Novel solidified dielectric material suitable for simultaneously lattice solidifying actinium nuclide and fission product 90Sr as well as preparation method thereof

A technology of dielectric materials and fission products, which is applied in the field of new solidified dielectric materials and its preparation, can solve the problems of restricting the popularization and application of nuclear waste treatment, the difficulty and complexity of the treatment process, and the difficulty of obtaining pure phase materials, so as to avoid multiple separations/ The effect of sorting solidification, simple treatment process, and minimization of waste volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

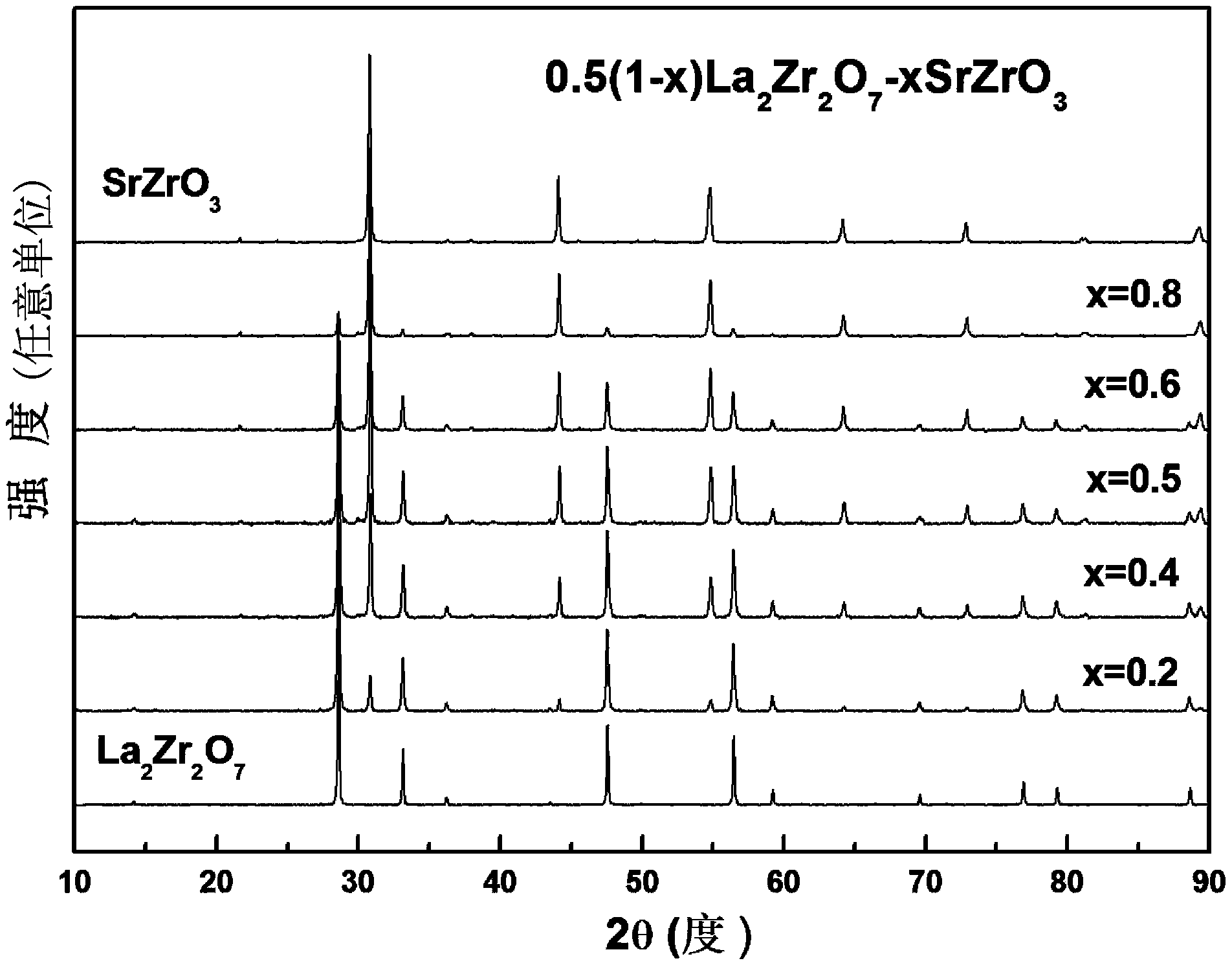

[0048] Example 1 : Made 0.5(1-x) La 2 Zr 2 o 7 -xSrZrO 3 (0.2≤x≤0.8) Composite curing medium material

[0049] With a purity of 99.99% La(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·3H 2 O and Sr(NO 3 ) 2 As a raw material, prepare a standard aqueous solution with a concentration of 0.1mol / L. Using a precision of 10 -4 g's electronic balance accurately weighs the required raw materials, puts them into a 1L glass beaker filled with 500ml of ultrapure water and stirs them magnetically, pours them into a 1L standard volumetric flask after completely dissolving, and then rinses the beaker with 100ml of ultrapure water Then pour it into a standard volumetric flask, repeat this 4 times, and finally use a burette with an accuracy of 0.1ml to drop ultrapure water until the scale of the standard volumetric flask is ready for use.

[0050] Using a burette with a capacity of 25ml and an accuracy of 0.1ml, the molar ratio of LaO 1.5 :SrO:ZrO 2 =(1-x):x:1 (x=0.2, 0.4, 0.5, 0.6, 0.8) is...

