Method for recovering progesterone from progesterone production mother liquor

A technology of progesterone and mother liquor, applied in the direction of steroids, organic chemistry, etc., can solve environmental hazards and other problems, achieve the effects of reducing pollution, reducing emissions, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

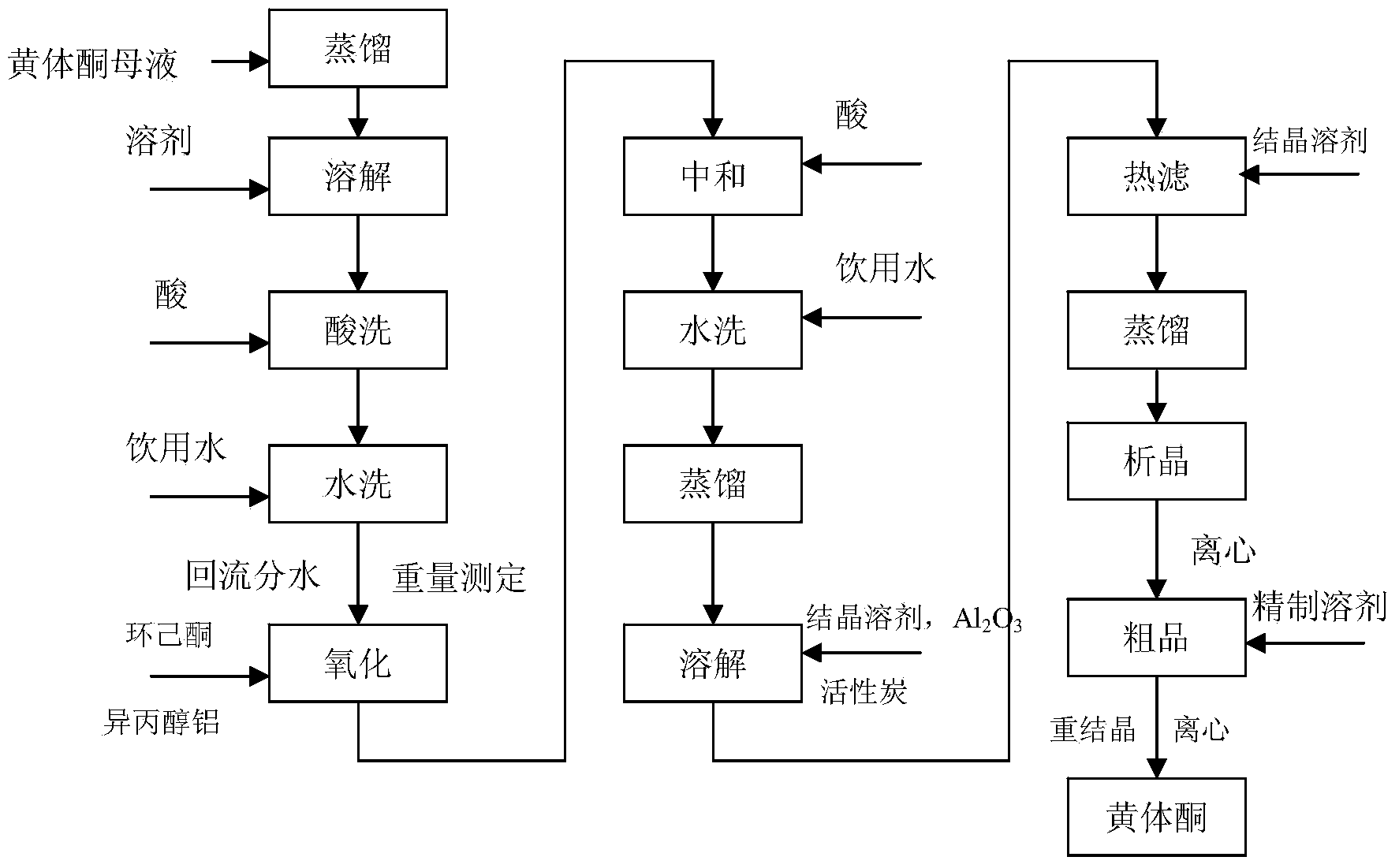

Method used

Image

Examples

Embodiment 1

[0033] 1] Mother liquor pretreatment:

[0034] 1.1] 200kg of the progesterone production mother liquor is pumped into the reaction tank and distilled. The end temperature of the distillation is 90°C, and 150kg of solvent is evaporated, so the residue weight M1 is 50kg; The crude product mother liquor produced in the oxidation production process;

[0035] 1.2] Add 50kg of toluene to the residue and raise the temperature to 70-80°C to completely dissolve the residue. Toluene can be replaced by one or more of benzene, chloroform, and methylene chloride;

[0036] 2) Remove some impurities: add 50kg of dilute hydrochloric acid solution with a concentration of 5% by mass, stir for 30 minutes, let it stand for 30 minutes, separate the layers, separate the acid layer, and repeat the pickling operation once; wash the toluene layer with 50kg of water, Repeat the operation 2 times until the pH>6. The dilute hydrochloric acid solution can be replaced with one or more of dilute sulfuric...

Embodiment 2

[0050] 1] Mother liquor pretreatment

[0051]1.1] 500kg of the progesterone production mother liquor is pumped into the reaction tank and distilled. The end temperature of the distillation is 95°C, and 378kg of solvent is evaporated; the residue weight is 122kg; Refined mother liquor produced in the oxidation production process;

[0052] 1.2] Add 250kg of toluene to the residue and raise the temperature to 70-80°C to completely dissolve the residue. Toluene can be replaced by one or more mixtures of benzene, chloroform, and methylene chloride.

[0053] 2) Remove some impurities: add 250kg of dilute sulfuric acid solution with a concentration of 5% by mass, stir for 30 minutes, let stand for 30 minutes, separate the layers, and separate the acid layer; repeat the pickling operation once; wash the toluene layer with 250kg of water 3 times, to PH>6. The dilute sulfuric acid solution can be replaced with one or more of dilute hydrochloric acid, dilute acetic acid and dilute for...

Embodiment 3

[0067] 1] Mother liquor pretreatment

[0068] 1.1] 1950kg of the progesterone production mother liquor is pumped into the reaction tank and distilled. The end temperature of the distillation is 100°C, and 1602kg of solvent is evaporated; then the residue weight M1 is 348kg; The mother liquor produced in the oxidation production process is a mixture of crude mother liquor and refined mother liquor;

[0069] 1.2] Add 1392kg of toluene to the residue and raise the temperature to 70-80°C to completely dissolve the residue. Toluene can be replaced by one or more mixtures of benzene, chloroform, and methylene chloride.

[0070] 2] Remove some impurities: add 1392 kg of dilute hydrochloric acid solution with a concentration of 10% by mass, stir for 30 minutes, let stand for 30 minutes, separate the layers, and separate the acid layer; repeat the pickling operation once; wash the toluene layer 2 with 700 kg of water times, to PH>6. The dilute hydrochloric acid solution can be repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com