,3, 5-tris(dimethylaminopropyl)-hexahydrotriazine and 0.33 parts deionized water.

[0054] According to the above formula, add each ingredient into a stainless steel mixing kettle, stir at a speed of 500 rpm at room temperature for 1 hour, and then discharge the ingredients.

[0055] (2) Preparation of rigid polyurethane foam:

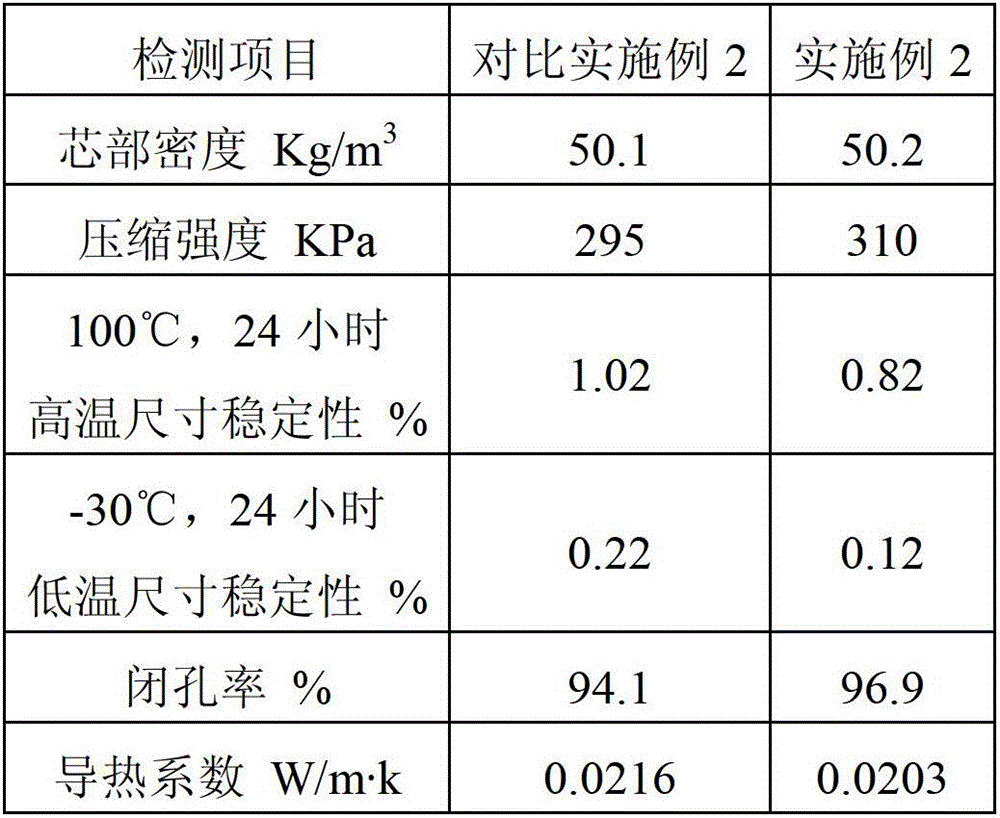

[0056] Mix the combined polyether and isocyanate PM-200 in Example 2 at 20°C according to the mass ratio of 1:1.6, use a high-pressure foaming machine to foam, and inject it into the mold to obtain a core density of 50Kg / m 3 The rigid polyurethane foam used for pipe insulation is shown in Table 2 for the physical properties of the rigid polyurethane foam.

Embodiment 3

[0066] (1) Preparation of combined polyether:

[0067] 5 parts of polyether polyol SA380, 5 parts of polyether polyol DL-1000D, 0.2 parts of silicone foam stabilizer L-6900, 0.13 parts of N,N-dimethylbenzylamine, 0.04 parts of 1,2,3, 5-tris(dimethylaminopropyl)-hexahydrotriazine and 0.36 parts deionized water.

[0068] According to the above formula, add each ingredient into a stainless steel mixing kettle, stir at a speed of 500 rpm at room temperature for 1 hour, and then discharge the ingredients.

[0069] (2) Preparation of rigid polyurethane foam:

[0070] Mix the combined polyether of Example 3 and isocyanate PM-200 at 20°C according to the mass ratio of 1:1.6, use a high-pressure foaming machine to foam, and inject it into a mold to obtain a core density of 50Kg / m 3 The rigid polyurethane foam used for pipe insulation, the physical properties of the rigid polyurethane foam are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com