Sample introduction device for improving detection sensitivity of ion mobility spectrometry (IMS)

A technology of detection sensitivity and ion mobility spectrometry, which is applied in the field of thermal analysis sampling device, can solve the problems of difficult quantitative detection, unstable sample gas flow, overheating decomposition, etc., to improve detection sensitivity, improve sample injection efficiency, and fast temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

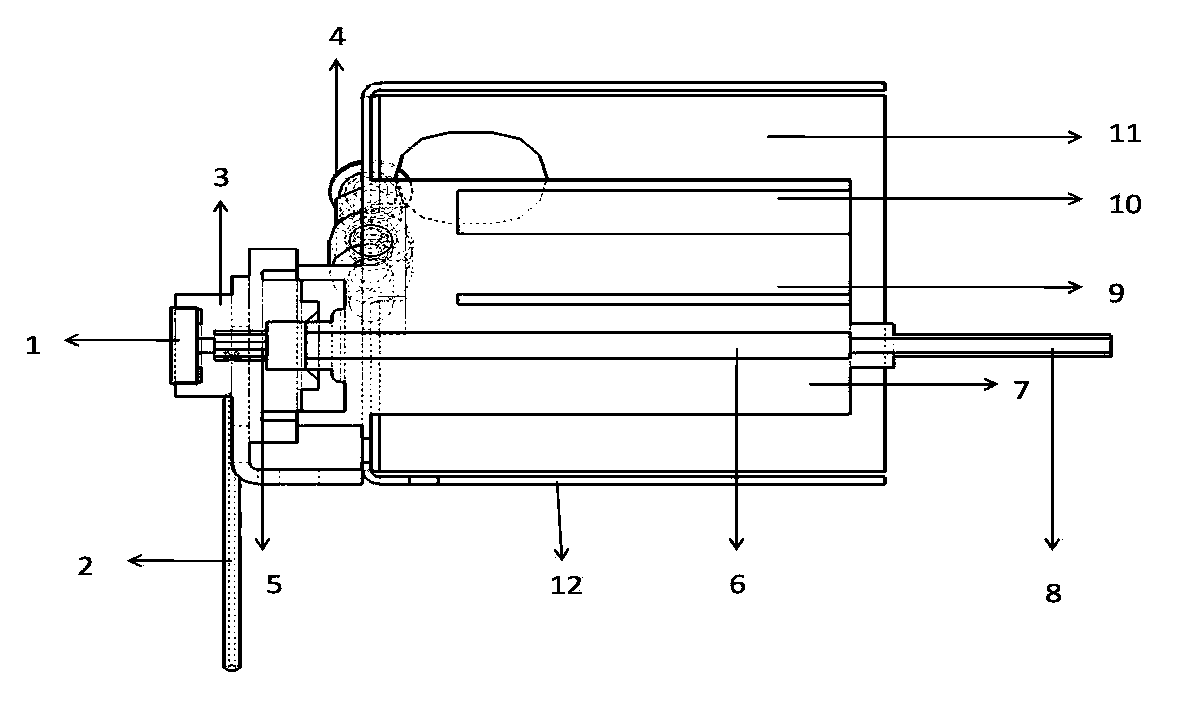

[0031] figure 1 Schematic diagram of the device for the ion mobility spectrometry thermal desorption sampler designed in the invention, in which (1) injection septum, (2) purge gas outlet, (3) septum purge chamber, (4) total gas flow Inlet, (5) Connecting nut, (6) Thermal desorption chamber, (7) Thermal desorption chamber heating module, (8) Connecting pipe connecting the sample injector to the ion mobility tube of the ion mobility spectrometer, (9) Temperature sensor , (10) heating rod, (11) insulating cotton layer, (12) wrapping the outer packaging shell of the sampler.

