Heat treatment method for recovering performance of K465 alloy turbine blade

A heat treatment method and technology of turbine blades, applied in the field of metallurgy, can solve problems such as no precedent for K465 alloy turbine blade performance recovery, and achieve strong operability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

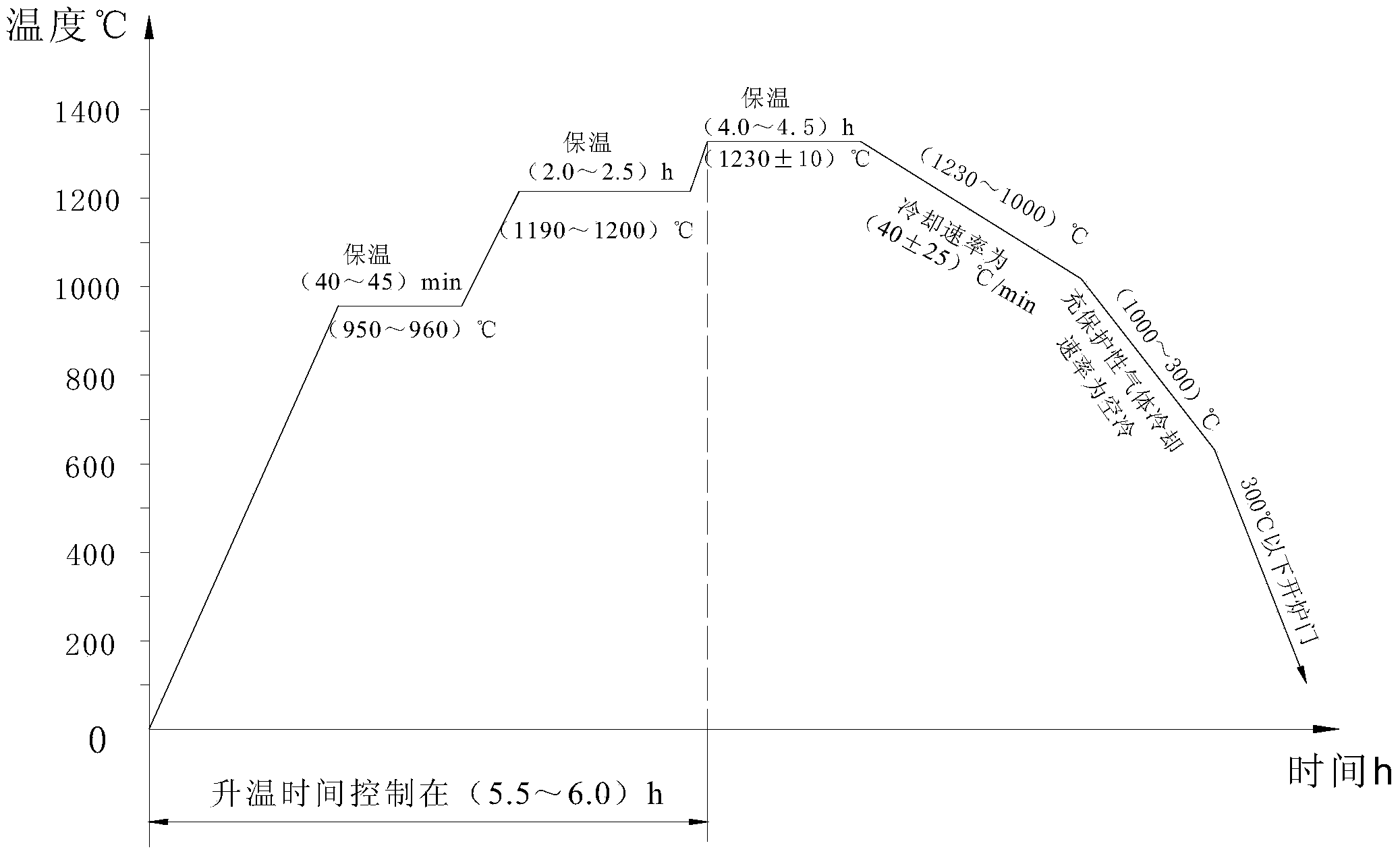

[0029] A K465 alloy turbine blade recovery performance heat treatment method is carried out according to the following steps:

