Method for producing organic acid

A manufacturing method and organic acid technology, applied in the preparation of organic compounds, organic chemistry, carboxylate preparation, etc., can solve the problems of polymer property degradation, damage to commodity value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

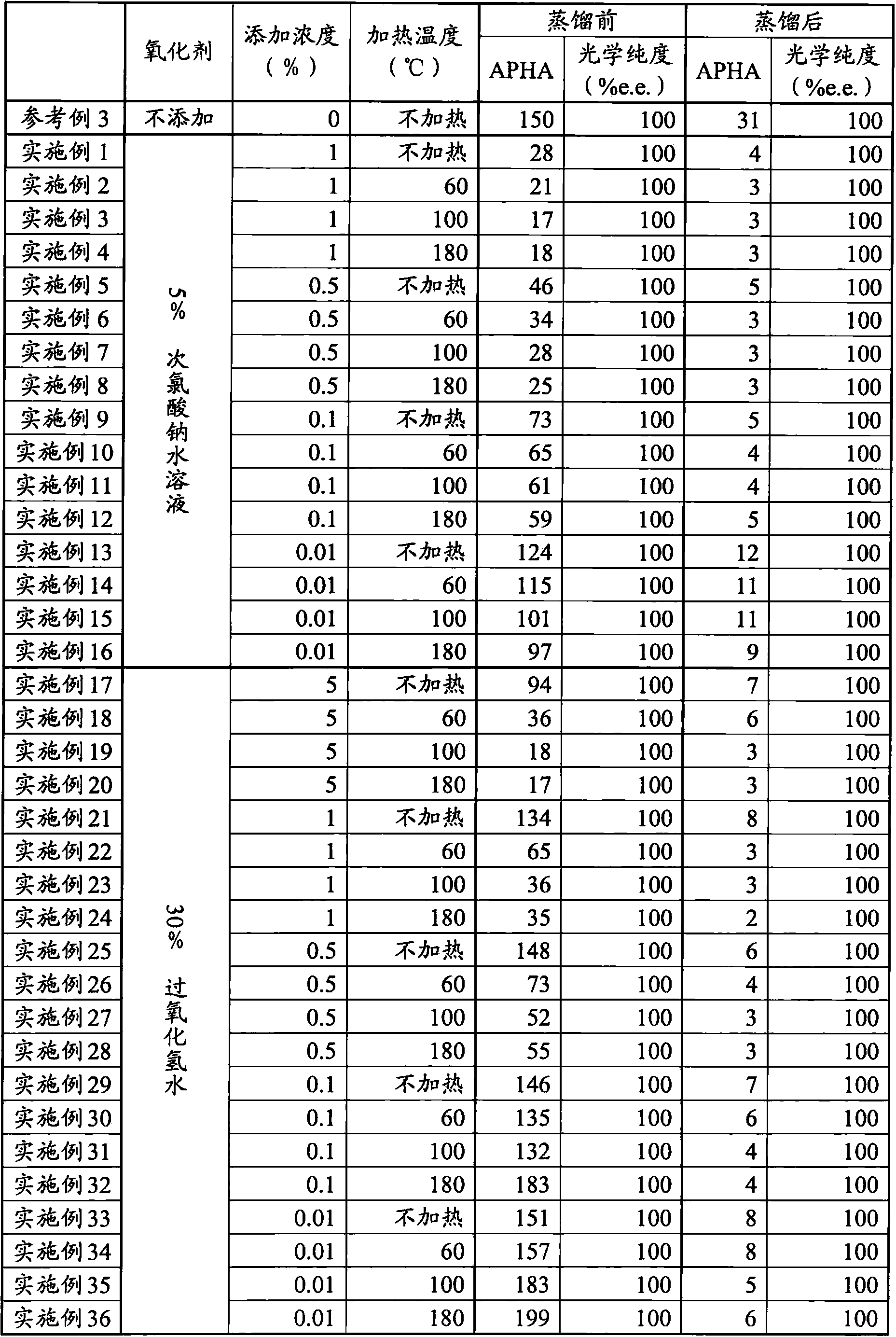

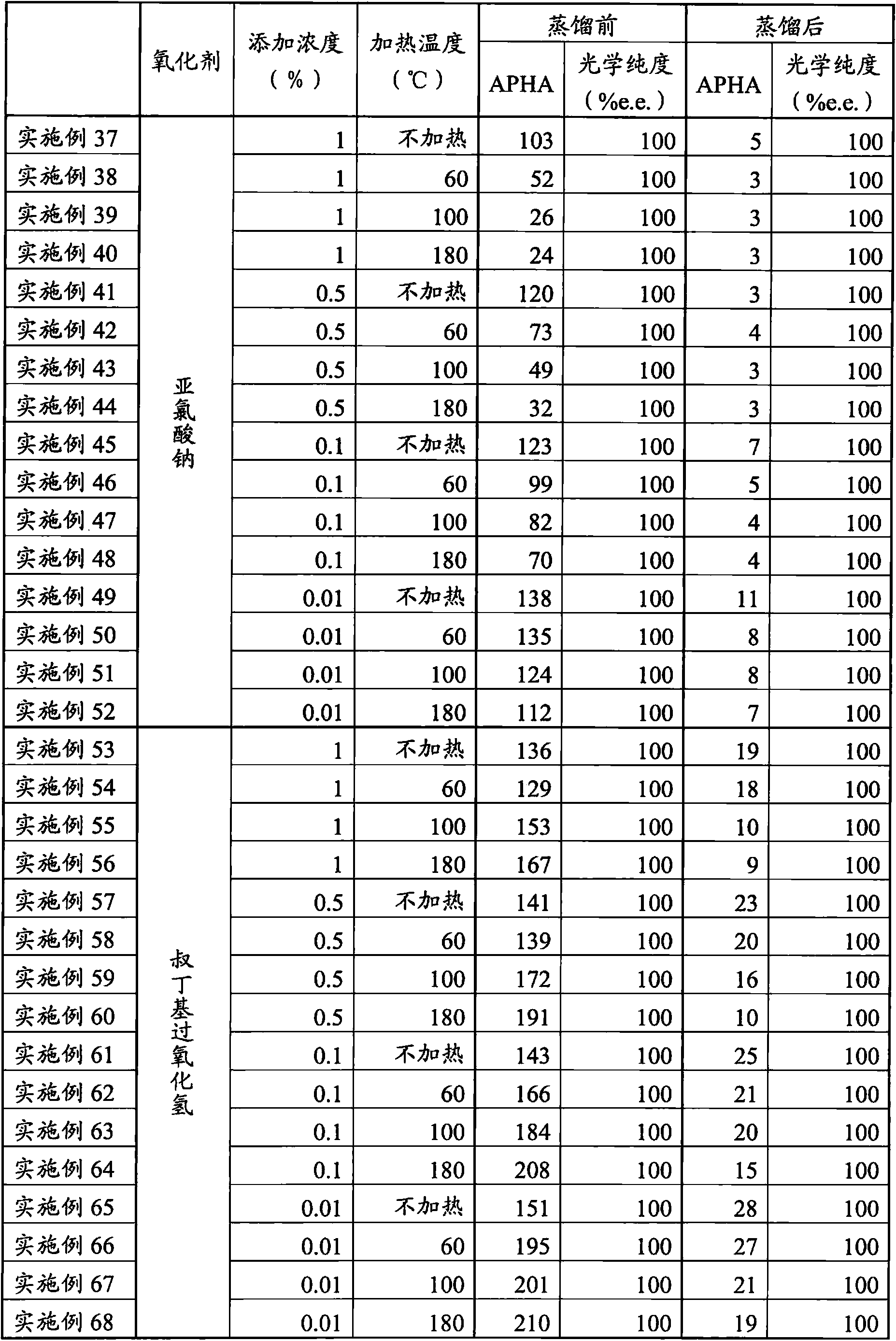

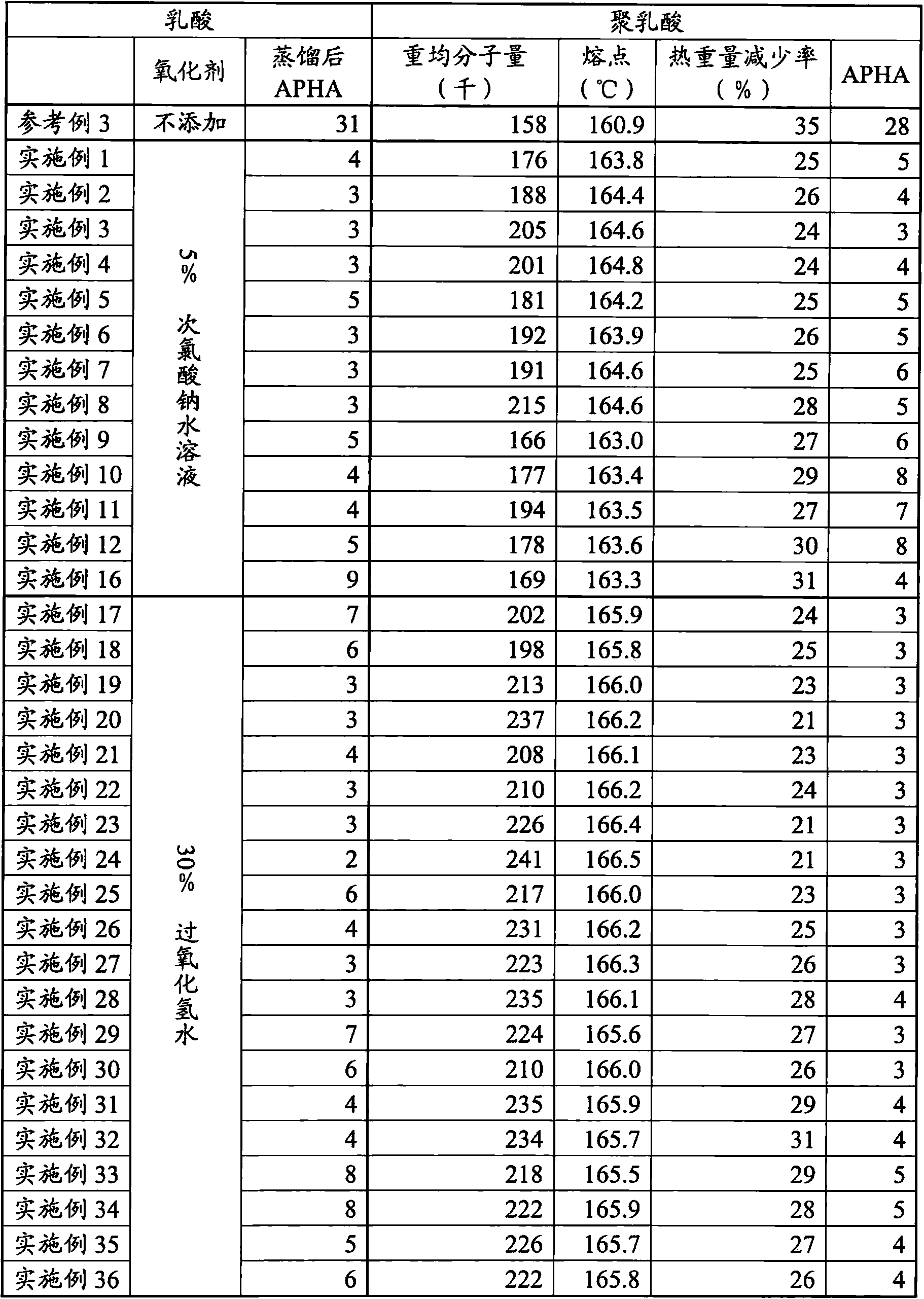

Examples

Embodiment

[0054] Hereinafter, the present invention will be described with reference to examples, but the present invention is not limited to the following examples.

reference example 1

