Preparation method of carrageenan oligosaccharides

A technology of carrageenan oligosaccharide and glue solution, which is applied in the field of preparation of carrageenan oligosaccharide, can solve the problems of high cost, low solubility, stability and safety, achieve strong destructive power and avoid uneven product strength , the effect of small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

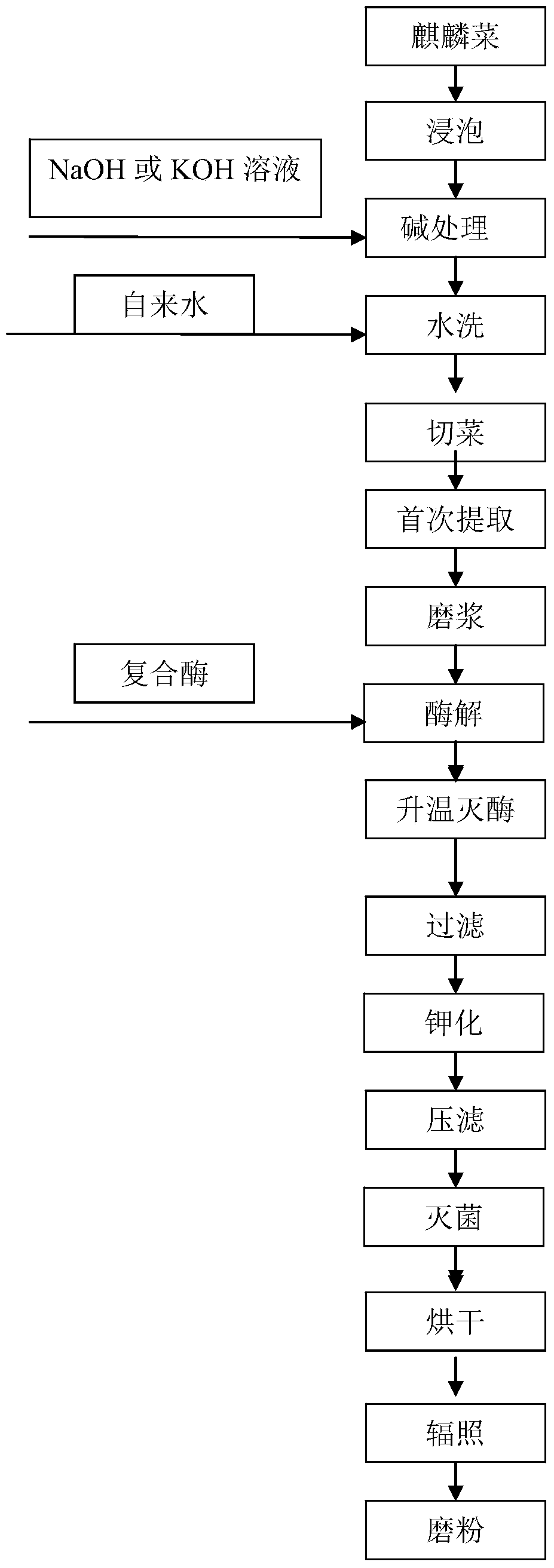

Method used

Image

Examples

Embodiment 1

[0055] 1. Raw material pretreatment process

[0056] 1.1 Prepare 15 tons of 8% NaOH solution according to the quality of Eucheuma spinach, and heat it to 60°C, turn on the stirring and add 5% KCl, after it is completely dissolved, put it into a pot with 2 tons of spinach, and keep the temperature constant Soak for 4 hours. After soaking for 4 hours, put the lye into the recovery tank and pump it into the heating pot after sedimentation. Add water to spray the vegetables so that the total amount of lye is about 14 tons, and then add an appropriate amount of 30% lye to make the lye contain 8% (use the neutralization titration method to measure the lye content of the mother liquor, and calculate the amount of lye added). alkalinity).

[0057] 1.2 After the lye is prepared, the temperature starts to rise, and KCl is properly supplemented according to the glue retention of the hairy vegetables, 25kg per pot.

[0058] 1.3 Washing: for the first washing, use three times of recycle...

Embodiment 2

[0106] 1. Raw material pretreatment process

[0107] 1.1 Prepare 15 tons of 10% NaOH solution according to the quality of Eucheuma spinach, and heat it to 70°C, turn on the stirring and add 8% KCl, after it is completely dissolved, pour it into a pot with 2 tons of spinach, and keep the temperature constant Soak for 4 hours. After soaking for 4 hours, put the lye into the recovery tank and pump it into the heating pot after sedimentation. Add water to spray the vegetables so that the total amount of lye is about 14 tons, and then add an appropriate amount of 30% lye to make the lye contain 10% (use the neutralization titration method to measure the lye content of the mother liquor, and calculate the amount of lye added). alkalinity).

[0108] 1.2 After the lye is prepared, the temperature starts to rise, and KCl is properly supplemented according to the glue retention of the hairy vegetables, 50kg per pot.

[0109] 1.3 Washing: for the first washing, use three times of recy...

Embodiment 3

[0157] 1. Raw material pretreatment process

[0158] 1.1 Prepare 15 tons of 9% NaOH solution according to the quality of Eucheuma spinach, and heat it to 65°C, turn on the stirring and add 7% KCl, after it is completely dissolved, pour it into a pot with 2 tons of spinach, and keep the temperature constant Soak for 4 hours. After soaking for 4 hours, put the lye into the recovery tank and pump it into the heating pot after sedimentation. Add water to spray the vegetable body, so that the total amount of lye is about 14 tons, and then add an appropriate amount of 30% lye to make the lye contain 9% (use the neutralization titration method to measure the lye content of the mother liquor, and calculate the amount of lye added). alkalinity).

[0159] 1.2 After the lye is prepared, the temperature starts to rise, and KCl is properly supplemented according to the glue retention of the hairy vegetables, 40kg per pot.

[0160] 1.3 Washing: for the first washing, use three times of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com