A metering method using a laboratory trace gas metering device

A technology of trace gas and metering devices, which is applied in the direction of measuring devices, volume measuring instruments/methods, and measuring capacity, etc. It can solve the problems of affecting the experimental accuracy, large instrument range, and batch use, etc., and achieves low cost, strong applicability, and easy production. The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

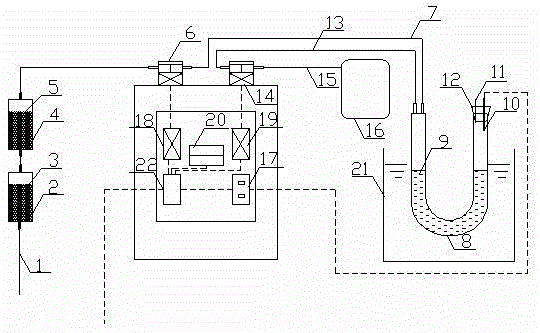

[0027] A laboratory trace gas metering device, such as figure 1 As shown, it is composed of a gas purification unit, a metering collection unit and a control unit. The gas purification unit includes an inlet pipe 1, a drying column 2, a desulfurization column 4, and an intake solenoid valve 6, which are connected in series through pipelines. The drying column 2 and the desulfurization column 4 are connected in series. Both are plexiglass round tubes, with an air inlet and an air outlet at the bottom and top respectively, the drying column 2 is filled with a desiccant 3, and the desulfurization column 4 is filled with a desulfurizing agent 5; the metering and collecting unit includes a U-shaped metering tube 8, constant temperature water Bath 21, gas outlet solenoid valve 14, gas outlet solenoid valve outlet pipe 15 and gas collection bag 16, one end of U-shaped metering pipe 8 is respectively provided with U-shaped metering pipe inlet pipe 7 and U-shaped metering pipe outlet p...

Embodiment 2

[0035] A laboratory trace gas metering device, which is basically the same as that of Embodiment 1, the differences are as follows.

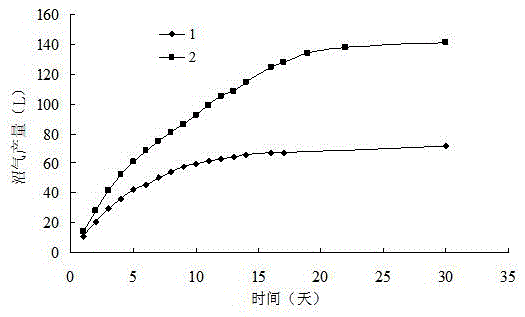

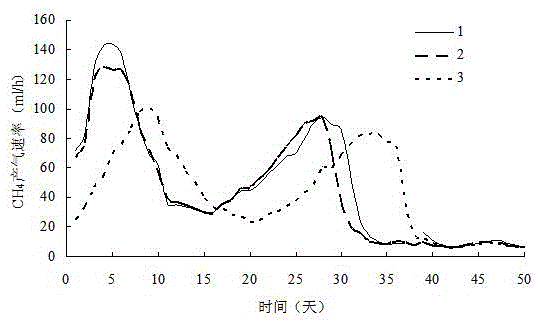

[0036]The device measures the amount of methane gas accumulated in the 5L anaerobic digestion reactor during the anaerobic digestion process of agricultural waste and draws the methane production rate curve. The desiccant is silica gel, the desulfurizer is granular activated carbon, and the metering liquid is 4mol / L% The NaOH solution, implementation method is as follows:

[0037] 1) Operation process: The biogas produced by the experimental reactor passes through the drying device 2 filled with calcium sulfate and the desulfurization device 4 filled with iron oxide to remove water vapor and hydrogen sulfide in the gas. At this time, the electric intake valve 6 is opened, and the solenoid valve 14 is closed. The purified gas enters the U-shaped metering tube 8 with a working scale of 25ml and filled with 4mol / L NaOH solution through the inlet el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com