[0055] (Reference Example 1) Yeast strain having L-lactic acid fermentation ability

[0056] As a microorganism for producing L-lactic acid, HI003, which is an L-lactic acid fermenting yeast strain described in Reference Example 1 of WO2009 / 099044, was used.

reference example 2

[0057] (Reference Example 2) Production of L-lactic acid by batch fermentation

[0058] Using the HI003 strain of Reference Example 1, a raw sugar medium (70 g / L "Usaccharin" (manufactured by MUSO Co., Ltd.), 1.5 g / L ammonium sulfate) was used to conduct a batch fermentation test using the following culture conditions and methods. In addition, the culture medium was used after autoclaving (121 degreeC, 15 minutes).

[0059] [Cultivation Conditions]

[0060] Reaction tank capacity (amount of lactic acid fermentation medium): 30 (L), temperature adjustment: 32 (℃), reaction tank ventilation: 0.1 (L / min), reaction tank stirring speed: 200 (rpm), pH adjustment: use 1N calcium hydroxide to adjust to pH 6.5.

[0061] [upbringing method]

[0062] The HI003 strain was shaken overnight in a test tube in 5 ml of a raw sugar medium (pre-culture). The pre-pre-culture solution was inoculated into 100 ml of fresh raw sugar medium, and cultured with shaking in a 500-ml Sakaguchi flask fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com