Method for regenerating dry harmful mediator

A medium and dry technology, applied in the direction of separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of difficult disposal of hazardous waste, and achieve the effects of easy operation, reduced discharge, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

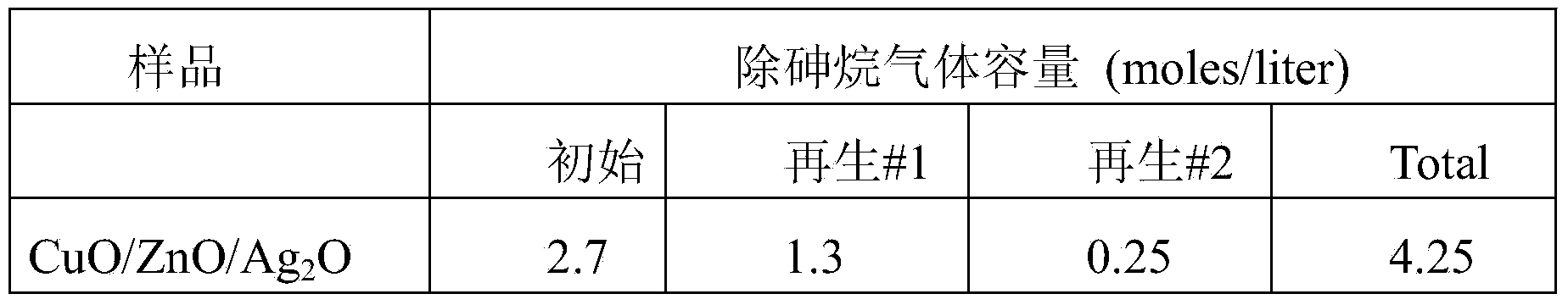

Embodiment 1

[0023] Fill a 3 liter metal container with 2.5 liters of CuO / Ag cylinders with a diameter of 1.6mm 2 The medium of O. Introduce arsine gas with a concentration of 10,000ppmv into the container from bottom to top at a speed of 0.013m / s. When the arsine gas concentration at the outlet above the container reaches 50ppmv, stop the gas supply. Calculate the arsine removal capacity of the medium in the container according to the reaction time and arsine concentration. Then air is injected into the container from top to bottom with a compressor pump at a flow rate of 1 liter per minute. The temperature of the outer wall and the center of the container will gradually rise due to the exothermic reaction. Therefore, the air flow is constantly adjusted to maintain the temperature in the center of the vessel below 300°C. Air injection was continued until the reaction was complete and the temperature of the vessel dropped to 30°C. Close the activation gas line. Use the above conditio...

Embodiment 2

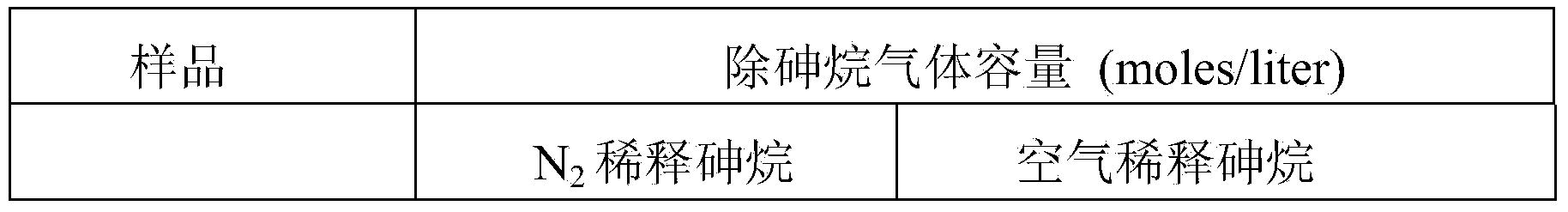

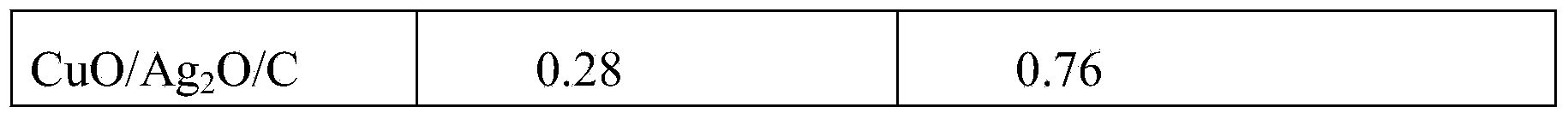

[0027] Fill a 200mL metal container with 100mL CuO / Ag containing 1~1.5mm blocks 2 Mediator of O / activated carbon. Introduce arsine gas diluted with nitrogen with a concentration of 9000ppmv into the container from bottom to top at a speed of 0.28m / s. When the concentration of arsine gas at the outlet above the container reaches 3ppmv, stop the gas supply. Calculate the reaction capacity of the medium in the container based on the reaction time and the concentration of arsine. Repeat the above experiment. This time the arsine was diluted with air instead of nitrogen to determine how well the vehicle was activated with air while removing arsenic. Table 2 records the arsine removal capacity of the media in the two experiments. Without replacing any media and equipment, the simultaneous air regeneration method increased the arsine removal capacity of the same volume of media by 2.7 times.

[0028] Table 2

[0029]

[0030]

[0031] The harmful gas is adsorbed and conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com