Method for preparing indium/tellurium porous nanowire array

A porous nanowire and nanowire technology, applied in the field of porous materials and nanomaterial preparation, can solve the problem of not combining porous nanowires, and achieve the effects of composition and structure regulation, simple preparation, and easy composition and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

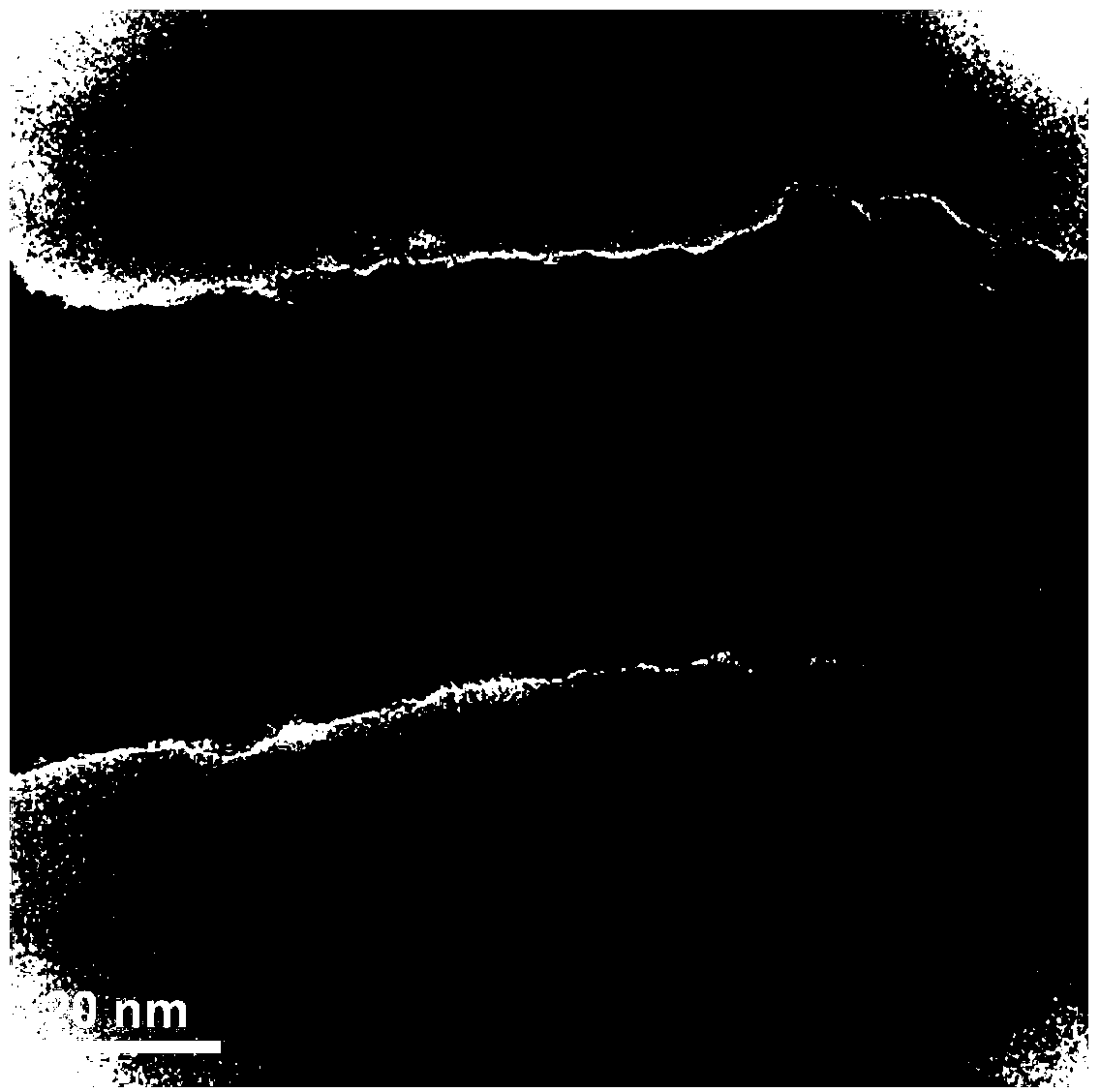

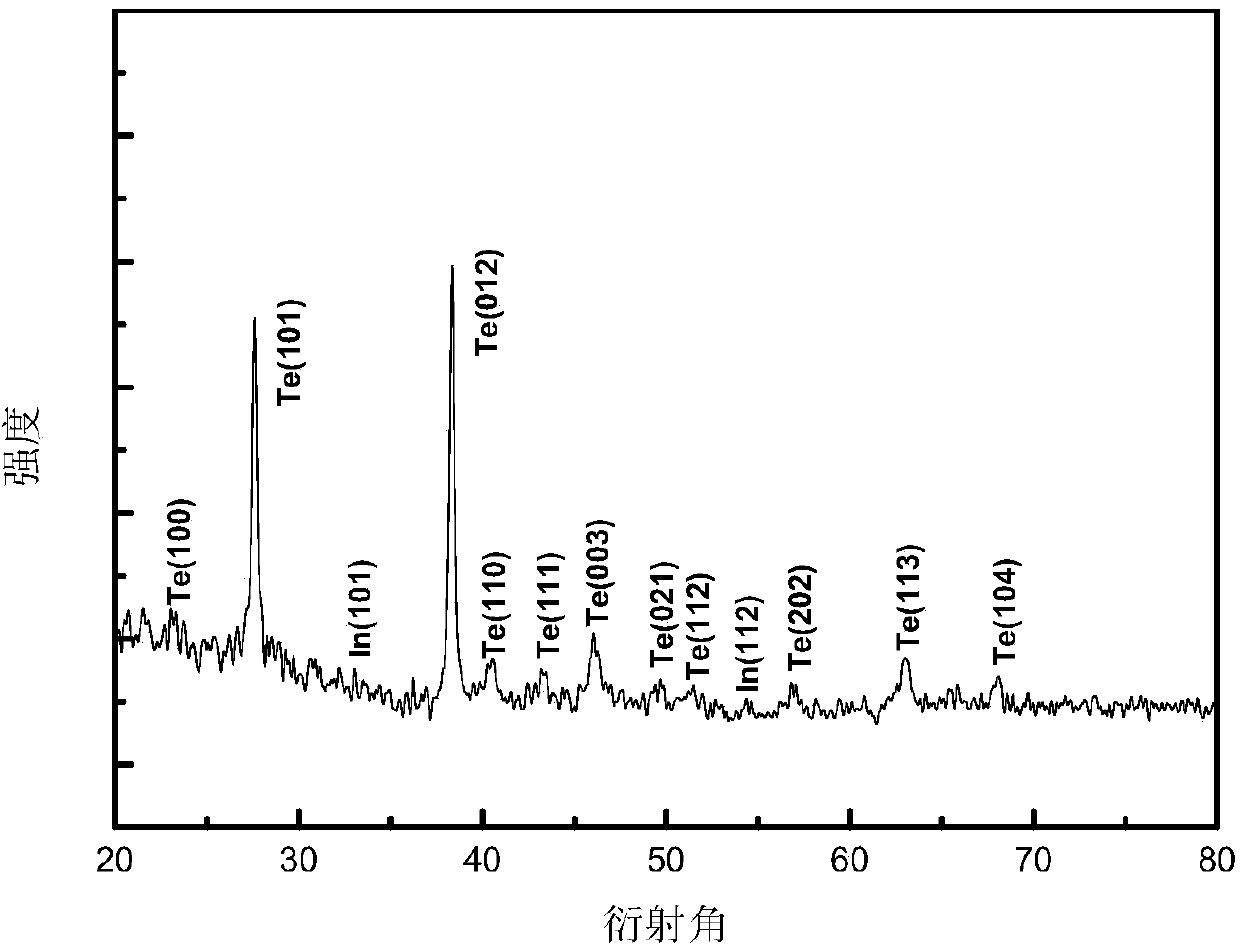

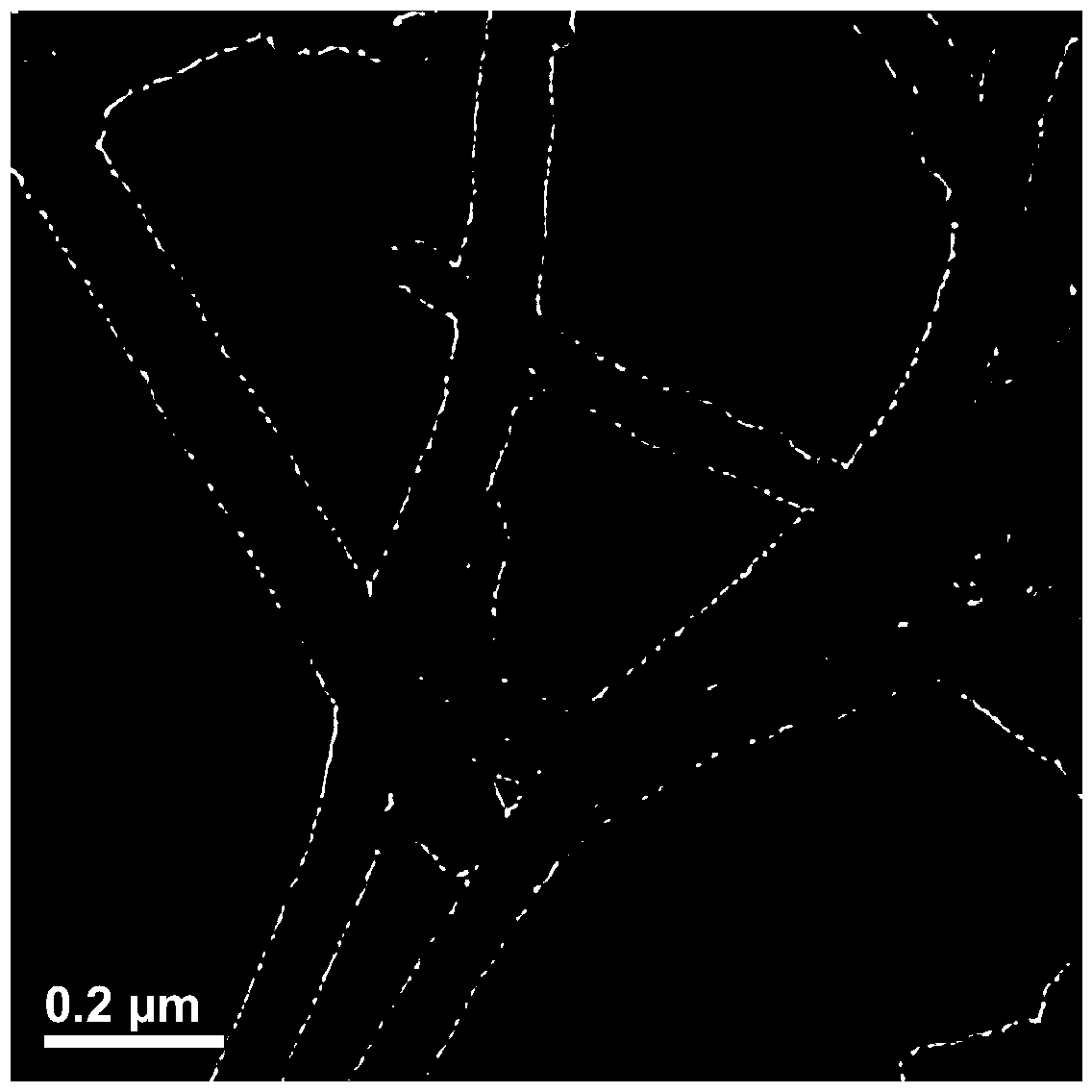

[0021] The PAA template was prepared by a secondary anodization method, and a gold film with a thickness of 100 nm to 200 nm was deposited on its backside and on the backside by sputtering evaporation as an electrode. An electrodeposition solution was then prepared, which consisted of TeO 2 , InCl 3 ·4H 2 O, tartaric acid, HNO 3 solution composition. 