Pharmaceutical composition containing lisinopril and amlodipine besylateand preparation method of pharmaceutical composition

A technology of amlodipine besylate and a composition, applied in the field of medicine, can solve the problems of low production efficiency, long drying time, low drying temperature and the like, and achieve the effects of high production efficiency, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of Lisinopril Amlodipine Tablets

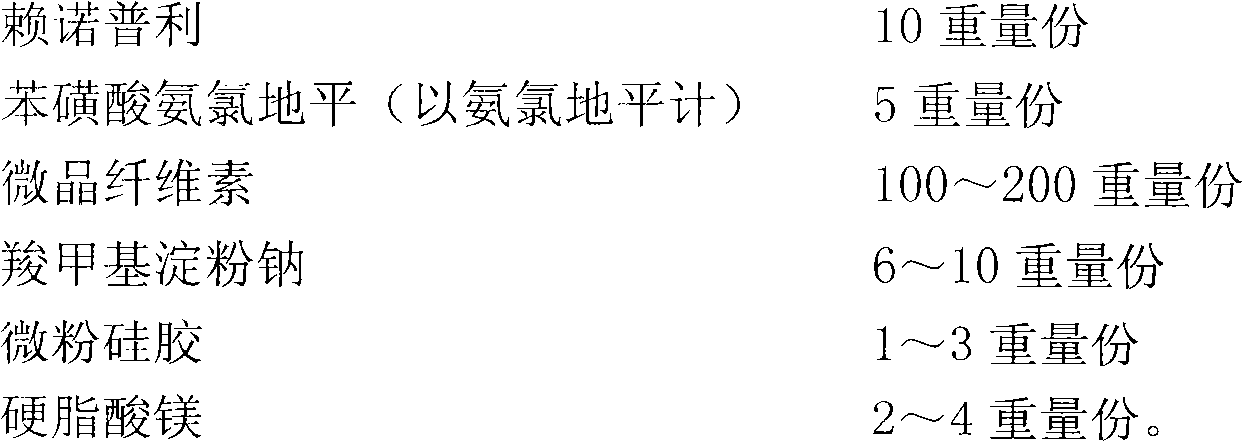

[0034] 1. Prescription

[0035]

[0036] 2. Preparation method

[0037] (1) Pulverize lisinopril and amlodipine besylate respectively, pass through an 80-mesh sieve, and set aside;

[0038] (2) microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel and magnesium stearate are passed through a 60-mesh sieve respectively, and set aside;

[0039] (3) Lisinopril, amlodipine besylate, microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel and magnesium stearate of 2 / 3 prescription quantity are taken by weighing prescription quantity, mix;

[0040] (4) the mixed material that step (3) is obtained is crossed 40 mesh sieves;

[0041] (5) mixing the sieved material in step (4);

[0042] (6) the mixed material obtained in step (5) is granulated by a dry granulator;

[0043] (7) take by weighing the magnesium stearate of 1 / 3 recipe quantity, join in the granule tha...

Embodiment 2

[0045] Embodiment 2: Preparation of Lisinopril Amlodipine Tablets

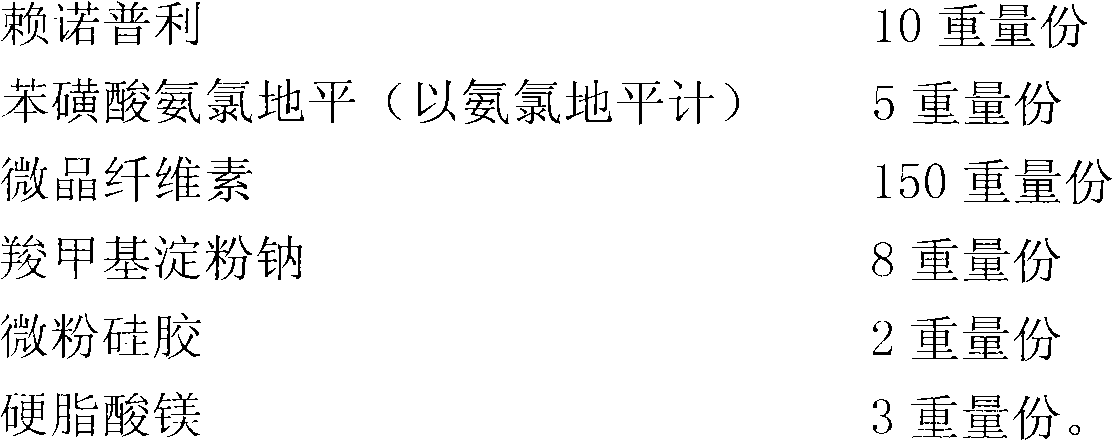

[0046] 1. Prescription

[0047]

