Graphene oxide/hydrotalcite composite antibacterial film material and preparation and application of graphene oxide/hydrotalcite composite antibacterial film material

A thin film material and composite antibacterial technology, applied in the field of antibacterial, can solve the problems of poor film formation and difficulty in preparing antibacterial coatings, and achieve the effect of ordered structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

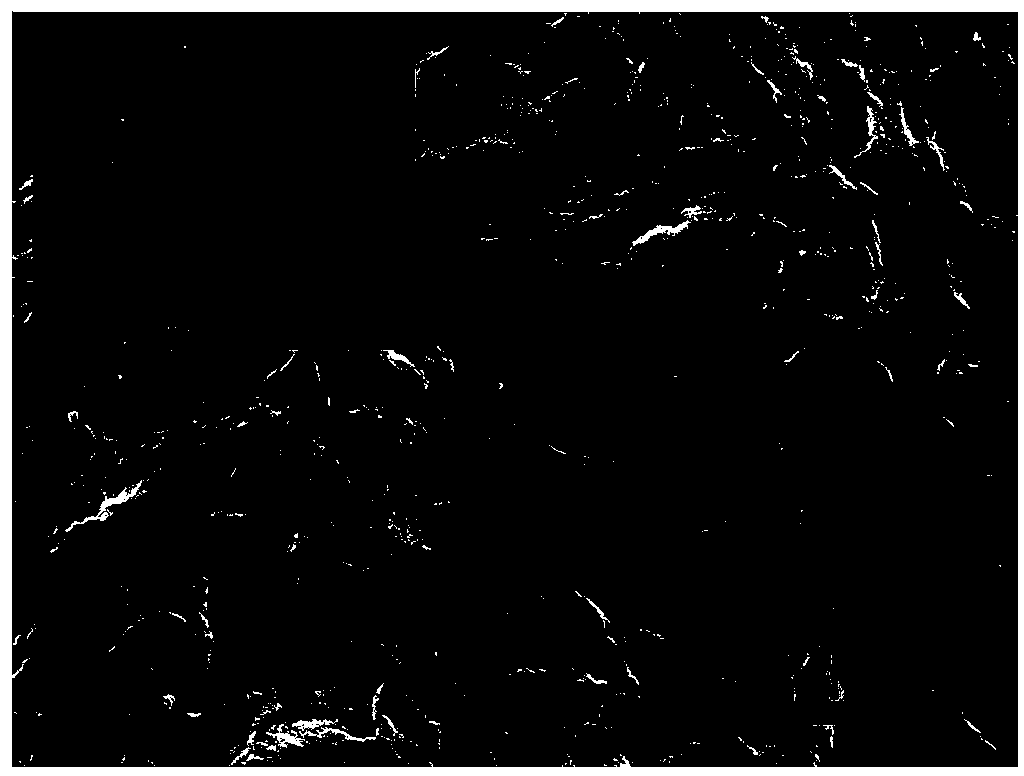

[0018] Preparation of graphene oxide solution: 1g natural graphite, 1g NaNO 3 Mix it with 50 mL of concentrated sulfuric acid and put it into a 250mL beaker, stir it magnetically for 4 hours in an ice bath at 0°C, then slowly add 6g of KMnO 4 Finally, remove the ice bath, stir at about 35°C for 2h under natural conditions, slowly add 90mL of water and stir for 15min in a water bath at 98°C, then add 200mL of warm water and 20mL of H 2 o 2 , transfer the liquid to a centrifuge tube, wash with HCl and water, and dry at 50°C for 48 h to obtain graphite oxide.

[0019] Weigh 0.2 g of graphite oxide and disperse it in a beaker with 100 mL of water, and ultrasonically peel off the graphite oxide to prepare a graphene oxide solution with a concentration of 2 mg / mL. This solution can be used as the original graphene oxide solution for subsequent experiments.

[0020] Preparation of penicillin anion intercalation hydrotalcite colloidal solution: the experimental water is just boiled...

