A kind of method for preparing acipimox

A technology of sodium tungstate and hydrogen peroxide, which is applied in the field of preparation of acipimox, can solve the problems of unsuitability for industrial production, high cost of raw materials, and long synthetic route, and achieve the effects of low cost, convenient operation, and short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

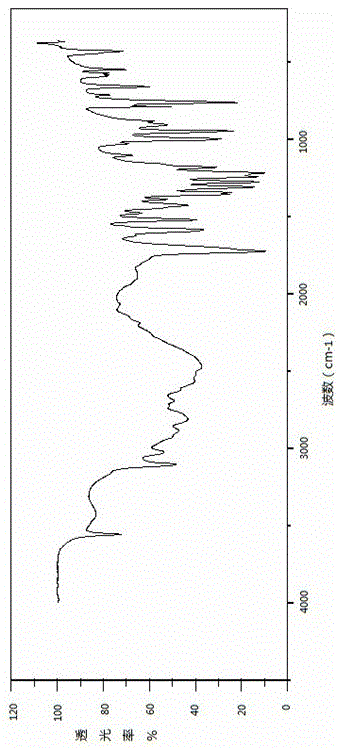

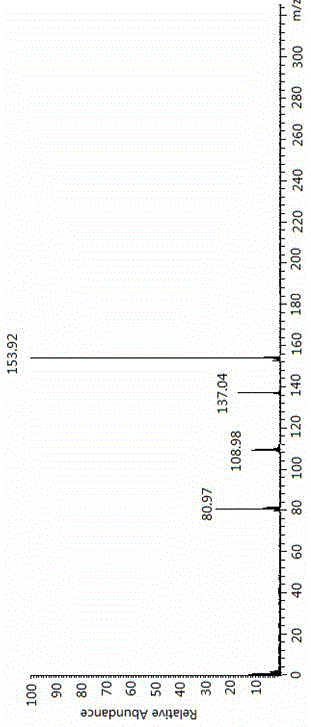

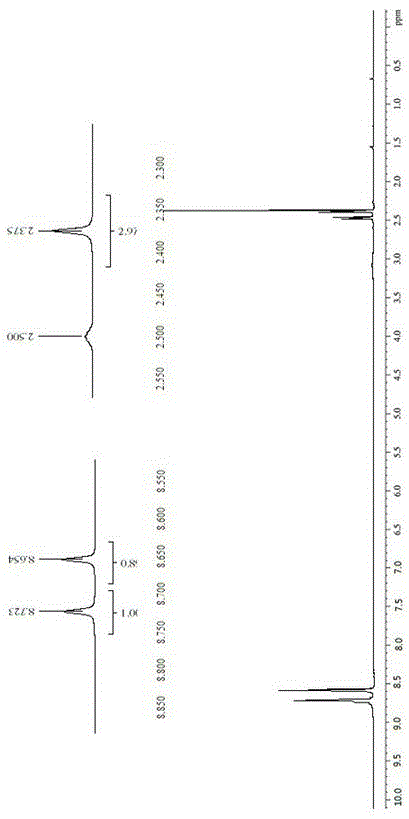

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of method for preparing acipimox, this method comprises the following steps:

[0030] Add 2730ml of concentrated sulfuric acid with a mass concentration of 98% into a 10L glass reactor, add 910.0g of 5-methylpyrazine-2,3-dicarboxylic acid under stirring conditions, heat to 60°C, heat the reaction for 1h, then slowly Add 5.5kg of water, 164.9g of sodium tungstate (Na 2 WO 4 2H 2 O), 623.0g of hydrogen peroxide with a mass concentration of 30%, continued heating and stirring for 8h, cooled and crystallized in an ice bath for 4h, filtered the solid with suction, dried at 100°C for 12h, and prepared 708.0g of the product acipimox. The product yield in this reaction was 92%; the HPLC purity was greater than 99% (area normalization method).

Embodiment 2

[0031] Embodiment 2: the method for preparing acipimox, the method comprises the following steps:

[0032] Add 5.5kg of water into a 10L glass reactor, slowly add 27ml of concentrated sulfuric acid with a mass concentration of 98% under stirring conditions, then add 910.0g of 5-methylpyrazine-2,3-dicarboxylic acid, and heat at 60°C for 1 hour , and then add 164.9g sodium tungstate (Na 2 WO 4 2H 2 O), 623.0g of hydrogen peroxide with a mass concentration of 30%, continued heating and stirring for 8h, cooled and crystallized in an ice bath for 4h, filtered the solid with suction, dried at 100°C for 12h, and prepared 693.5g of the product acipimox. The product yield in this reaction is 90%; the HPLC purity is greater than 99% (area normalization method).

Embodiment 3

[0033] Embodiment 3: the method for preparing acipimox, the method comprises the following steps:

[0034] Add 2000ml of concentrated hydrochloric acid with a mass concentration of 36% into a 10L glass reactor, then add 910.0g of 5-methylpyrazine-2,3-dicarboxylic acid, heat the reaction at 70°C for 1.5h, then slowly add 5.5kg of water, Then add 82.5g sodium tungstate (Na 2 WO 4 2H 2 O), 680.0 g of hydrogen peroxide with a mass concentration of 30%, continued heating and stirring for 10 h, cooled and crystallized in an ice bath for 4 h, filtered the solid with suction, dried at 100°C for 12 h, and prepared 678.1 g of the product acipimox. The product yield in this reaction was 88%; the HPLC purity was greater than 98% (area normalization method).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com