High-protein low-fat yoghourt and preparation method thereof

A high-protein, low-fat technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as the protein content needs to be improved, the impact on the texture of the final product, and the bad flavor of the product, so as to achieve the control of product stability, excellent brightness, and Excellent flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

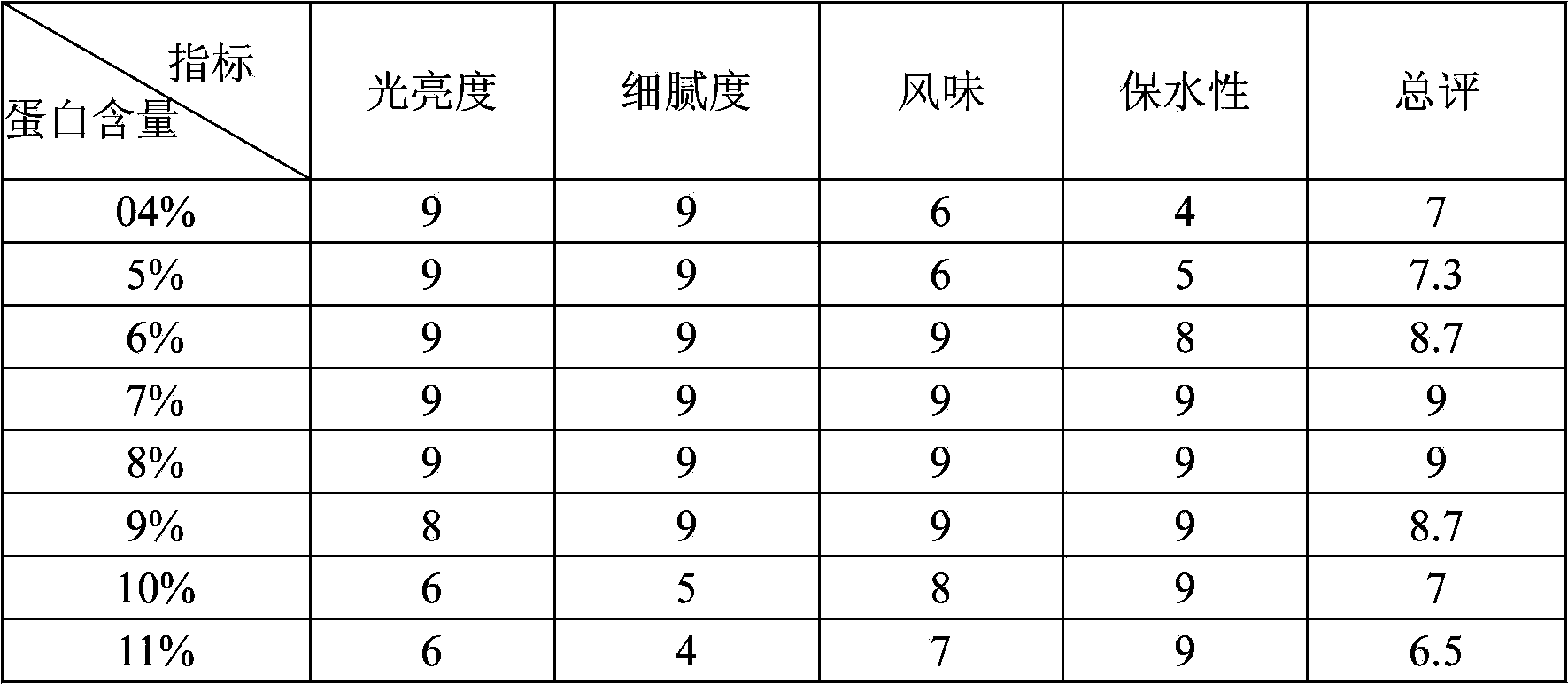

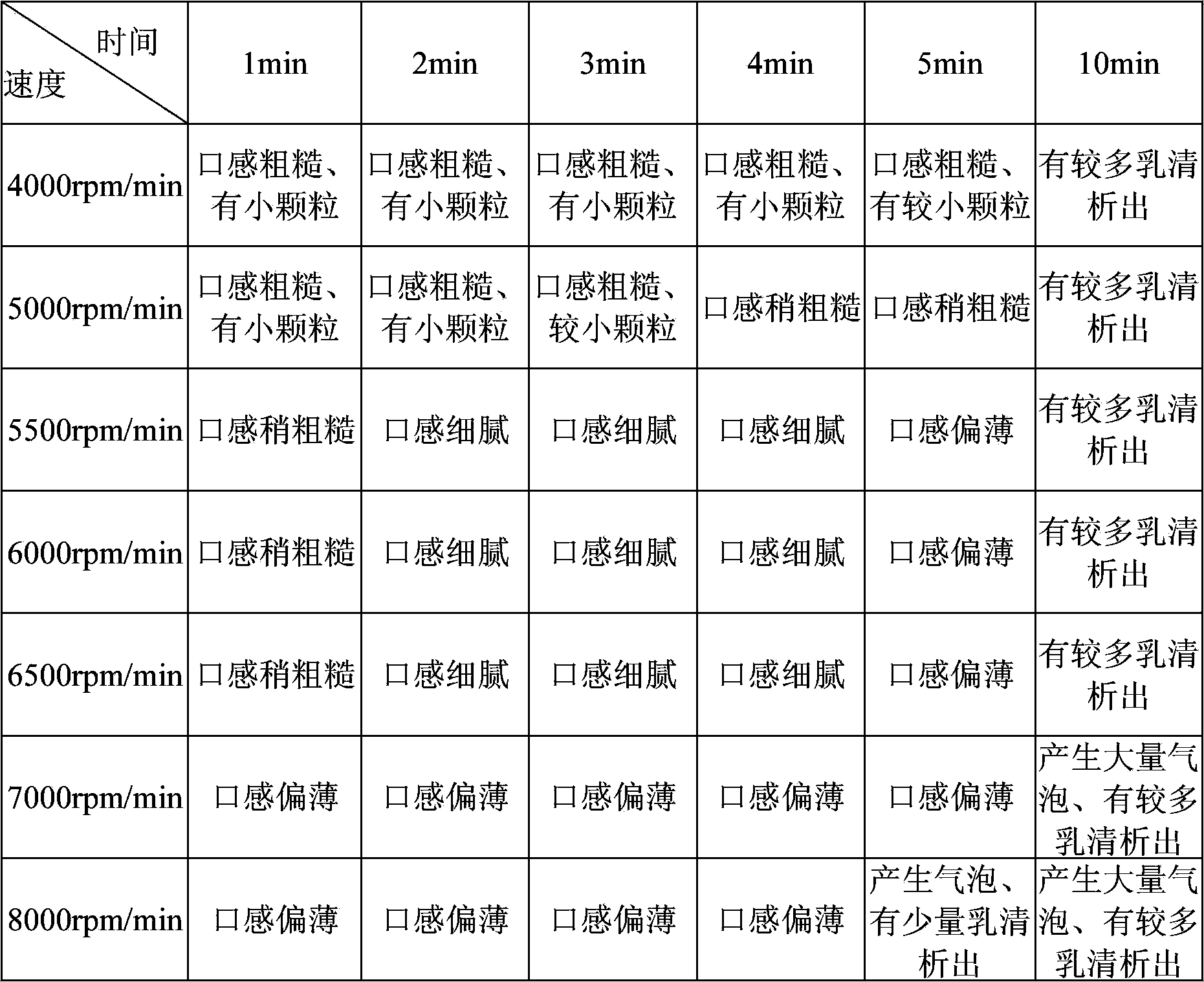

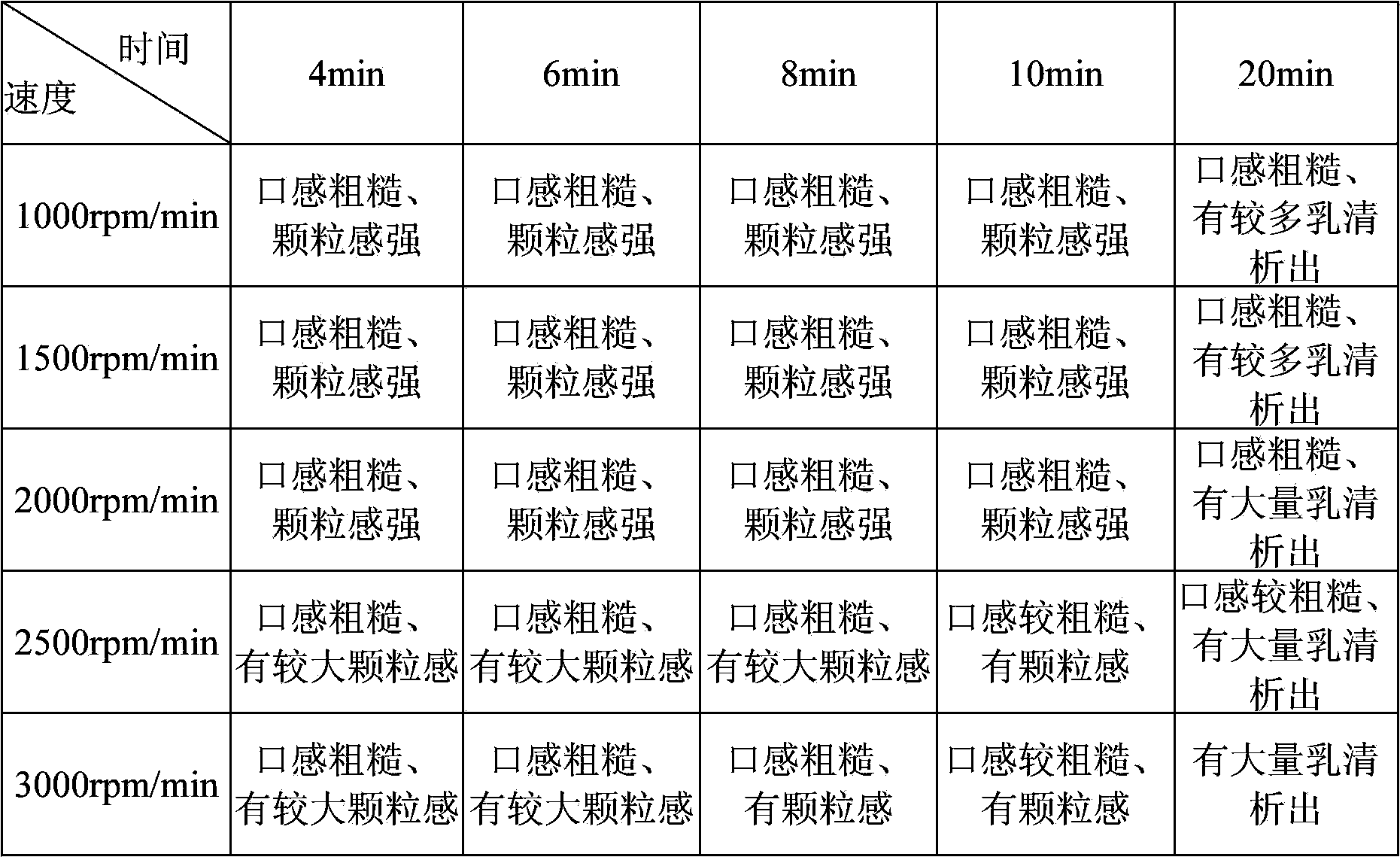

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a high-protein low-fat milk and a preparation method thereof.

[0045] The raw material composition of this yogurt comprises (in 1000g): low-fat milk: 900g; White granulated sugar: 50g; Milk protein powder (protein content is 60%, and wherein, casein content is 60%, whey protein content is 40%, Particle size is 10 μm): 55g; appropriate amount of Bifidobacterium infantis, Lactobacillus bulgaricus and Streptococcus thermophilus.

[0046] The making method of this yogurt comprises the following steps:

[0047] 1. Stir the above-mentioned low-fat milk, white sugar and milk protein powder at 65°C for 30 minutes to mix them evenly to obtain a mixed material;