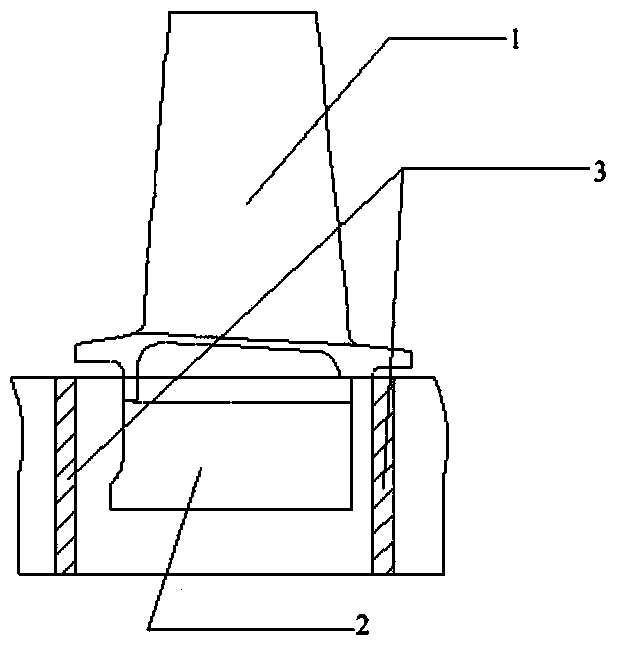

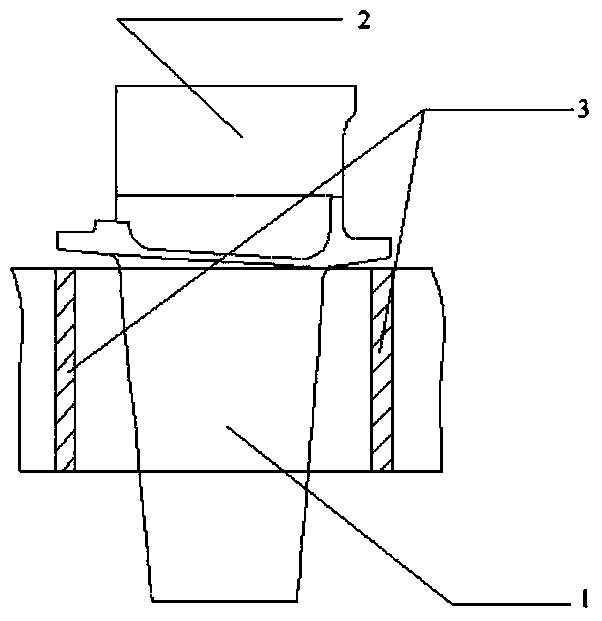

[0030] (1) Blade loading: Put the K465 alloy turbine blades that have served for one life into the vacuum furnace perpendicular to the surface of the fixture; figure 1 or figure 2 shown;

[0031] (2) Heat preservation after heating up with the furnace: under the protection of inert gas, the vacuum furnace is powered from room temperature, heated and heated up with the furnace, kept at 950 ° C ~ 960 ° C for 40 minutes, kept at 1190 ° C ~ 1200 ° C for 2.5 hours, and heated from room temperature To 1230°C, the entire heating time should be controlled within 6.0h; keep warm at 1230°C for 4h;

[0032] (3) Cool down with the furnace: Cool from 1230°C to 1000°C at a cooling rate of 40±25°C / min, and cool with inert gas partial pressure; at 1000°C, fill inert gas and cool to 300°C, the cooling rate is equivalent For air cooling, the air cooling pressure is...

Embodiment 2

[0040] Example 2 is basically the same as Example 1, the difference is: (2) heat preservation after heating up with the furnace: under vacuum, the vacuum furnace is powered from room temperature, heated and heated up with the furnace, and kept at 950 ° C ~ 960 ° C for 45 minutes. Keep warm at 1190°C~1200°C for 2 hours, heat from room temperature to 1230°C, the whole heating time should be controlled within 5.5h; keep warm at 1230°C for 4.5h,

[0041] After K465 alloy undergoes recovery heat treatment at 1230℃ for 4.5h, its microstructure is Figure 4 (b) transforms into Figure 4 (e), its mechanical properties are shown in Table 3; the morphology of intragranular γ′ is restored from polygonal or flower basket to cubic, and its morphology is more square than that before heat treatment. It can be seen from Table 3 that its mechanical properties meet the requirements of technical conditions.

[0042] Table 3 Mechanical properties after heat treatment

[0043]

[0044]Aft...

Embodiment 3

[0046] Example 3 is basically the same as Example 1, the difference is: (2) heat preservation after heating up with the furnace: under vacuum, the vacuum furnace is powered from room temperature, heated and heated up with the furnace, and kept at 950 ° C ~ 960 ° C for 43 minutes. Insulate at 1190°C~1200°C for 2.2 hours, heat from room temperature to 1230°C, the entire heating time should be controlled within 5.7 hours; keep at 1230°C for (4~4.5) hours.

[0047] After testing, after heat treatment for recovery performance, the morphology of intragranular γ′ recovers from polygonal or flower basket shape to cubic shape, which is more square than before heat treatment for recovery performance. Its mechanical properties meet the requirements of technical conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com