Method for preparing individual porous thyroid cartilage support

A thyroid cartilage and software technology, applied in the field of preparation of personalized porous thyroid cartilage scaffolds, can solve the problem of inability to meet patients' personalized needs for the shape of the scaffold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

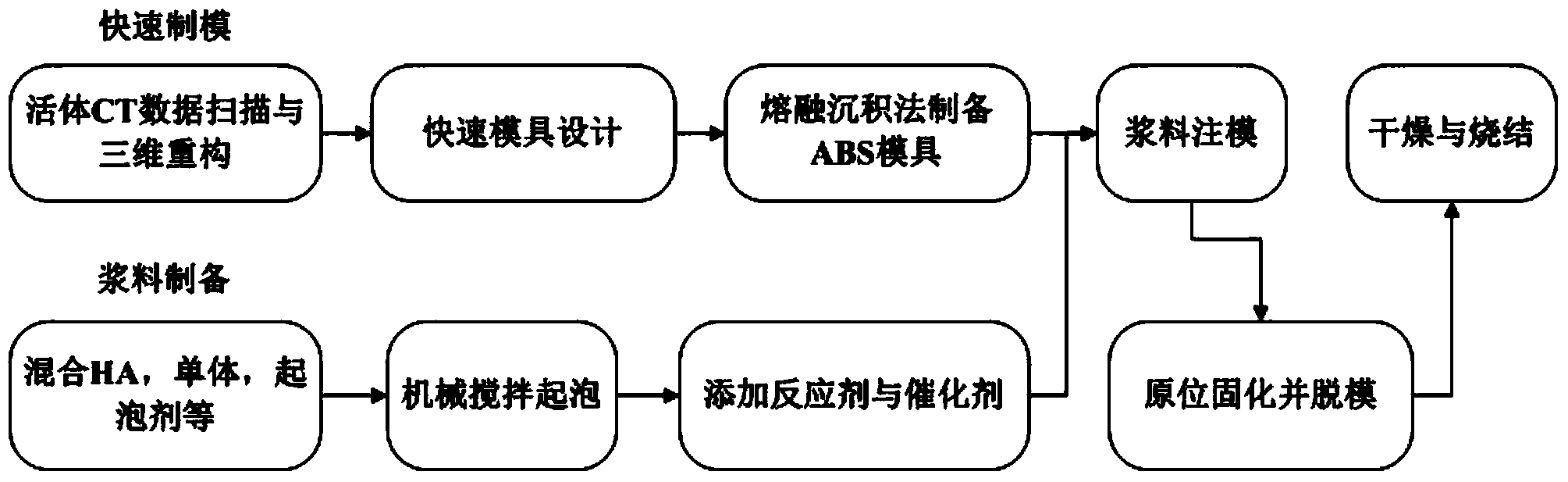

[0046] The preparation method of the personalized porous thyroid cartilage scaffold is as follows:

