Production method utilizing cassava stems, cassava residues and pasture to manufacture biological feed for beef cattle

A technology of biological feed and production method, which is applied in the production field of beef cattle feed, can solve the problems of high water content of forage grass, easy mold and deterioration, high labor intensity, etc., and achieve the goal of improving digestibility, improving palatability, and increasing aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

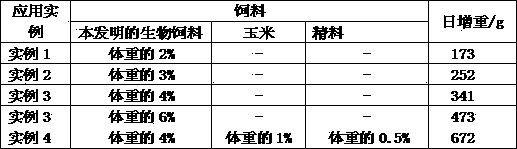

Embodiment 1

[0019] Crush the cassava stalks, cassava residues and royal bamboo grass with a pulverizer, pass through a sieve, and take granules between 2 and 10 meshes; add urea with 1% of the weight of the granules, mix evenly, and steam at 120 to 125°C for 30 to 60 minutes. Cool to below 30°C, add cassava stalks, cassava dregs and 1% Trichoderma viridis liquid culture solution by weight of pasture, and cultivate for 24 hours; ~48h; finally add cassava stalks, cassava residues and a lactic acid bacteria liquid culture solution of 1% by weight of pasture, seal for at least 7 days, and obtain biological feed for beef cattle.

[0020] The production method of the above-mentioned Trichoderma viride liquid culture solution: add glucose 20g, potassium dihydrogen phosphate 2g and ammonium sulfate 5g for every 1 liter of potato extract, insert Trichoderma viride bacterial classification after conventional sterilization, shake table culture 16h; The production method of Trichoderma korningen liqu...

Embodiment 2

[0022] The cassava stalks, cassava residues and elephant grass are crushed with a pulverizer, passed through a sieve, and the particles between 2 and 10 mesh are taken, and 1% of the particle weight is added with urea. Below ℃, add cassava stalks, cassava residues and pasture grass weight 2% Trichoderma green liquid culture solution, and cultivate for 24 hours; then add cassava stalks, cassava residues and pasture grass weight 2% Trichoderma corning liquid culture solution, and cultivate for 24-48 hours; Finally, add cassava stalks, cassava residues and a lactic acid bacteria liquid culture solution of 2% by weight of forage grass, and seal it for at least 7 days to obtain a beef cattle biological feed;

[0023] The production method of Trichoderma viride liquid culture liquid, Trichoderma korningi liquid culture liquid and lactic acid bacteria liquid culture liquid is with embodiment 1.

Embodiment 3

[0025] The cassava stalks, cassava residues, king bamboo grass and elephant grass are crushed with a grinder, passed through a sieve, and the particles between 2 and 10 mesh are taken, and 1% urea of the particle weight is added, mixed evenly, and steamed at 120 to 125°C for 60 minutes , cooled to below 30°C, adding cassava stalks, cassava residues and forage grass weight 2% Trichoderma green liquid culture solution, cultivated for 24 hours; 24 to 48 hours; finally add cassava stalks, cassava residues and a lactic acid bacteria liquid culture solution with 2% weight of forage grass, and seal it for at least 7 days to obtain a biological feed for beef cattle;

[0026] The production method of Trichoderma viride liquid culture liquid, Trichoderma korningi liquid culture liquid and lactic acid bacteria liquid culture liquid is with embodiment 1.

[0027]

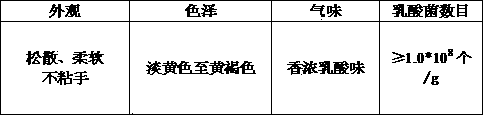

[0028] The quality index of the beef cattle biological feed of gained of the present invention is as follows:

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com