Laser device plant light and manufacturing method thereof

A laser and lighting technology, applied in the fields of botanical equipment and methods, lighting and heating equipment, horticultural methods, etc., can solve the problems of high technical difficulty in the processing process, unsuitable for mass production, and difficult to meet the lighting requirements, and achieve the response time. The effect of short, high reliability, strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

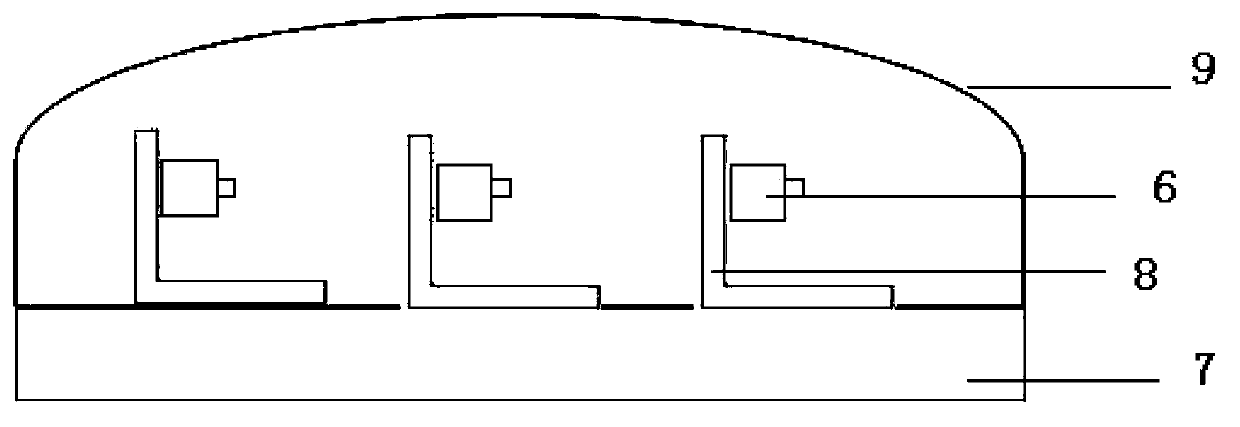

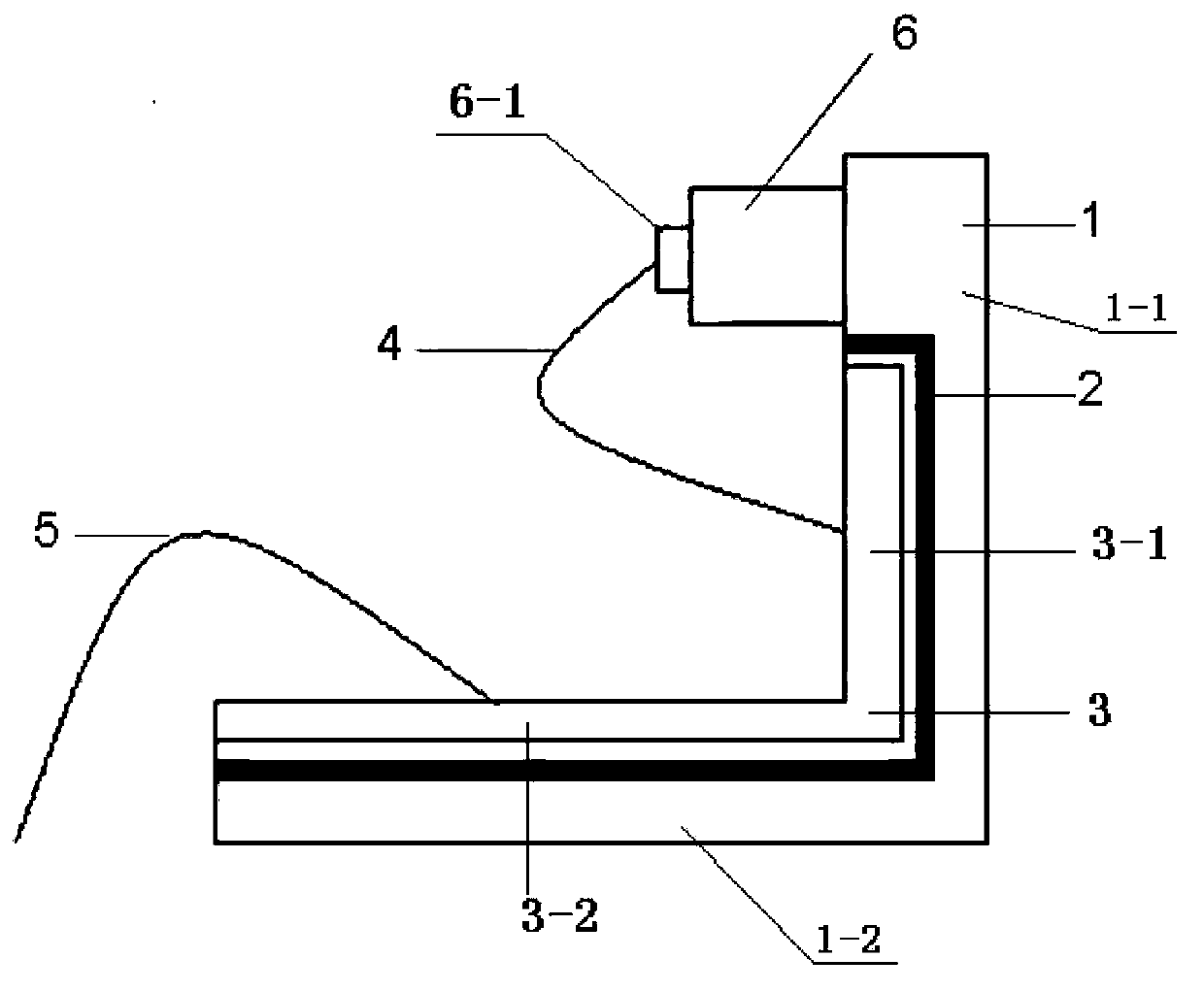

[0034] A laser plant lighting lamp, comprising a circuit board 7, a semiconductor laser die is packaged on the circuit board 7, and a dodging sheet 9 adapted to the shape of the circuit board 7 is covered above the semiconductor laser die The semiconductor laser tube core is an edge-emitting laser 6, and the semiconductor laser is electrically connected to the circuit board 7 through an L-shaped heat sink 8, and the L-shaped heat sink 8 includes an L-shaped negative electrode layer 1 , an L-shaped insulating layer 2 and an L-shaped positive electrode layer 3, an L-shaped groove is arranged on the inner surface of the L-shaped negative electrode layer 1, and the L-shaped positive electrode layer 3 is embedded in the described In the L-shaped groove, an L-shaped insulating layer 2 is arranged between the L-shaped negative electrode layer 1 and the L-shaped positive electrode layer 3; the semiconductor laser die is installed on the inner surface of the L-shaped negative electrode ...

Embodiment 2

[0039] A laser plant lighting lamp as described in Embodiment 1, the difference is that the material of the L-shaped negative electrode layer 1 is single crystal silicon. The L-shaped anode layer 3 is made of monocrystalline silicon.

[0040] The material of the L-shaped insulating layer 2 is silicone grease. The silicone grease described is DX-9041 thermal conductive silicone grease, commonly known as heat dissipation paste, which has good thermal conductivity, temperature resistance, and insulation properties. It is an ideal dielectric material for heat-resistant devices, and its performance is stable, and it will not produce Corrosive gases that do not affect the metals they come in contact with.

Embodiment 3

[0042] A laser plant lighting lamp as described in Example 1, the difference is that the material of the L-shaped insulating layer is an insulating and heat-conducting adhesive, and the insulating and heat-conducting adhesive is a type of one-component room temperature vulcanized silicone adhesive. It has the characteristics of convenient use, high bonding strength, elastic body after curing, impact resistance, vibration, etc. At the same time, the cured product also has good heat conduction, heat dissipation functions, excellent high and low temperature resistance and electrical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com