Tea egg preparation method

A production method and technology for tea eggs, which are applied in the field of food processing, can solve the problems of dry egg yolk in tea leaves and insufficient nutrition of eggs, and achieve the effects of delicious taste, rich nutritional value and extended shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Production of tea eggs 1

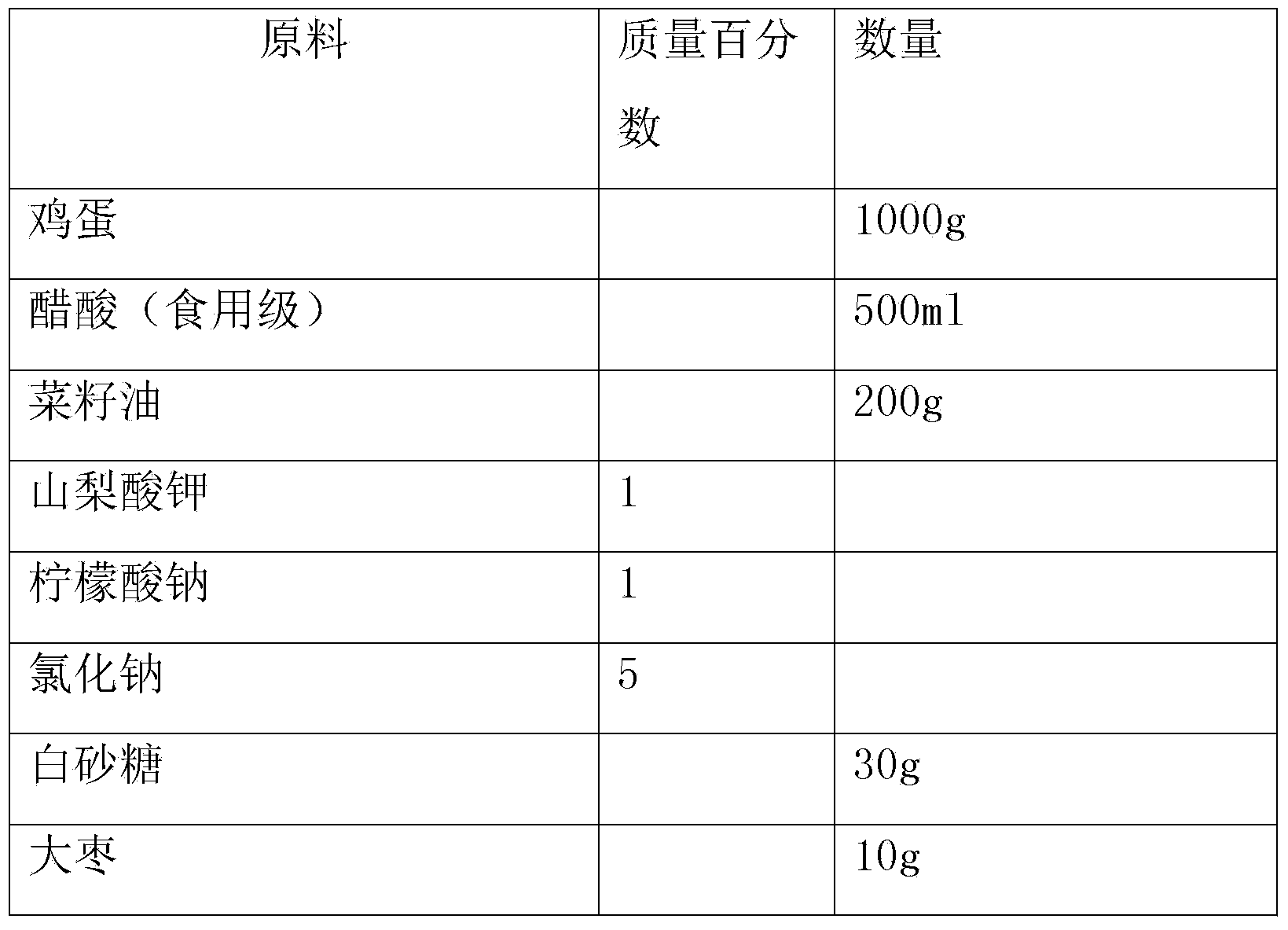

[0026] Ingredients formula:

[0027]

[0028]

[0029] The specific production steps are as follows:

[0030] (1) Choose fresh eggs, clean the surface with an acetic acid solution with a pH of 6, and then rinse 3 times with water;

[0031] (2) Coat the surface of cleaned eggs with cooking oil, the thickness of the oil layer is 50um;

[0032] (3) Put the eggs obtained in the previous step into an incubator with a nitrogen pressure of 0.7mpa and a temperature of 45 degrees to dry for 30 minutes;

[0033] (4) Put the eggs obtained in the previous step into a closed container with a saline solution containing potassium sorbate and sodium citrate and a pressure of 0.5 mpa, and let stand for 1 hour, in which the mass fraction of potassium sorbate is 1%, The mass fraction of sodium citrate is 1%, and the mass fraction of sodium chloride is 5%;

[0034] (5) Add 30g of tea, 20g of Codonopsis, 10g of wolfberry, 5g of hawthorn, 5g of orange peel, 5g of c...