Embodiment 2

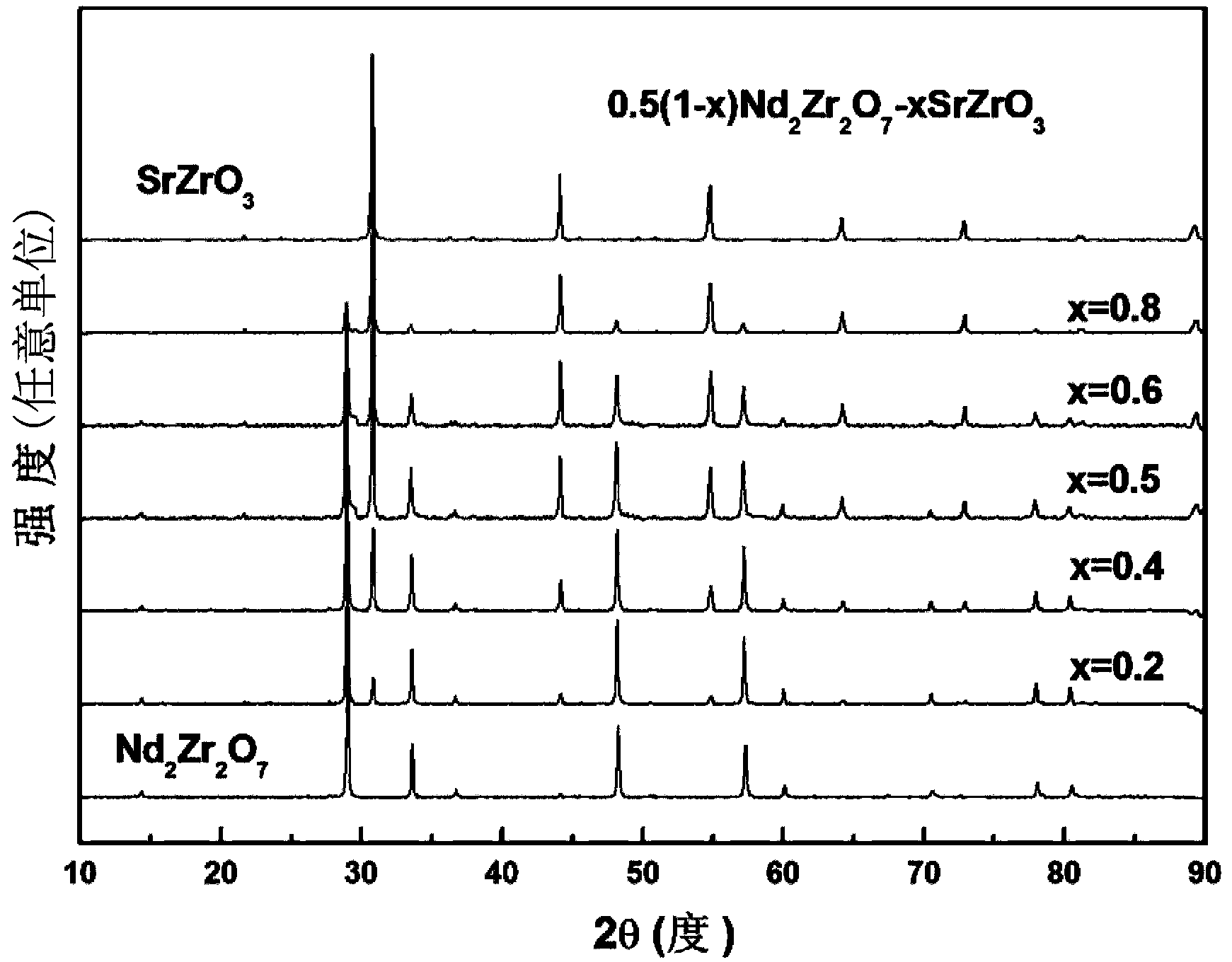

[0054] Example 2 : Made 0.5(1-x)Nd 2 Zr 2 o 7 -xSrZrO 3 (0.2≤x≤0.8) Composite curing medium material

[0055] With a purity of 99.99% Nd(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·3H 2 O and Sr(NO 3 ) 2 As a raw material, prepare a standard aqueous solution with a concentration of 0.1mol / L. Using a precision of 10 -4 g's electronic balance accurately weighs the required raw materials, puts them into a 1L glass beaker filled with 500ml of ultrapure water and stirs them magnetically, pours them into a 1L standard volumetric flask after completely dissolving, and then rinses the beaker with 100ml of ultrapure water Then pour it into a standard volumetric flask, repeat this 4 times, and finally use a burette with an accuracy of 0.1ml to drop ultrapure water until the scale of the standard volumetric flask is ready for use.

[0056] Using a burette with a capacity of 25ml and an accuracy of 0.1ml, the NdO 1.5 :SrO:ZrO 2 =(1-x):x:1 (x=0.2, 0.4, 0.5, 0.6, 0.8) is accurately weig...

Embodiment 3

[0062] Example 3 : Made 0.5(1-x)Eu 2 Zr 2 o 7 -xSrZrO 3 (0.2≤x≤0.8) Composite curing medium material

[0063] With a purity of 99.99% Eu(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·3H 2 O and Sr(NO 3 ) 2 As a raw material, prepare a standard aqueous solution with a concentration of 0.1mol / L. Using a precision of 10 -4 g's electronic balance accurately weighs the required raw materials, puts them into a 1L glass beaker filled with 500ml of ultrapure water and stirs them magnetically, pours them into a 1L standard volumetric flask after completely dissolving, and then rinses the beaker with 100ml of ultrapure water Then pour it into a standard volumetric flask, repeat this 4 times, and finally use a burette with an accuracy of 0.1ml to drop ultrapure water until the scale of the standard volumetric flask is ready for use.

[0064] A burette with a capacity of 25ml and an accuracy of 0.1ml is used, and the molar ratio of EuO 1.5 :SrO:ZrO 2 =(1-x):x:1 (x=0.2, 0.4, 0.5, 0.6, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com