Method for carrying out cooperative oxidation treatment on organic wastewater by potassium permanganate and potassium hydrogen persulfate

A technology of potassium hydrogen persulfate and organic wastewater, which is applied in the direction of oxidized water/sewage treatment, etc., to achieve the effects of reduced dosage, good decontamination effect, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

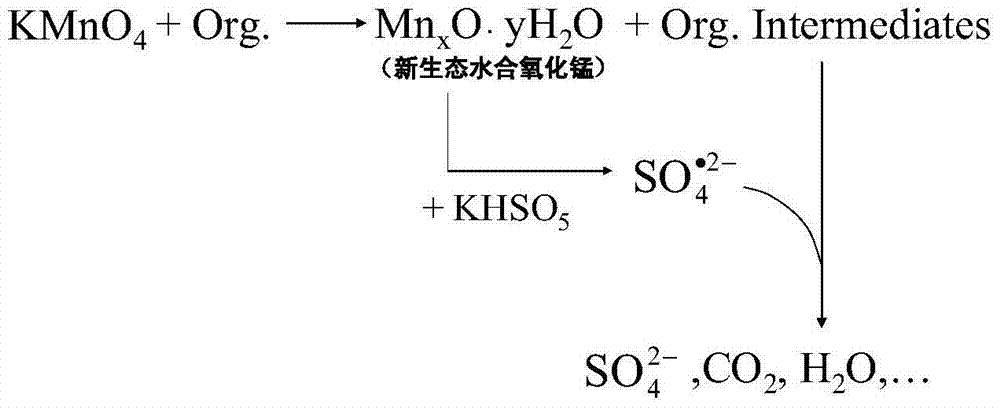

Method used

Image

Examples

Embodiment 1

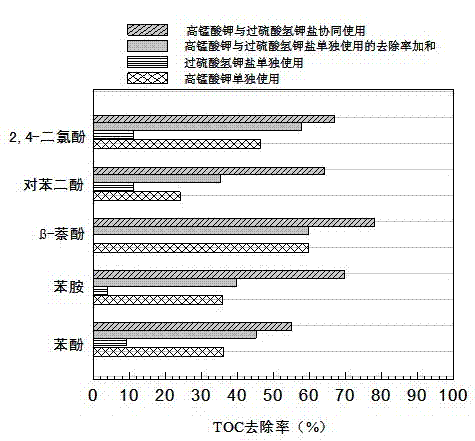

[0034] In this example, aniline organic wastewater is the object to be treated, the concentration of aniline is 100 mg / l, the corresponding total organic carbon content is 26.79 mg / L, and the pH of the wastewater is not adjusted. Both potassium permanganate and persulfate are in solution, KMnO 4The concentration of the solution is 0.25 mol / l potassium persulfate double salt (Oxone) and the concentration of the aqueous solution is 198.38 g / l. The experiments were divided into four groups, all of which used Erlenmeyer flasks with glass stoppers as reaction vessels. Experimental group 0 is a blank control without adding oxidant. Experimental group 1 used potassium permanganate alone, added 1.3 ml of 0.25 mol / l potassium permanganate solution to 100 mL of waste water, and reacted for 4 hours; the second group used potassium permanganate alone, added 198.38 1ml of potassium permanganate double salt solution of g / l was reacted for 4h; the third group of experiments combined potass...

Embodiment 2

[0038] In this example, phenol organic wastewater is the object to be treated, the phenol concentration is 100 mg / l, the corresponding total organic carbon content is 40.84 mg / L, and the wastewater is slightly acidic (pH 6). Both potassium permanganate and persulfate are in solution, KMnO 4 The concentration of the solution is 0.25 mol / l potassium persulfate double salt (Oxone) and the concentration of the aqueous solution is 198.38 g / l. The experiments were divided into four groups, all of which used Erlenmeyer flasks with glass stoppers as reaction vessels. Experimental group 0 is a blank control without adding oxidant. Experimental group 1 used potassium permanganate alone, added 2ml of 0.25mol / l potassium permanganate solution to 100mL of wastewater, and reacted for 4 hours; the second group used potassium permanganate alone, added 198.38g of potassium permanganate to 100mL of wastewater 1.55ml of potassium permanganate double salt solution per liter, reacted for 4h; the...

Embodiment 3

[0043] In this example, β-naphthol organic wastewater is the object to be treated, the concentration of naphthol is 100 mg / l, the corresponding total organic carbon content is 137.7 mg / L, and the pH of the wastewater is 8. Both potassium permanganate and persulfate are in solution, KMnO 4 The concentration of the solution is 0.25 mol / l potassium persulfate double salt (Oxone) and the concentration of the aqueous solution is 198.38 g / l. The experiments were divided into four groups, all of which used Erlenmeyer flasks with glass stoppers as reaction vessels. Experimental group 0 is a blank control without adding oxidant. Experimental group 1 used potassium permanganate alone, added 2ml of 0.25mol / l potassium permanganate solution to 100mL of wastewater, and reacted for 4 hours; the second group used potassium permanganate alone, added 198.38g of potassium permanganate to 100mL of wastewater 1.55ml perl potassium hydrogen persulfate double salt solution, reacted for 4h; the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com