Embodiment 2

[0038] Example 2: Production of tea eggs 2

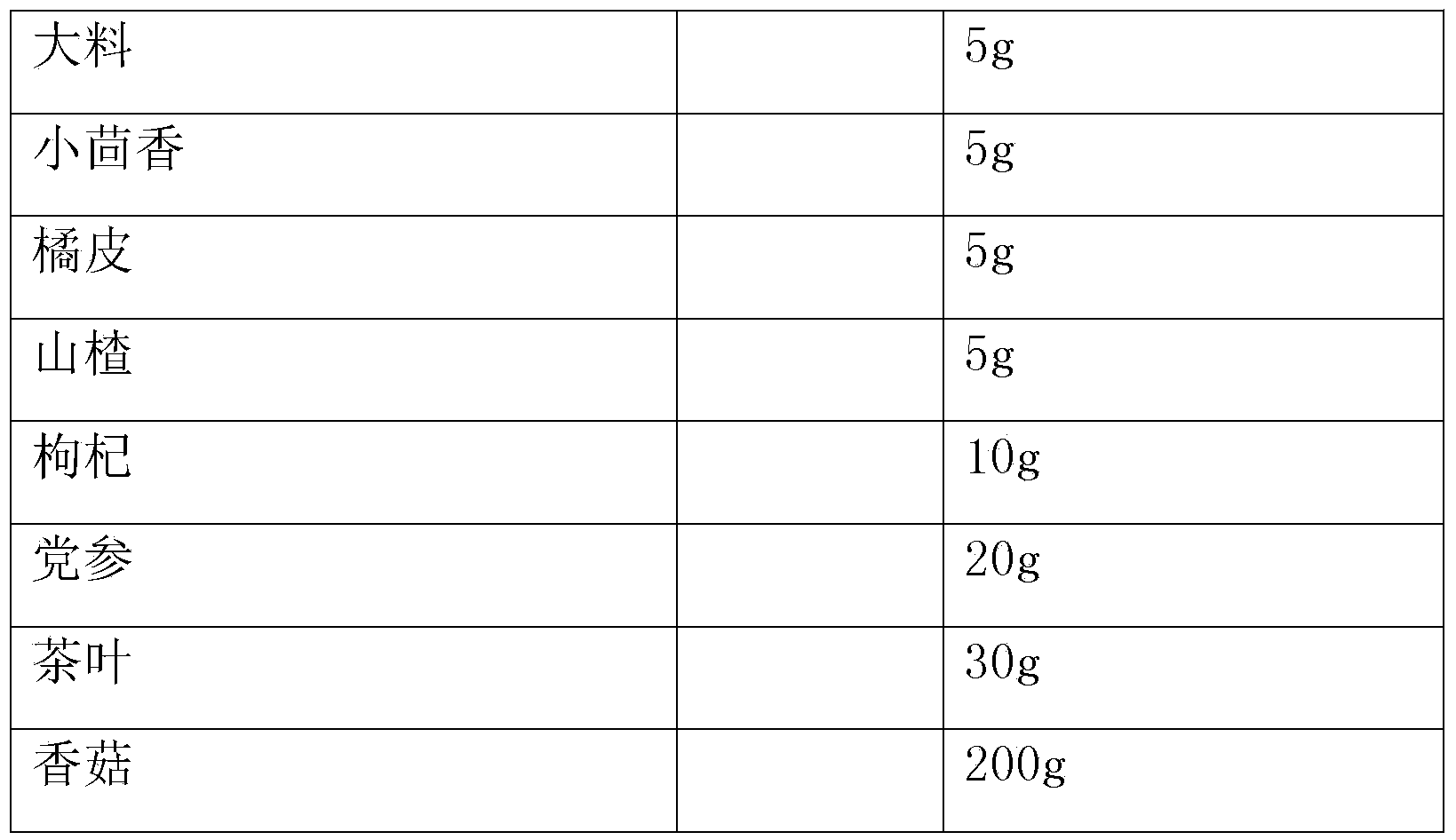

[0039] Ingredients formula:

[0040]

[0041] The specific production steps are as follows:

[0042] (1) Choose fresh eggs, clean the eggs with food grade acetic acid solution with a pH of 6, and then clean them with water for 3 times;

[0043] (2) Coat the surface of cleaned eggs with cooking oil, the thickness of the oil layer is 70um;

[0044] (3) Put the eggs in the previous step into a constant temperature box with a nitrogen pressure of 0.5 mpa and a temperature of 45 degrees for 25 minutes;

[0045] (4) Put the eggs obtained in the previous step into a closed container with a saline solution containing potassium sorbate and sodium citrate and a pressure of 0.6mpa, and let stand for 1 hour, in which the mass fraction of potassium sorbate is 1%, The mass fraction of sodium citrate is 1%, and the mass fraction of sodium chloride is 7%;

[0046] (5) Add 30g of tea, 20g of Codonopsis, 10g of wolfberry, 5g of hawthorn, 5g of orange peel, 5g o...

