Method for preparing nanometer-micrometer multi-scale fiber prepreg

A multi-scale, prepreg technology, applied in the field of nano-micron multi-scale fiber prepreg preparation, achieves the effects of high production efficiency, rich varieties and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment relates to a preparation method of nano-micron multi-scale fiber prepreg, and the method includes the following steps:

[0034] Step 1: Purify 2g of multi-walled carbon nanotubes (MWCNT) with a mixture of 80ml concentrated sulfuric acid (98%) and concentrated nitric acid (65%) (volume ratio 3:1), purify and functionalize the surface Rich in oxygen-containing functional groups;

[0035] Step 2: Mix 1 part of multi-walled carbon nanotubes (MWCNT) and 100 parts of diglycidyl ether epoxy resin with ultrasonic-assisted mechanical stirring, the power of ultrasonic wave is 100W, the treatment time is 2h, heated at 80°C, and 40 parts of The amine curing agent is continuously stirred to uniformity under the assistance of vacuum to form an epoxy resin system modified by carbon nanotube material;

[0036] Step 3: The resin system modified by carbon nanomaterials is prepared by a coating device with a width of 1000mm and an areal density of 100g / m 2 , a carbon nan...

Embodiment 2

[0040] This embodiment relates to a preparation method of nano-micron multi-scale fiber prepreg, and the method includes the following steps:

[0041] Step 1: Purify 1 g of graphene (Graphene) with a mixture of 80 ml concentrated sulfuric acid (98%) and concentrated nitric acid (65%) (volume ratio 3:1), purify and functionalize it, and make its surface rich in oxygen functional group;

[0042]Step 2: 5 parts of graphene (Graphene) and 100 parts of diamine modified BMI resin are mixed with ultrasonic-assisted mechanical stirring, the ultrasonic power is 100W, the treatment time is 2h, heated at 80°C, and 40 parts of acid anhydrides are added to cure agent, and continue to stir until uniform under vacuum assistance to form a graphene-modified resin system;

[0043] Step 3: The graphene-modified resin system is prepared with a film coating device with a width of 600 mm and an areal density of 10 g / m 2 , a graphene-modified resin film with a viscosity of 0.1 Pa s;

[0044] Step...

Embodiment 3

[0047] This embodiment relates to a preparation method of nano-micron multi-scale fiber prepreg, and the method includes the following steps:

[0048] Step 1: Add 2g of carbon nanofibers to a mixture of 80ml of concentrated sulfuric acid (98%) and concentrated nitric acid (65%) (volume ratio 3:1), after ultrasonic dispersion for 2h, stir at 120°C for 60min, use up Washed with ionized water until neutral, dried to obtain surface carboxylated carbon nanofibers:, then added to N,N`-dimethylformamide (DMF) solution containing 50% ethylenediamine, heated and stirred at 80 °C for 6 h, After washing with deionized water and drying, the aminated carbon nanofibers were obtained.

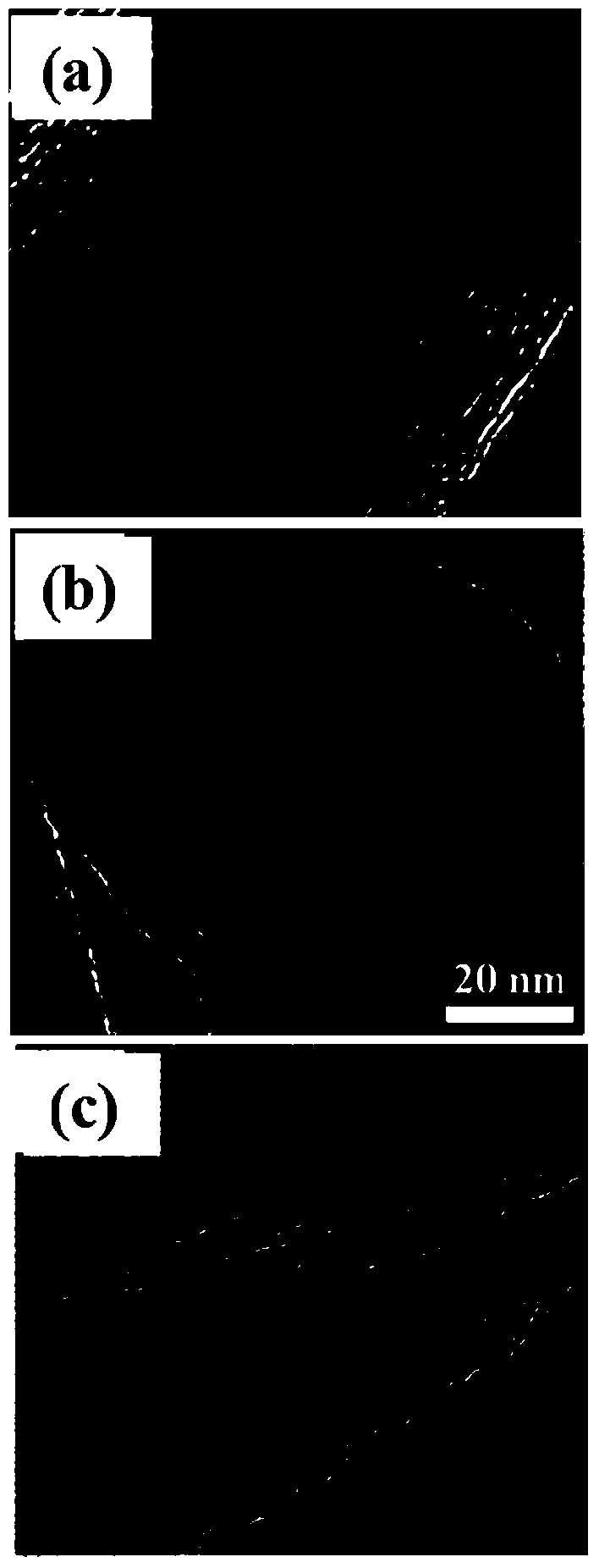

[0049] Implementation effect: see the nano-micron multi-scale fiber prepreg prepared in this example. figure 1 Middle (b) SEM image of carbon nanofibers, which not only improves the properties of the resin itself, but also enhances the interfacial properties between the fibers and the resin, and realizes the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com