Ultrafiltration device for processing papermaking wastewater and application method thereof

An application method and technology for wastewater, applied in the field of water treatment, can solve the problem of waste of valuable materials, and achieve the effects of high content of useful substances, high membrane flux, and low turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

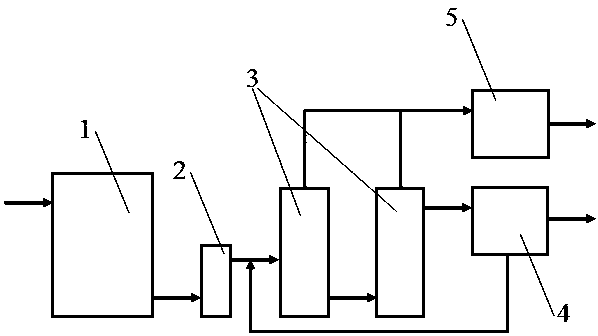

Image

Examples

Embodiment 1

[0060] The waste water in the tobacco flake manufacturing process section of a certain papermaking method is treated by the small-aperture roll-type ultrafiltration membrane of the present invention. The ultrafiltration device adopts one-stage and two-stage treatment. The water production rate of the ultrafiltration membrane is above 70%, and the treatment effect is As shown in Table 1:

[0061] Table 1 Effect of ultrafiltration treatment of papermaking wastewater

[0062] project unit System water Ultrafiltration product water Concentrate pH —— 5~6 —— —— COD mg / L 3000~6000 ≤80 ≥50000 NH 3 -N mg / L 10~150 ≤10 ≥150 SS mg / L 900~3500 ≤70 ≤70 SO 4 2- mg / L ≥100 ≤50 ≥250 Chroma times 1500~5000 ≤50 ≥5000

Embodiment 2

[0064] Tobacco flake comprehensive wastewater produced by a certain papermaking method is processed by the small-aperture roll-type ultrafiltration membrane of the present invention. The ultrafiltration device adopts one-stage one-stage treatment, and 60% of the ultrafiltration concentrated water is returned to before the ultrafiltration. The treatment effect is as follows: Table 2 shows:

[0065] Table 2 Treatment effect of papermaking wastewater by ultrafiltration

[0066] project unit System water Ultrafiltration product water Concentrate pH —— 4~6 —— —— COD mg / L ≥2300 ≤80 ≥20000 TN mg / L ≥7.2 ≤1.5 ≥20 SS mg / L ≥868 ≤30 ≤50 TP mg / L ≥3.5 ≤0.5 ≥8 Chroma times ≥244 ≤50 ≥1000

Embodiment 3

[0068] The papermaking wastewater of a certain tobacco company is processed through the papermaking wastewater ultrafiltration treatment device of the present invention and its application method, and the treatment effect is as shown in table 3:

[0069] Table 3 Treatment effect of papermaking wastewater by ultrafiltration

[0070] project unit System water Ultrafiltration product water Concentrate pH —— 6.4 —— —— COD mg / L ≥2400 ≤76 ≥20000 Conductivity μs / cm ≥771 ≤150 ≥1630 TN mg / L ≥1.5 ≤0.5 ≥5.0 Chroma times ≥100 ≤50 ≥1000

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com