5mM TeO 2 Dissolved in a small amount of deionized water, at a constant temperature of 60 ℃, under the condition of magnetic stirring, add concentrated HNO dropwise with a dropper 3 After the solution became clear, the resulting solution was poured into a solution containing 2.5 mM InCl 3 ·4H 2 In the solution of O and 0.133M tartaric acid, the required electrolyte is obtained, and the pH value of the obtained electrolyte is 1. Using the pulsed electrochemical deposition method, the gold-sprayed PAA template was used as the anode, and the graphite was used as the cathode. The power was turned on, and the deposition potentia...

Embodiment 2

[0026] The PAA template was prepared by a secondary anodization method, and a gold film with a thickness of 100 nm to 200 nm was deposited on its backside and on the backside by sputtering evaporation as an electrode. An electrodeposition solution was then prepared, which consisted of TeO 2 , InCl 3 ·4H 2 O, citric acid, HNO 3 solution composition. 5mM TeO 2 Dissolved in a small amount of deionized water, at a constant temperature of 60 ℃, under the condition of magnetic stirring, add concentrated HNO dropwise with a dropper 3 After the solution became clear, the resulting solution was poured into a solution containing 2.5 mM InCl 3 ·4H2 In the solution of O and 0.133M citric acid, the required electrolyte is obtained, and the pH value of the obtained electrolyte is 1. Using the pulsed electrochemical deposition method, the gold-sprayed PAA template was used as the anode, and the graphite was used as the cathode. The power was turned on, and the deposition potential was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com