Preparation method for camellia seed polypeptide

A technology of camellia oleifera seeds and camellia oleifera seed meal, which is applied in the field of preparation of camellia oleifera seed polypeptides, and achieves the effects of improving utilization rate, good extraction effect and mild extraction process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

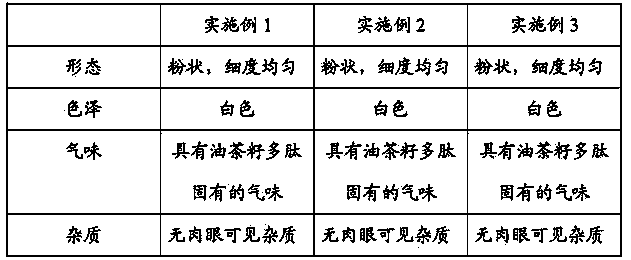

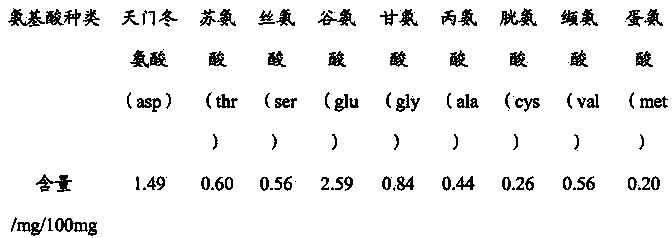

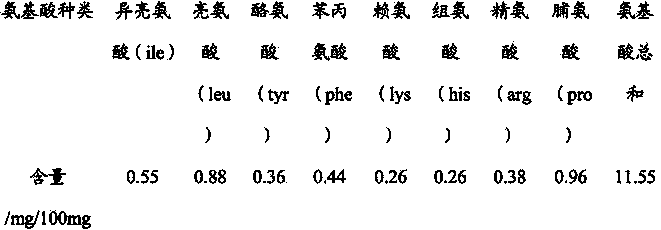

Examples

Embodiment 1

[0024] A preparation method of Camellia oleifera polypeptide, the preparation method is specifically as follows:

[0025] (1) Enzymolysis: Mix the pulverized camellia seed meal powder with 80 mesh sieve with water according to the ratio of material to liquid 1:6, adjust the pH value to 7.25, add 0.04% compound plant hydrolytic enzyme of camellia seed meal powder, Enzyme hydrolyze at 65°C for 3.5h, inactivate the enzyme at 85°C for 10min after enzymolysis, and then centrifuge at 3000rpm for 15min to obtain the residue of Camellia oleifera seed meal;

[0026] (2) Ultrasonic-assisted alkaline extraction: mix the Camellia oleifera seed meal residue (on a dry basis) obtained in step (1) with water at a mass ratio of 1:25, adjust the pH value to 10.0, and conduct alkaline extraction at 40°C for 90 minutes. Ultrasound is used to assist in the extraction process. The power of the ultrasonic wave is 300W, and the ultrasonic time is 20min.

[0027] (3) Acid precipitation: adjust the pH...

Embodiment 2

[0030] A preparation method of Camellia oleifera polypeptide, the preparation method is specifically as follows:

[0031] (1) Enzymolysis: Mix the pulverized Camellia oleifera seed powder through a 100-mesh sieve with water at a material-to-liquid ratio of 1:7, adjust the pH value to 7.30, add 0.05% compound plant hydrolytic enzyme of Camellia oleifera seed powder, Enzymolysis at 70°C for 3 hours, after enzymolysis, inactivate the enzyme at 85°C for 15 minutes, then centrifuge at 3200rpm for 10 minutes to obtain the residue of Camellia oleifera seed meal;

[0032] (2) Ultrasonic-assisted alkaline extraction: mix the Camellia oleifera seed meal residue (on a dry basis) obtained in step (1) with water at a mass ratio of 1:25, adjust the pH value to 10.5, and carry out alkaline extraction at 45°C for 80 minutes. The extraction process is assisted by ultrasonic waves, the power of the ultrasonic wave is 1000W, and the ultrasonic time is 20min. After the alkali extraction is comple...

Embodiment 3

[0036] A preparation method of Camellia oleifera polypeptide, the preparation method is specifically as follows:

[0037] (1) Enzymolysis: Mix the pulverized camellia seed meal powder with 100-mesh sieve with water at a material-to-liquid ratio of 1:6, adjust the pH value to 7.28, add compound plant hydrolytic enzymes with 0.048% of the camellia seed meal powder mass, Enzymolyze at 68°C for 3.25h, inactivate the enzyme at 90°C for 5min after enzymolysis, and then centrifuge at 3000rpm for 20min to obtain the residue of Camellia oleifera seed meal;

[0038] (2) Ultrasonic-assisted alkaline extraction: mix the Camellia oleifera seed meal residue (on a dry basis) obtained in step (1) with water at a mass ratio of 1:25, adjust the pH value to 10.0, and carry out alkaline extraction at 40°C for 80 minutes. Ultrasound is used to assist in the extraction process, the power of the ultrasonic wave is 800W, and the ultrasonic time is 20min. After the alkali extraction is completed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com