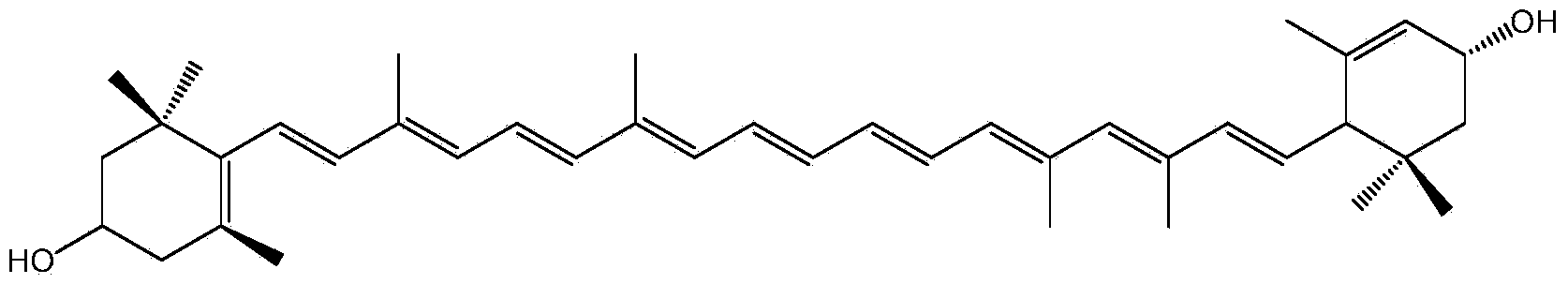

Modified xanthophyll production process and application of modified xanthophyll to aquatic feed

A lutein and modified technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of affecting water production, poor water solubility, adverse absorption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 5 kg of 95% (volume) ethanol and 3 kg of ethyl acetate mixed solution, heated at a temperature of about 60 ° C, adding 1 kg of lutein crystals with a content of 72% (weight), stirring and mixing at 1000-1200r / min for 20 minutes, lutein After the element crystals are completely dissolved, add 3 kg of polyethylene glycol glycerol ricinoleate, 1 kg of Tween 40, fully stir and mix for 50 minutes, add 5 kg of white carbon black, stir and mix, then add 54 kg of calcium carbonate powder, stir and mix Finally, obtain 72 kilograms of content and be 1% special-purpose lutein of aquatic products turn yellow feed.

Embodiment 2

[0026] 50 kg of ethyl acetate solution, heated to 55°C, added 10 kg of 81% lutein crystals, stirred and mixed at 1000-1200r / min for 15 minutes, after complete dissolution, added 10 kg of Span 20 and 8 kg of Tween 60, Fully stir and mix, add 40 kg of white carbon black, stir and mix, then add 100 kg of defatted rice bran and 197 kg of calcium carbonate powder to obtain 405 kg of lutein for aquatic yellowing feed with a content of 2%.

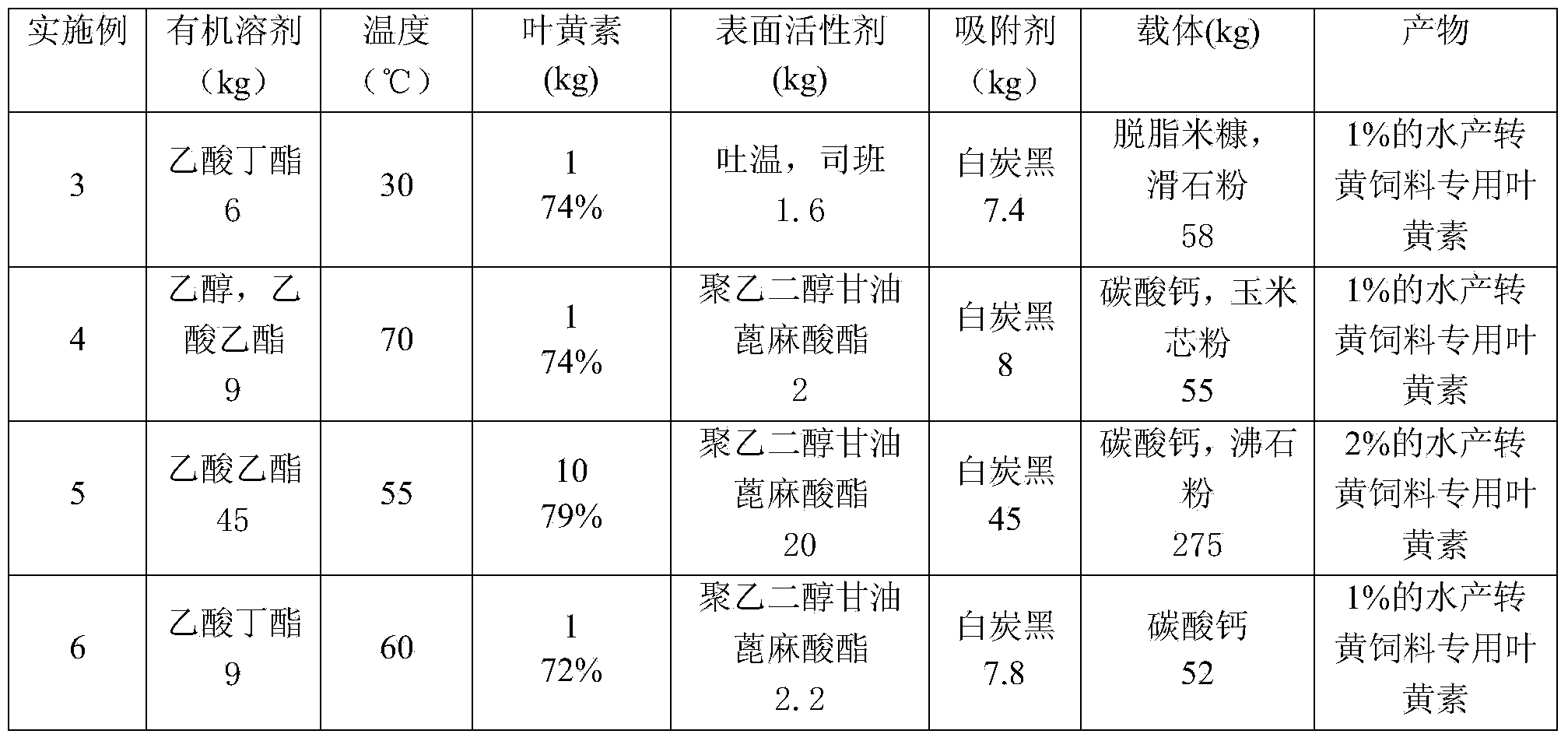

Embodiment 3-6

[0028] According to the method of Example 1, the special lutein for aquatic yellow turning feed was prepared, and the various components and dosages were as follows.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com