[0048] 2. Preparation method

[0049] (1) Pulverize lisinopril and amlodipine besylate respectively, pass through a 100-mesh sieve, and set aside;

[0050] (2) Microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel and magnesium stearate are passed through a 50-mesh sieve respectively, and set aside;

[0051] (3) Lisinopril, amlodipine besylate, microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel and magnesium stearate of 2 / 3 prescription quantity are taken by weighing prescription quantity, mix;

[0052] (4) the mixed material that step (3) is obtained is crossed 50 mesh sieves;

[0053] (5) mixing the sieved material in step (4);

[0054] (6) the mixed material obtained in step (5) is granulated by a dry granulator;

[0055] (7) take by weighing the magnesium stearate of 1 / 3 recipe quantity, join in the granule tha...

Embodiment 3

[0057] Embodiment 3: the preparation of lisinopril amlodipine tablet

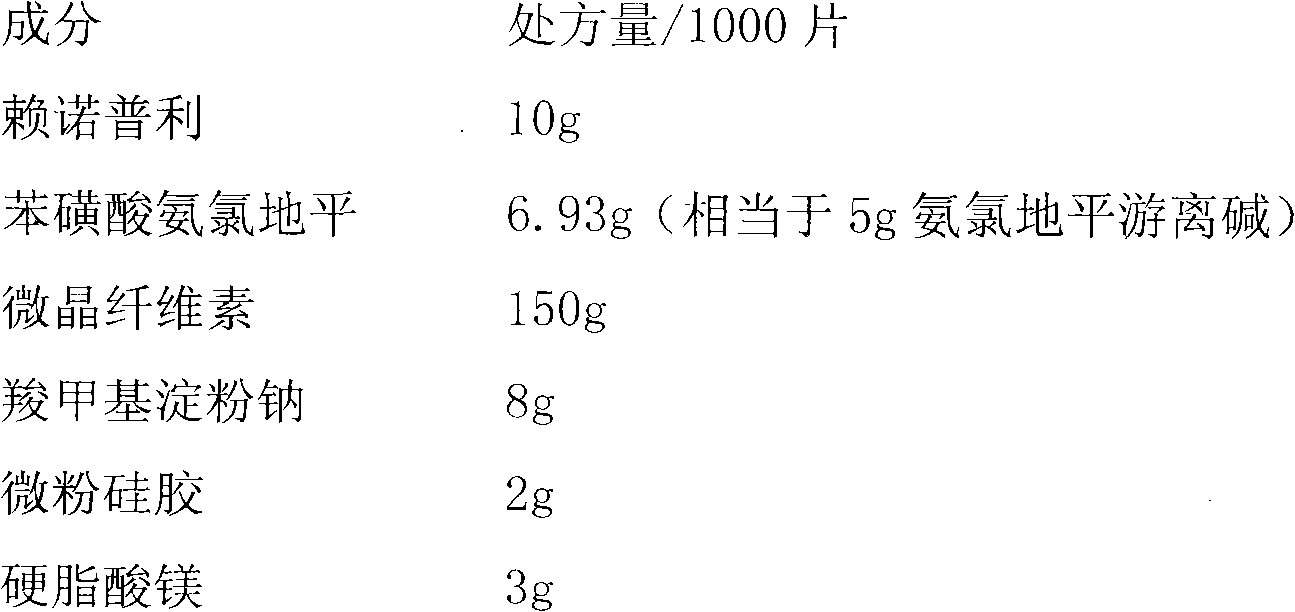

[0058] 1. Prescription

[0059]

[0060] 2. Preparation method

[0061] (1) Pulverize lisinopril and amlodipine besylate respectively, pass through a 120 mesh sieve, and set aside;

[0062] (2) microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel and magnesium stearate are passed through a 60-mesh sieve respectively, and set aside;

[0063] (3) Lisinopril, amlodipine besylate, microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel and magnesium stearate of 2 / 3 prescription quantity are taken by weighing prescription quantity, mix;

[0064] (4) the mixed material that step (3) is obtained is crossed 60 mesh sieves;

[0065] (5) mixing the sieved material in step (4);

[0066] (6) the mixed material obtained in step (5) is granulated by a dry granulator;

[0067] (7) take by weighing the magnesium stearate of 1 / 3 recipe quantity, join in the granule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com