Airlift type magnetic anion bioreactor

A bioreactor and negative ion technology, applied in the field of biochemical cultivation in life science laboratories, can solve the problems of liquid culture efficiency reduction, unfavorable, bacterial species or cell decline, etc., to improve cell growth vigor and growth, increase production time and Yield, effect of promoting metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

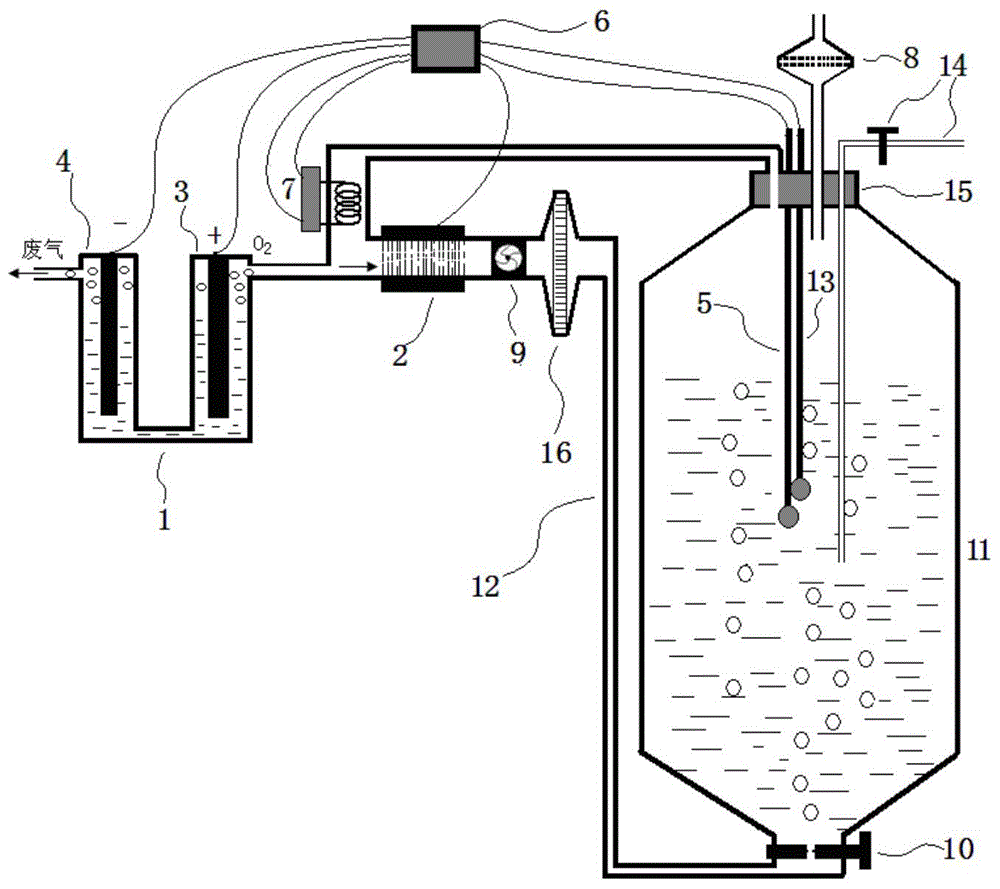

[0021] Such as figure 1 As shown, an airlift type magnetic negative ion bioreactor includes an electrolytic oxygen tank 1, a magnetic field-high voltage generator 2 arranged on the oxygen path on the electrolytic oxygen tank 1, an electrolytic positive electrode 3 and an electrolytic negative electrode 4 , oxygen electrode 5 and power controller 6, liquid culture tank 11 and its bottom valve 10, air circulation channel 12 and its internal temperature controller 7, feed pipe 8 and air pump 9, pH meter and thermometer connected with the controller 13. The sampling port and its valve 14, the tank top cover 15, and the air filter 16 on the air circulation channel 12.

[0022] The electrolysis positive electrode 3 of the electrolysis oxygen water tank 1 releases oxygen into the magnetic field-high voltage generator 2 through the electrolysis of water, and the magnetic field located on the air circulation channel 12-the high voltage electrodes of the high voltage generator 2 go deep...

Embodiment 2

[0026] Example 2: Application example in aerobic cell culture.

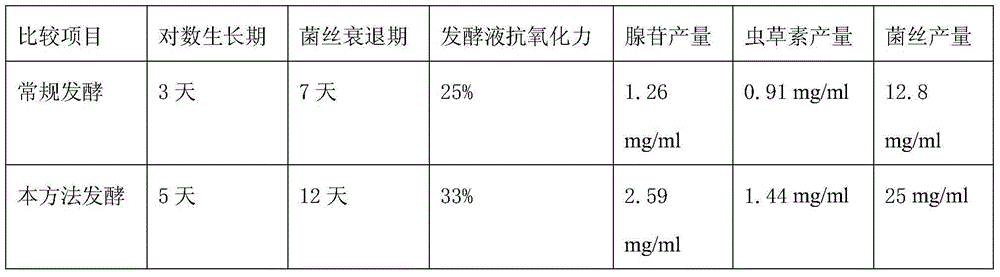

[0027] Take the fermentation of Cordyceps militaris mycelium as an example:

[0028] Step 1. First, set the temperature controller according to the suitable temperature for the growth of the Cordyceps militaris strain. The temperature range in the liquid culture tank 11 is controlled at 15-16 degrees Celsius. The aseptic operation injects the sterile medium into the tank. The components of the sterile culture medium include deionized water, yeast extract, glucose, potassium dihydrogen phosphate and zinc sulfate, and the mass ratio is: 1500(g):5(g): 50(g):0.3(g):0.3(g), inoculated with Cordyceps militatirs under aseptic conditions.

[0029] Step 2, turn on the air pump 9, the gas in the air circulation channel 12 starts to circulate, stir the fermentation liquid in the liquid culture tank 11, and set the dissolved oxygen rate range of 16-18mg / L and pH value range for the power controller 6 At 6.0-7.5.

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com