[0048] 2. After degassing the mixed material, homogenize it at 65°C and 18MPa pressure;

[0049] 3. Sterilize the homogenized mixture at 95°C for 300s;

[0050] 4. Cool the sterilized material to 42°C, add an appropriate amount of the above-mentioned fermentation bacteria (Bifidobacterium inf...

Embodiment 2

[0056] This embodiment provides a high-protein low-fat milk and a preparation method thereof.

[0057] The raw material composition of this yogurt comprises (in 1000g): skimmed milk: 880g; White granulated sugar: 60g; Milk protein powder (protein content is 70%, wherein, casein content is 65%, whey protein content is 35%, granule Particle size is 9μm): 60g; appropriate amount of Lactobacillus bulgaricus and Streptococcus thermophilus.

[0058] The making method of this yogurt comprises the following steps:

[0059] 1. Stir the above skimmed milk, white sugar and milk protein powder at 70°C for 25 minutes to mix them evenly to obtain a mixed material;

[0060] 2. After degassing the mixed material, homogenize it at 68°C and 20MPa pressure;

[0061] 3. Sterilize the homogenized mixture at 110°C for 10 minutes;

[0062] 4. Cool the sterilized material to 43°C, add an appropriate amount of the above-mentioned fermentation strains (Lactobacillus bulgaricus and Streptococcus ther...

Embodiment 3

[0067] This embodiment provides a high-protein low-fat milk and a preparation method thereof.

[0068] The raw material composition of this yoghurt comprises (in 1000g): low-fat milk: 860g; White granulated sugar: 70g; Milk protein powder (protein content is 70%, and wherein, casein content is 70%, whey protein content is 30%, Particle size: 8 μm): 70 g; appropriate amount of Lactobacillus acidophilus, Lactobacillus bulgaricus and Streptococcus thermophilus.

[0069] The making method of this yogurt comprises the following steps:

[0070] 1. Stir the above-mentioned low-fat milk, white sugar and milk protein powder at 68°C for 25 minutes to mix them evenly to obtain a mixed material;

[0071] 2. After degassing the mixed material, homogenize it at 65°C and 20MPa pressure;

[0072] 3. Sterilize the homogenized mixed material at 121°C for 4s;

[0073] 4. Cool the sterilized material to 42°C, add an appropriate amount of the above-mentioned fermentation strains (Lactobacillus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com