Embodiment 1

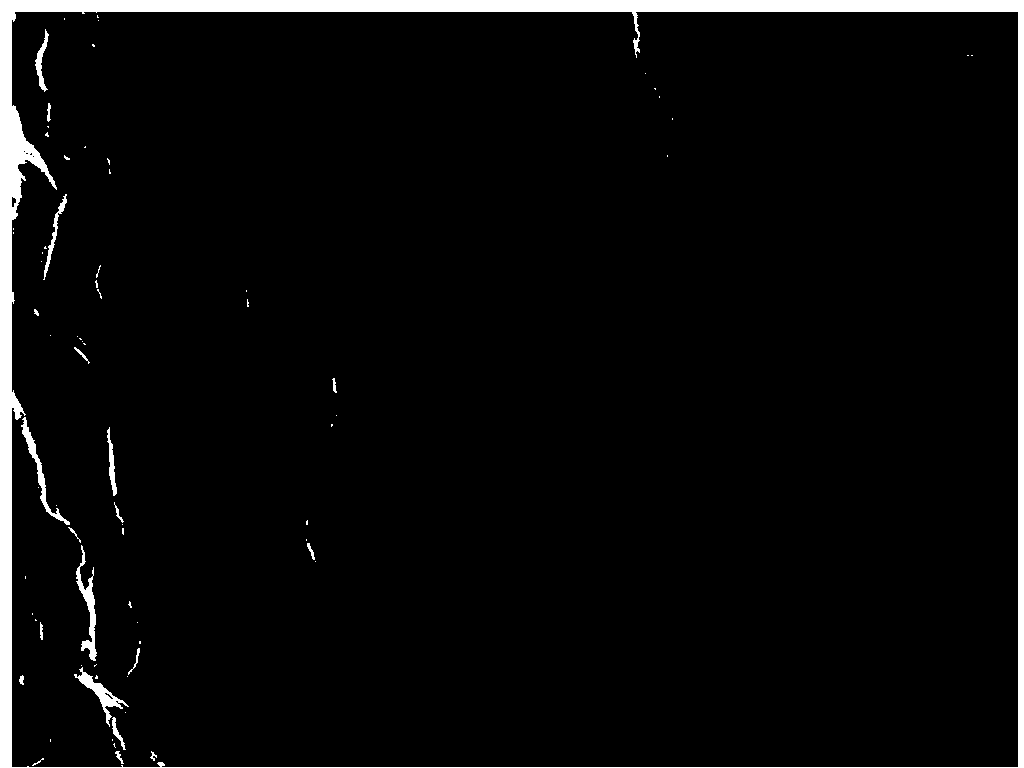

[0030] 1. Preparation of graphene oxide / hydrotalcite antibacterial nanocomposite film material

[0031] 1.1 Synthesis of graphene oxide solution

[0032] 1g of natural graphite, 1g of NaNO 3 Mix it with 50 mL of concentrated sulfuric acid and put it into a 250mL beaker, stir it magnetically for 4 hours in an ice bath at 0°C, then slowly add 6g of KMnO 4 Finally, remove the ice bath, stir at about 35°C for 2h under natural conditions, slowly add 90mL of water and stir for 15min in a water bath at 98°C, then add 200mL of warm water and 20mL of H 2 o 2, transfer the liquid to a centrifuge tube and wash with HCl and water centrifugally, and dry at 50°C for 48h to obtain graphite oxide. Weigh 0.2 g of graphite oxide and disperse it in a beaker with 100 mL of water, and ultrasonically peel off the graphite oxide to prepare a graphene oxide solution with a concentration of 2 mg / mL. This solution can be used as the original graphene oxide solution for subsequent experiments.

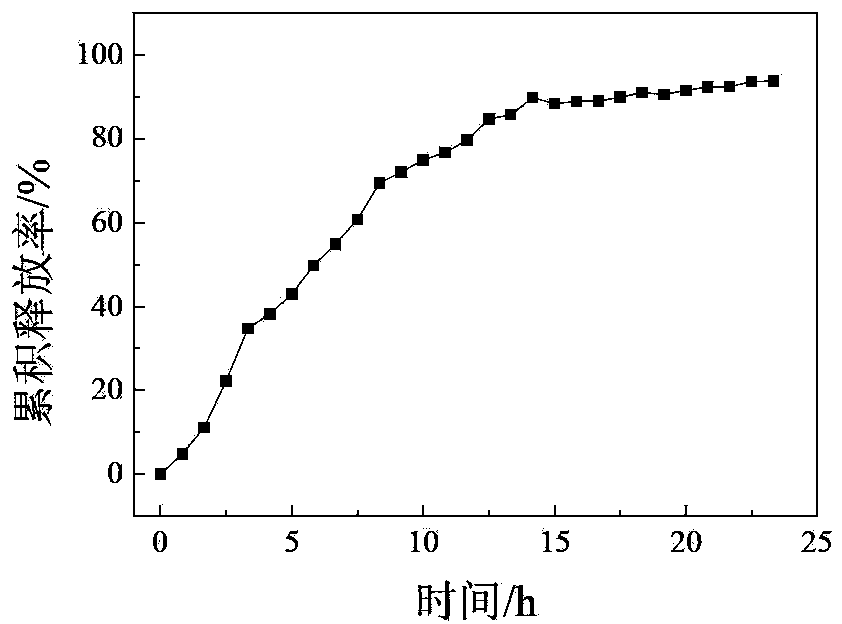

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com