A kind of post-treatment method of silver-plated fiber and its multi-layer composite fabric and fabric

A multi-layer composite and silver-plated fiber technology, which is applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve the problem that the silver-plated fiber layer cannot be covered between the inner layer and the outer layer, and reduce the silver-plated layer and nylon fiber. Combined with issues such as firmness and affecting the service life of silver-plated fiber fabrics, it can achieve the effects of ensuring electromagnetic shielding effect, improving electromagnetic shielding effect, and protecting electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

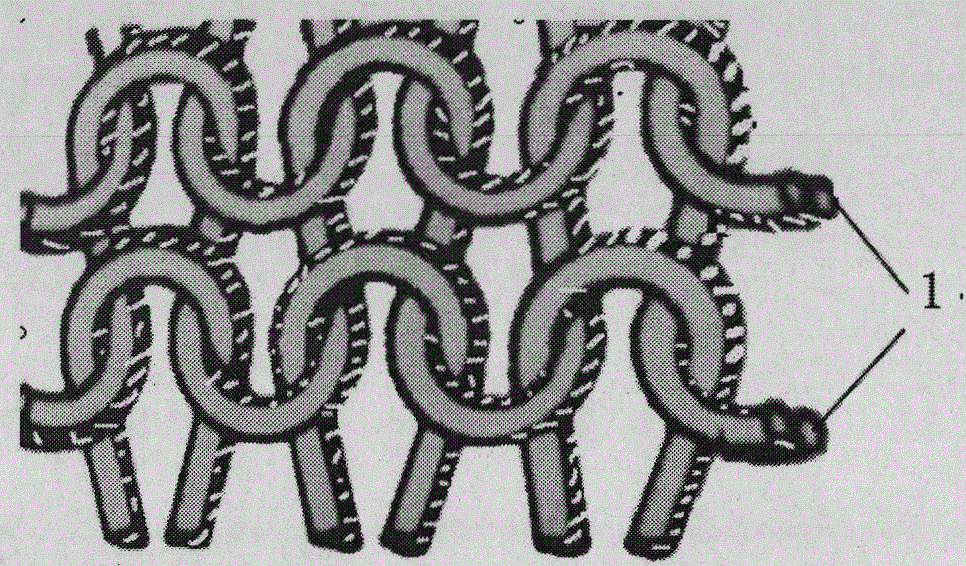

[0038] Such as figure 1 As shown, in the structure diagram of traditional silver fiber cushion sand, it includes silver fiber and nylon fiber 1.

