Coal tar and coal water slurry mixed fuel and preparation method thereof

A technology of mixed fuel and coal water slurry, which is applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of coal tar pollution, strong smell of coal tar, waste of resources, etc., and reduce the waste of coke oven gas venting and burning Resources, low viscosity of finished products, complete combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

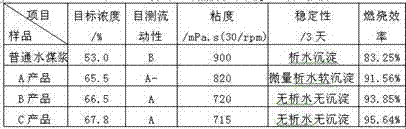

Examples

Embodiment 1

[0037] A kind of coal tar coal-water slurry mixed fuel of the present invention is made up of the raw material of following weight portion:

[0038] 55 parts of superfine pulverized coal;

[0039] 10 parts of coal tar;

[0040] 10 parts of water;

[0041] Sodium petroleum sulfonate 2 parts;

[0042] 3 parts sodium naphthenate;

[0043] Sodium lignosulfonate 1 part;

[0044] Sodium Polypropylene Sulfonate 2 parts

[0045] 2 parts of polyoxyethylene lauryl ether;

[0046] 2 parts of phenylethylphenol polyoxypropylene polyoxyethylene ether;

[0047] 2 parts of bisphenylethylphenol polyoxyethylene ether;

[0048] Glycerin polyoxyethylene ether polyoxypropylene ether fatty acid ester 1 part.

[0049] Its preparation process is as follows:

[0050] (1), preparation of coal-water slurry: Put the pulverized raw coal into a ball mill, take it out after grinding for 1 hour, pass through a 180-mesh sieve to obtain superfine coal powder, mix 55 parts of superfine coal powder with...

Embodiment 2

[0053] A kind of coal tar coal-water slurry mixed fuel of the present invention is made up of the raw material of following weight portion:

[0054] 60 parts of superfine pulverized coal;

[0055] 18 parts of coal tar;

[0056] 12 parts of water;

[0057] Sodium petroleum sulfonate 2 parts;

[0058]Sodium naphthenate 1 part;

[0059] Sodium Polypropylene Sulfonate 1 part;

[0060] 2 parts of polyoxyethylene lauryl ether;

[0061] 2 parts of bisphenylethylphenol polyoxyethylene ether;

[0062] Glycerin polyoxyethylene ether polyoxypropylene ether fatty acid ester 2 parts.

[0063] Its preparation process is as follows:

[0064] (1) Preparation of coal-water slurry: Put the pulverized raw coal into a ball mill, grind it for 1.5 hours, take it out, and pass through a 220-mesh sieve to obtain ultra-fine coal powder. Mix 60 parts of ultra-fine coal powder with 12 parts of water, and then add 2 parts of petroleum sodium sulfonate and 1 part of sodium naphthenate, after stirr...

Embodiment 3

[0067] A kind of coal tar coal-water slurry mixed fuel of the present invention is made up of the raw material of following weight portion:

[0068] 60 parts of superfine pulverized coal;

[0069] 20 parts of coal tar;

[0070] 20 parts of water;

[0071] Sodium petroleum sulfonate 2 parts;

[0072] Sodium naphthenate 1 part;

[0073] Sodium lignosulfonate 1 part;

[0074] 2 parts of polyoxyethylene lauryl ether;

[0075] 2 parts of phenylethylphenol polyoxypropylene polyoxyethylene ether;

[0076] Glycerin polyoxyethylene ether polyoxypropylene ether fatty acid ester 2 parts.

[0077] Its preparation process is as follows:

[0078] (1), preparation of coal-water slurry: put the pulverized raw coal into a ball mill, grind for 1.5 hours, take it out, and pass through a 220-mesh sieve to obtain superfine coal powder. Mix 60 parts of superfine coal powder with 20 parts of water, add 2 parts of sodium petroleum sulfonate and 1 part of sodium naphthenate, and stir with a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com