Engine cooling liquid prepared by utilizing coal ethylene glycol waste

An engine coolant, coal-to-ethylene glycol technology, applied in the field of engine coolant, can solve problems such as waste of resources, and achieve the effects of reducing corrosion, lowering freezing point, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

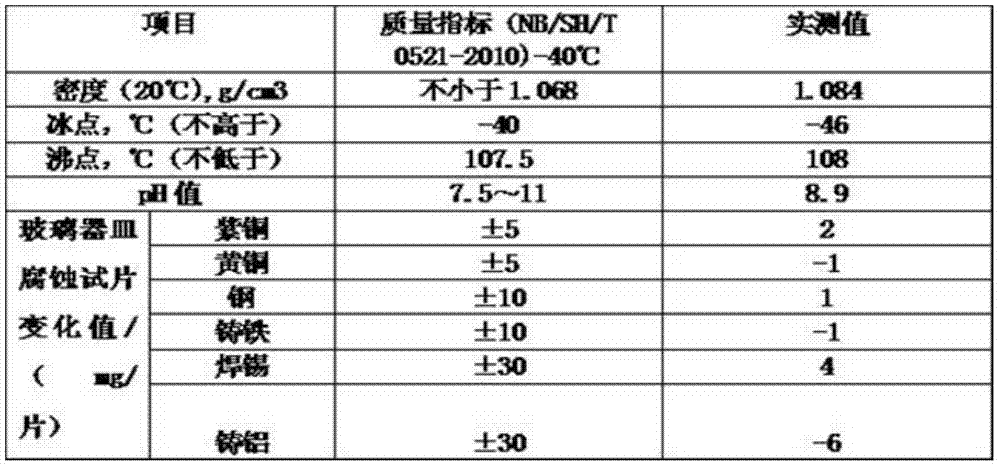

Image

Examples

Embodiment 1

[0017] Example 1: Add 0.097 parts of polyacrylate into 30 parts of deionized water, stir evenly to dissolve. Then add 68 parts of effective antifreeze components in coal-based ethylene glycol waste, 0.8 parts of sodium nitrite, 0.2 parts of sodium molybdate, 0.6 parts of disodium hydrogen phosphate, 0.3 parts of methacrylate and 0.003 parts of methylene blue, at 40 °C Stir to dissolve completely.

[0018] The effective antifreeze component in the ethylene glycol waste is the distillate of coal-based ethylene glycol waste at 110°C to 260°C.

Embodiment 2

[0019] Example 2: 0.097 parts of polymethacrylic acid hydroxyethylidene diphosphonic acid was added to 35 parts of deionized water, stirred evenly to dissolve. Then add 62 parts of effective antifreeze components in coal-based ethylene glycol waste, 1 part of sodium nitrite, 1 part of sebacic acid, 0.8 part of disodium hydrogen phosphate, 0.1 part of polyether defoamer and 0.003 part of methylene blue , Stir at 40°C to dissolve completely.

[0020] The effective antifreeze component in the ethylene glycol waste is the distillate of coal-based ethylene glycol waste at 105°C to 200°C.

Embodiment 3

[0021] Example 3: 0.1 part of polyacrylate and 0.098 part of sodium ethylenediamine tetramethylene phosphonate were added to 40 parts of deionized water, stirred evenly to dissolve. Then add 58 parts of effective antifreeze components in coal-based ethylene glycol waste, 1 part of sodium nitrite, 0.3 parts of sodium molybdate, 0.2 parts of sodium borate, 0.3 parts of methacrylate and 0.002 parts of methyl red, at 40 ° C Stir to dissolve completely.

[0022] The effective antifreeze component in the ethylene glycol waste is the distillate of coal-based ethylene glycol waste at 100°C to 260°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com