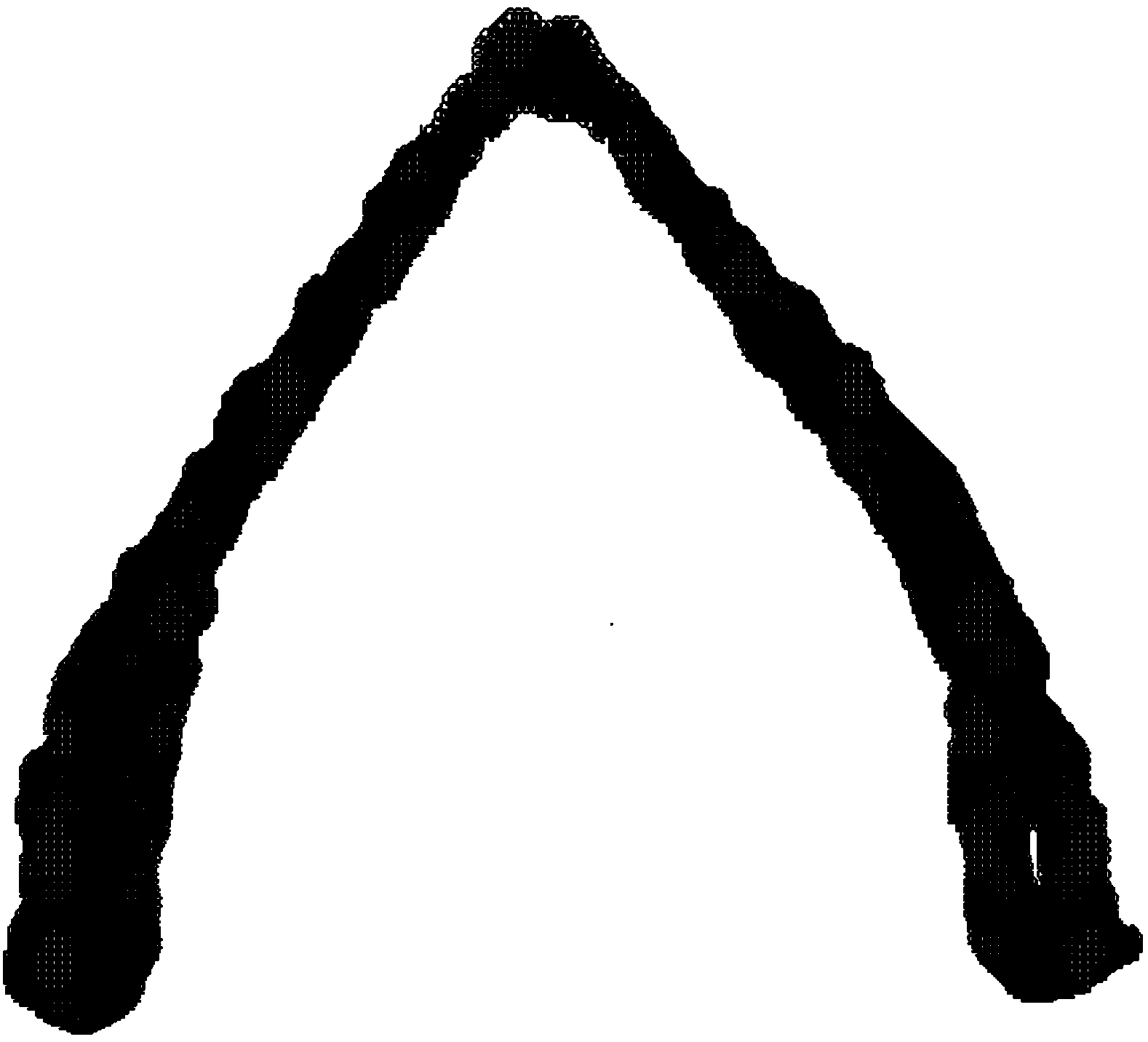

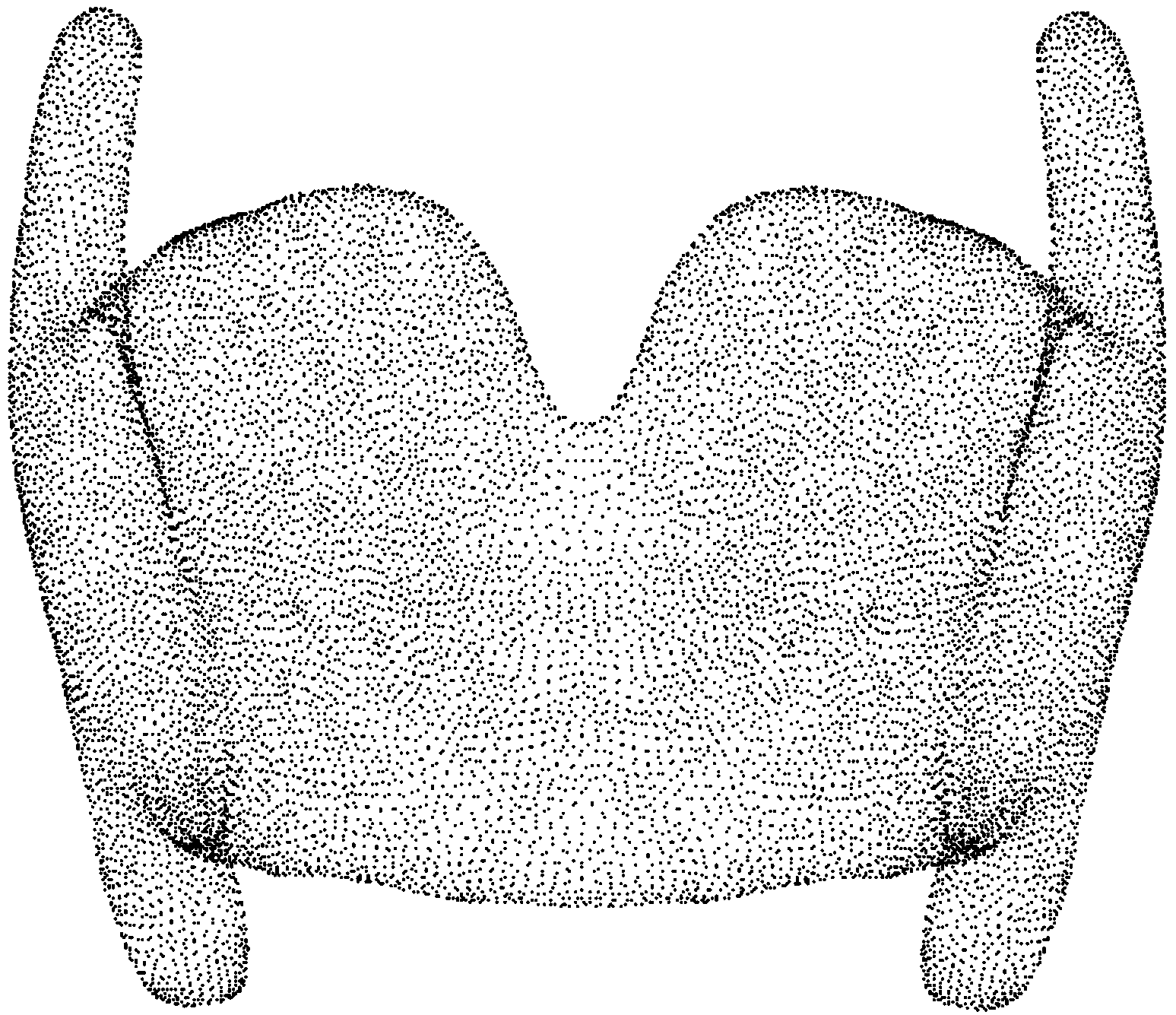

[0047] Step 1: Use high-precision medical CT to collect data from the living body, and use the segmentation algorithm to segment the thyroid cartilage area, and export the data in text format; the specific method is:

[0048] (I) Use Philips / iCT256 equipment to continuously scan the living body, the scan voltage is 120KV, the scan thickness is 0.625mm, the resolution is 1024*1024, the side length of the field of view window is 140mm, and several two-dimensional tomographic gray images in DICOM format are obtained. These image data are imported into the MIMICS software and stacked in sequence along the helical scanning axis, using the horizontal and vertical axes of the rectangular CT image as the X and Y axes, and the vertical XY plane as the Z axis to establish a spatial rectangular coordinate system;

[0049] (Ii) Using the threshold segmentation algorithm, the threshold is set to 8...

Embodiment 2

[0065] The preparation method of the personalized porous thyroid cartilage scaffold is as follows:

[0066] Step 1: Use high-precision medical CT to collect data from the living body, and use the segmentation algorithm to segment the thyroid cartilage area, and export the data in text format; the specific method is:

[0067] (I) Use Philips / iCT256 equipment to scan the living body continuously, the scan voltage is 125KV, the scan thickness is 0.675mm, the resolution is 1024*1024, the side length of the field of view window is 170mm, and several two-dimensional tomographic gray-scale images in DICOM format are obtained. These image data are imported into the MIMICS software and stacked in sequence along the helical scanning axis, using the horizontal and vertical axes of the rectangular CT image as the X and Y axes, and the vertical XY plane as the Z axis to establish a spatial rectangular coordinate system;

[0068] (Ii) Using the threshold segmentation algorithm, the threshold is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com