Catalyst for aromatization and quality modification of catalytic gasoline

A technology for catalyzing gasoline and catalysts, applied in physical/chemical process catalysts, molecular sieve catalysts, refined hydrocarbon oils, etc., can solve the problem that the stability cannot meet the needs of aromatization catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

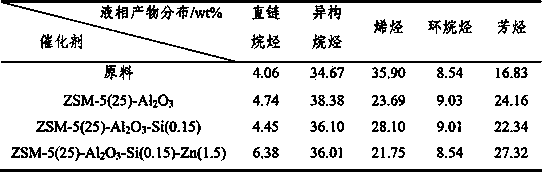

[0010] The preparation method of the catalyst of the present invention comprises the steps of placing HZSM-5 raw powder, aluminum oxide and kale powder in proportion in a container for kneading, extruding, drying, pelletizing, molding and roasting. Use n-hexane as the solvent and 20# silicone oil as the modifier to modify the outer surface of the silicon-coated catalyst. Add it dropwise to the catalyst at a solid-to-liquid volume ratio of 1.2:1. After soaking at room temperature for a period of time, evaporate the n-hexane solvent to dryness at 90°C. Afterwards, bake at 550°C for 4h. The molded catalyst is added with Zn active component by equal volume impregnation method, then dried and calcined.

[0011] Its concrete embodiment is as follows:

example 1

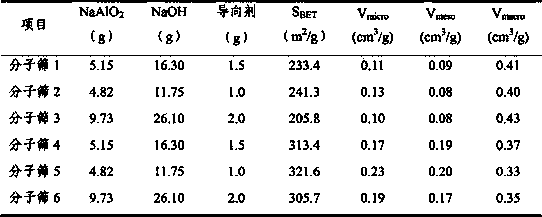

[0013] The synthesis of example one, ZSM-5 molecular sieve

[0014] According to the synthetic method of ZSM-5 molecular sieve as described in claim 4, take by weighing 100 grams of dried diatomite, measure its saturated water absorption. Dissolve the aluminum source, seed crystal directing agent and sodium hydroxide in distilled water under saturated water absorption to prepare a solution, and impregnate 100 grams of diatomaceous earth in saturation. Move the modified diatomaceous earth into a crystallization kettle and crystallize at 170°C for 24 h. After the crystallization is complete, cool to room temperature, repeat washing and filtering until the filtrate is neutral, dry at 100°C, and dry at 550°C. Roasting for 4 hours, the product molecular sieve raw powder was obtained, and the hydrogen ZSM-5 molecular sieve was obtained after ammonium nitrate exchange by the conventional method.

[0015] According to the synthetic method of ZSM-5 molecular sieve as described in clai...

example 2

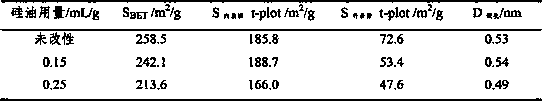

[0018] Example two, silicon-coated modification of ZSM-5 molecular sieve

[0019] With HZSM-5 raw powder, Al 2 o 3 As a binder, 60 grams of ZSM-5 powder and 40 grams of Al 2 o 3 , A small amount of extrusion aid is placed in the container for kneading, extruding, drying, dicing, molding and roasting. Get the molded carrier for later use. According to the liquid-solid volume ratio of 1.2:1, n-hexane is used as the solvent, the modifier is 20# silicone oil, and the impregnation is static at room temperature for 12 hours. The n-hexane solvent was evaporated to dryness in a water bath at 90°C, and vacuum diffusion dried at 90°C for 4 hours. Blow drying at 150°C for 2 hours, blow drying at 280°C for 2 hours, and blow drying at 550°C for 4 hours. Obtain modified molecular sieve ZSM-5(25)-Al 2 o 3 -Si(0.15) and ZSM-5(25)-Al 2 o 3 -Si(0.25), its structural parameters and physical and chemical properties are as follows:

[0020]

[0021] From the surface area and pore str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com