Preposed denitrification aeration biofilter and method for treating sewage

A biological aerated filter and pre-denitrification technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increased operating costs, low treatment efficiency, and low cost and other issues to achieve the effect of increasing the contact time and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

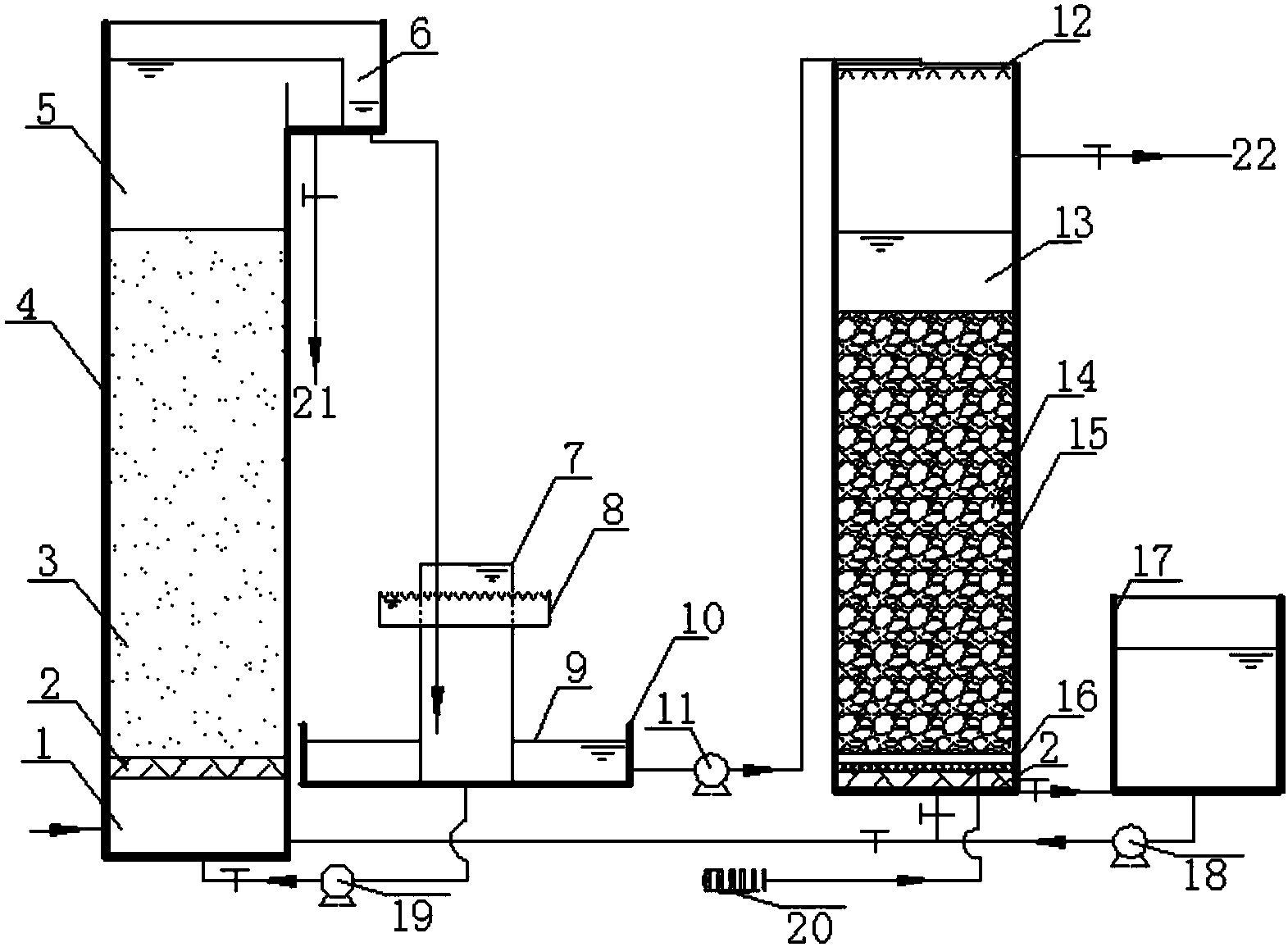

[0035] Such as figure 1 As shown, a pre-denitrification biological aerated filter includes a DN pool body 4 and a CN pool body 15, and also includes a first water storage tank body 10, a second water storage tank body 17 and an aeration pump 20; the DN pool body 4. The interior includes clean water area 5, sea sand filter material layer 3, supporting layer 2 and water distribution buffer zone 1 from top to bottom; water inlet is provided on one side of water distribution buffer zone 1; The water tank 6, the water outlet tank 6 and the clean water area 5 are separated by a water baffle, and the height of the water baffle is lower than the height of the top of the DN pool body 4; one side of the clean water area 5 is also provided with a DN pool backwash drain pipe 21 ; The middle part of the first water storage tank body 10 is placed with a first water storage tank inner cylinder 7; the outer side of the first water storage tank inner cylinder 7 is provided with an annular wate...

Embodiment 2

[0047] Same as Example 1, the difference is that the sea sand filter material layer 3 has a thickness of 1.5m; the zeolite packing layer 14 has a thickness of 1.6m.

Embodiment 3

[0049] Same as Example 1, the difference is that the sea sand filter material layer 3 has a thickness of 1.7m; the zeolite packing layer 14 has a thickness of 1.4m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com