Embodiment 3

[0050] Example 3: Production of tea eggs 3

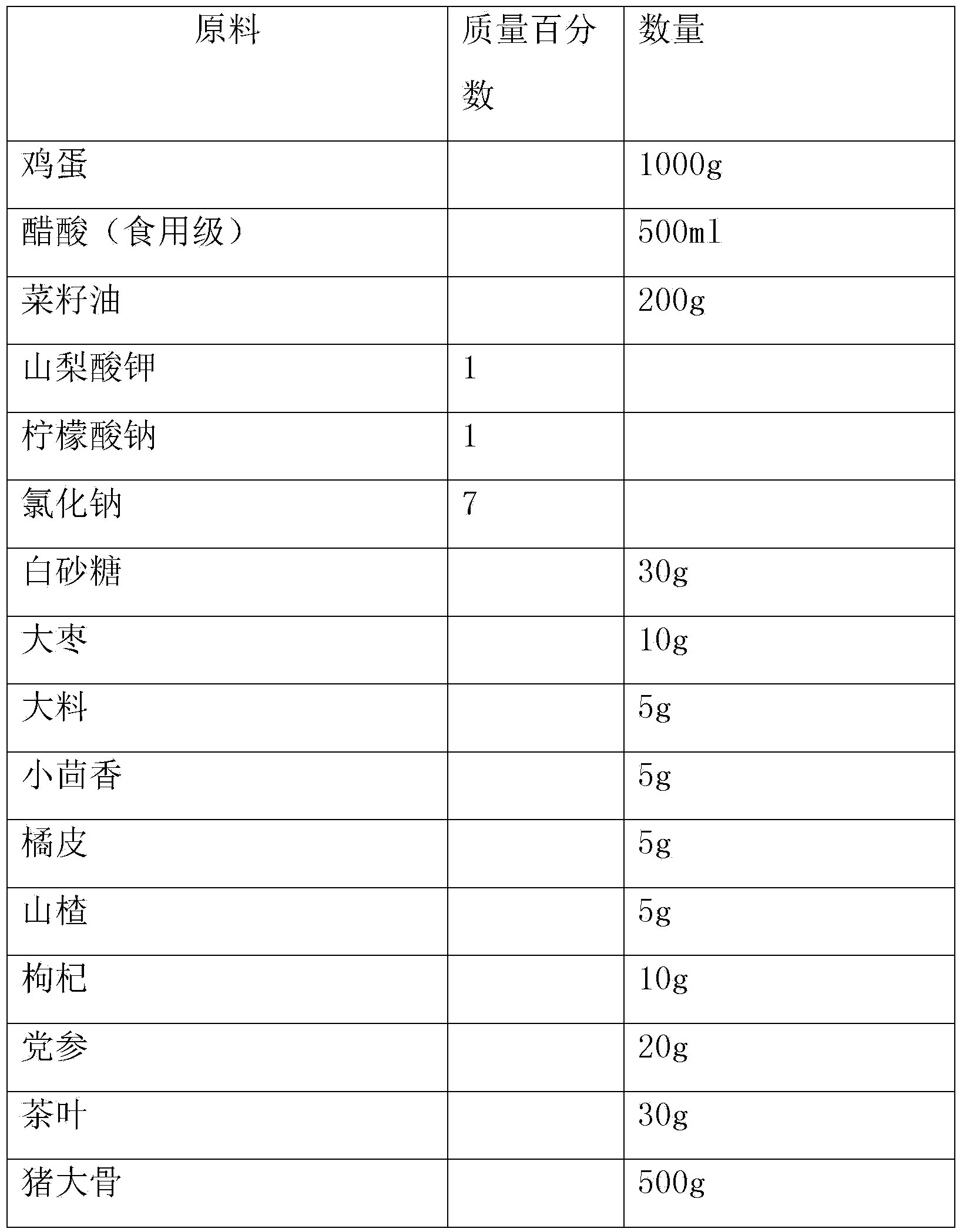

[0051] Ingredients formula:

[0052]

[0053]

[0054] The specific production steps are as follows:

[0055] (1) Choose fresh eggs, clean the surface with food grade acetic acid with a pH of 5, and then rinse with water for 3 times;

[0056] (2) Coat the surface of cleaned eggs with cooking oil, the thickness of the oil layer is 80um;

[0057] (3) Put the eggs from the previous step into a constant temperature oven with a nitrogen pressure of 0.6 mpa and a temperature of 50 degrees for 40 minutes;

[0058] (4) Put the eggs obtained in the previous step into a closed container with a saline solution containing potassium sorbate and sodium citrate and a pressure of 0.55mpa, and let stand for 1 hour, in which the mass fraction of potassium sorbate is 1%, The mass fraction of sodium citrate is 1%, and the mass fraction of sodium chloride is 10%;

[0059] (5) Add 30g tea leaves, 20g Codonopsis pilosula, 10g wolfberry, 5g hawthorn, 5g orange peel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com