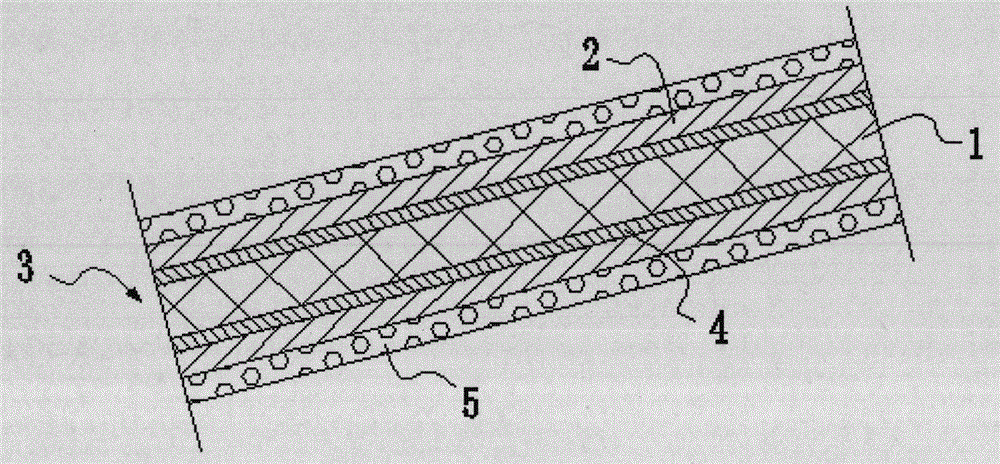

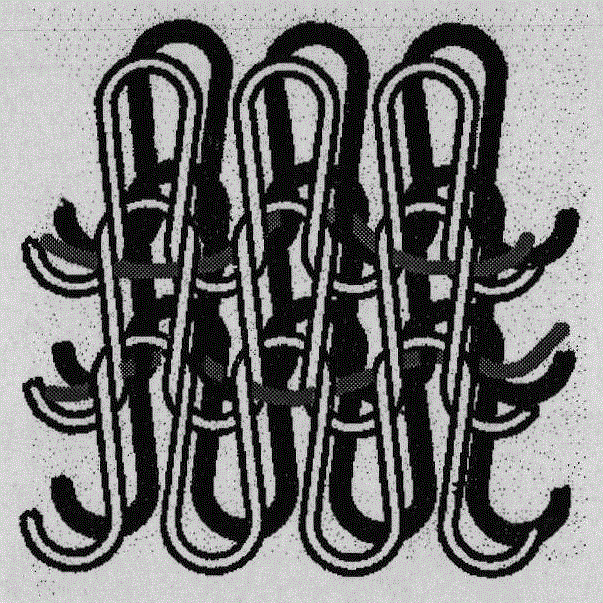

[0039] Such as figure 2 , 3 , shown in 4, a kind of silver-plated fiber, comprises the silver fiber body 3 that is made up of the silver layer 2 that is coated on the nylon fiber 1 surface layer by nylon fiber 1, forms bonding layer 4 between silver layer 2 and nylon fiber 1 , the surface of the silver layer 2 is coated with a protective layer 5 to prevent the silver layer 2 from being scratched during the weaving process. The protective layer 5 can be one or more of organic silicon liquid wax or organic fluorine liquid wax, or one or more of solvent-based polymer coating agents, or one or more of solvent-based inorganic coating agents. One or several kinds, or one or several kinds of solvent-based nano-coating agents. Among them, organic silicon liquid wax, organic fluorine liquid wax, solvent-based polymer coating agent, solv...

Embodiment 2

[0051] Such as figure 2 , 3 , shown in 4, a kind of silver-plated fiber, comprises the silver fiber body 3 that is made up of the silver layer 2 that is coated on the nylon fiber 1 surface layer by nylon fiber 1, forms bonding layer 4 between silver layer 2 and nylon fiber 1 , the surface of the silver layer 2 is coated with a protective layer 5 to prevent the silver layer 2 from being scratched during the weaving process. The protective layer 5 can be one or more of organic silicon liquid wax or organic fluorine liquid wax, or one or more of solvent-based polymer coating agents, or one or more of solvent-based inorganic coating agents. One or several kinds, or one or several kinds of solvent-based nano-coating agents. Among them, organic silicon liquid wax, organic fluorine liquid wax, solvent-based polymer coating agent, solvent-based inorganic coating agent and solvent-based nano-coating agent are all commonly used products on the market. The thickness of the protective...

Embodiment 3

[0063] Such as figure 2 , 3 , shown in 4, a kind of silver-plated fiber, comprises the silver fiber body 3 that is made up of the silver layer 2 that is coated on the nylon fiber 1 surface layer by nylon fiber 1, forms bonding layer 4 between silver layer 2 and nylon fiber 1 , the surface of the silver layer 2 is coated with a protective layer 5 to prevent the silver layer 2 from being scratched during the weaving process. The protective layer 5 can be one or more of organic silicon liquid wax or organic fluorine liquid wax, or one or more of solvent-based polymer coating agents, or one or more of solvent-based inorganic coating agents. One or several kinds, or one or several kinds of solvent-based nano-coating agents. Among them, organic silicon liquid wax, organic fluorine liquid wax, solvent-based polymer coating agent, solvent-based inorganic coating agent and solvent-based nano-coating agent are all commonly used products on the market. The thickness of the protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com