Method and device for producing benzyl benzoate

A technology of benzyl benzoate and benzoic acid, which is applied in the field of benzyl benzoate production, can solve problems such as benzyl benzoate that cannot be solved, and achieve the effects of improving economic benefits, reducing waste of resources, and simple device flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

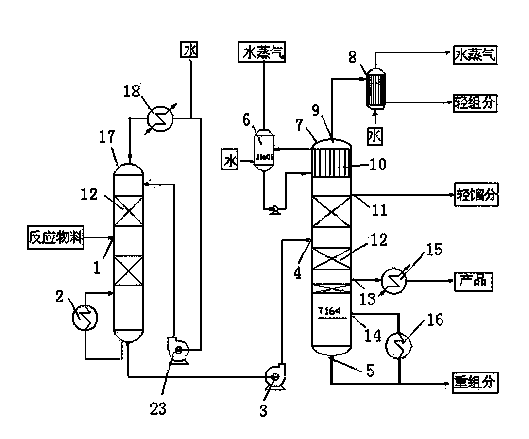

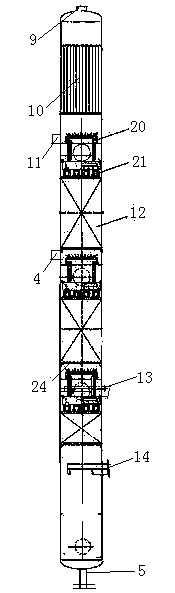

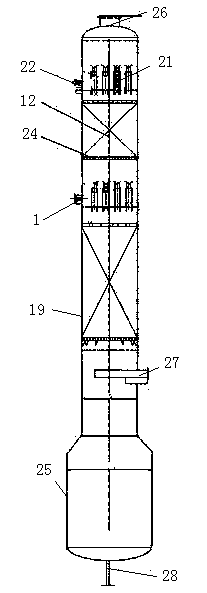

[0017] The present invention produces the device of benzyl benzoate, as figure 1 As shown, including reactive distillation column 17, cooler 18, reboiler 2, reflux pump 23, rectification column 7, steam drum 6, external condenser 8, product cooler 15, reboiler 16 and feed pump 3. Such as figure 2 As shown, the rectification tower is provided with a rectification tower inlet 4 , a tower top gas outlet 9 , a light fraction outlet 11 , a product outlet 13 , a recycle inlet 14 and a heavy component outlet 5 . There are three packing layers 12 in the rectification tower, the packing of the packing layers is 500Y structured packing, and the packing support 24 is arranged at the lower part of the packing. The rectification column is provided with a liquid collector 20 and a liquid distributor 21 , the liquid collector is located on the upper part of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com