Caustic sludge treatment method

A treatment method and technology for alkali residues, which are applied in the directions of inorganic fertilizers, potash fertilizers, fertilization devices, etc., can solve the problems of environmental pollution caused by the stacking of alkali residues, and achieve the effects of easy operation, low cost of raw materials, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

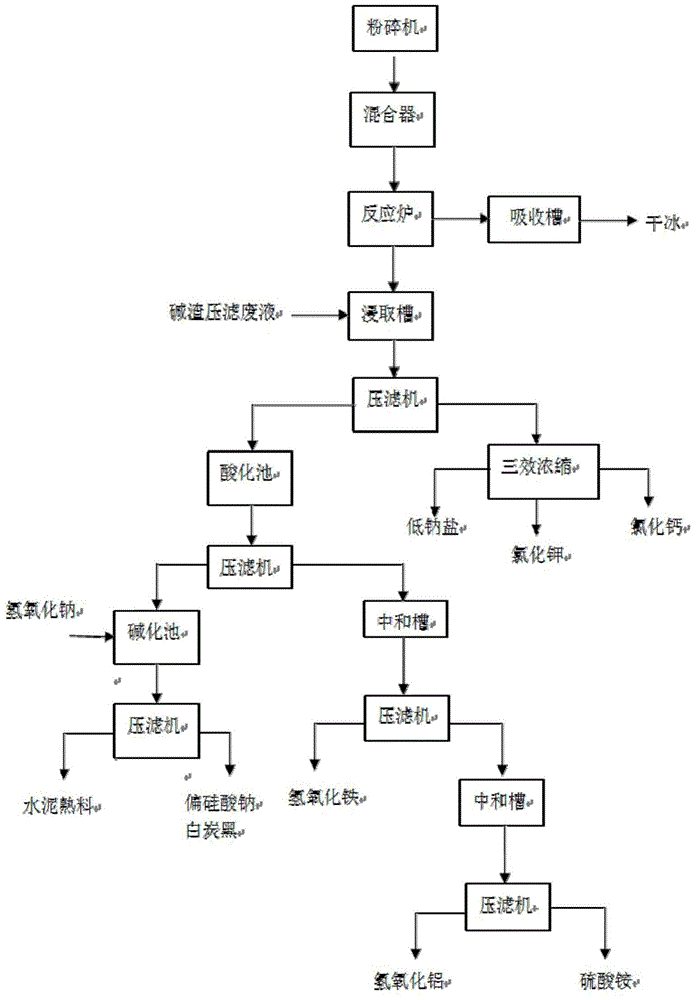

Image

Examples

Embodiment 1

[0047] Step 1: Mix potassium feldspar, alkali slag and salt mud evenly in a weight ratio of 1:1.5:0.2, and pulverize them to 100 mesh in a ball mill;

[0048] Step 2: Put the uniformly mixed potassium feldspar, alkali slag and salt mud into the suspension preheating furnace for roasting, sintering at 1200°C for 1 hour, take it out, add water to dissolve the sintered material and boil for 10 minutes, centrifuge to separate the precipitate Afterwards, the supernatant was concentrated to obtain low-sodium salt, potassium chloride, and calcium chloride respectively;

[0049]Step 3: After the separated residue is treated with acid, the pH of the separated liquid is adjusted so that the pH is 7 to 8, and then separated by pressure filtration in a plate and frame filter press to obtain ferric hydroxide and aluminum hydroxide respectively; insoluble Add 20%-35% sodium hydroxide to the reaction kettle to adjust to strong alkalinity, boil and dissolve, and keep strong alkalinity all the...

Embodiment 2

[0051] Step 1: Mix potassium feldspar, alkali slag and salt mud evenly in a weight ratio of 1:1:0.5, and pulverize them to 100 mesh in a ball mill;

[0052] Step 2: Put the uniformly mixed potassium feldspar, alkali slag and salt mud into the suspension preheating furnace for roasting, sintering at 1000°C for 1.5 hours, take it out, add water to dissolve the sintered material and boil for 30 minutes, centrifuge to separate the precipitate Afterwards, the supernatant was concentrated to obtain low-sodium salt, potassium chloride, and calcium chloride respectively;

[0053] Step 3: After the separated residue is treated with acid, the separated liquid is prepared by adjusting the pH to obtain ferric hydroxide and aluminum hydroxide; the insoluble residue is added to the reaction kettle to adjust the pH to maintain strong alkalinity, and boil to dissolve. And keep strong alkalinity all the time, the mixture obtained after half an hour is centrifuged, the separated precipitate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com