[0032] Accurately measure 1-50μL, 1ppt-100ppm different sample solutions with a micro-sampling needle. The sample to be tested is sampled through a manual injection needle with an injection volume of 1-20 μL, and the needle is directly inserted into the liner through the central concave hole of the injection septum (1). The sample injected into the liner is instantly vaporized at the set higher temperature....

Embodiment 2

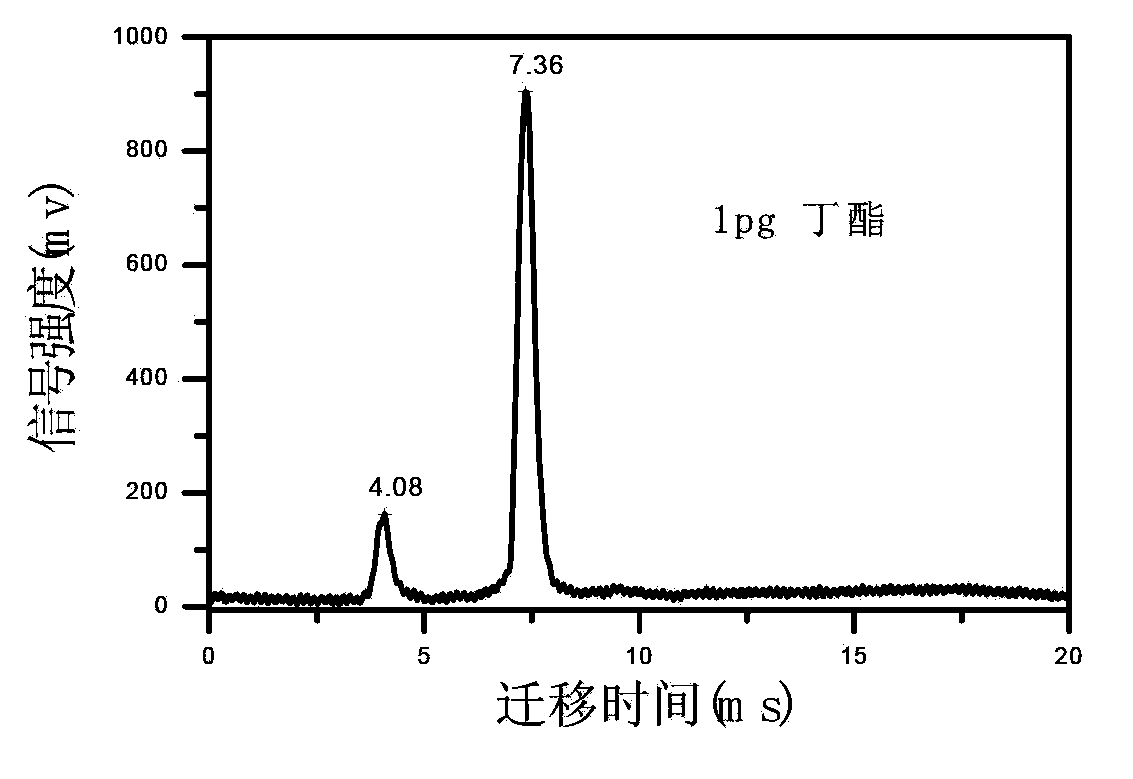

[0035] figure 2 In the positive ion mode, this sampler is used to detect the ion mobility spectrum of 1pg dibutyl phthalate; use a micro-syringe to accurately measure 1μL of dibutyl phthalate solution with a concentration of 1ppb, that is, 1pg sample. In the positive ion mode, the ion mobility spectrometer was used as the detection instrument, and the sample was injected manually. In the positive ion mode, the air reagent ion peak (RIP) appears at about 4.08ms. The peak migration time of dibutyl phthalate is about 7.36ms. The signal is so strong that it nearly masks the air reagent ion peak.

[0036] Compared with the solenoid valve injector designed and developed before, 1pg is almost the detection limit of those instruments. It can be seen that this specially designed thermal desorption sampler is very sensitive for testing dibutyl phthalate.

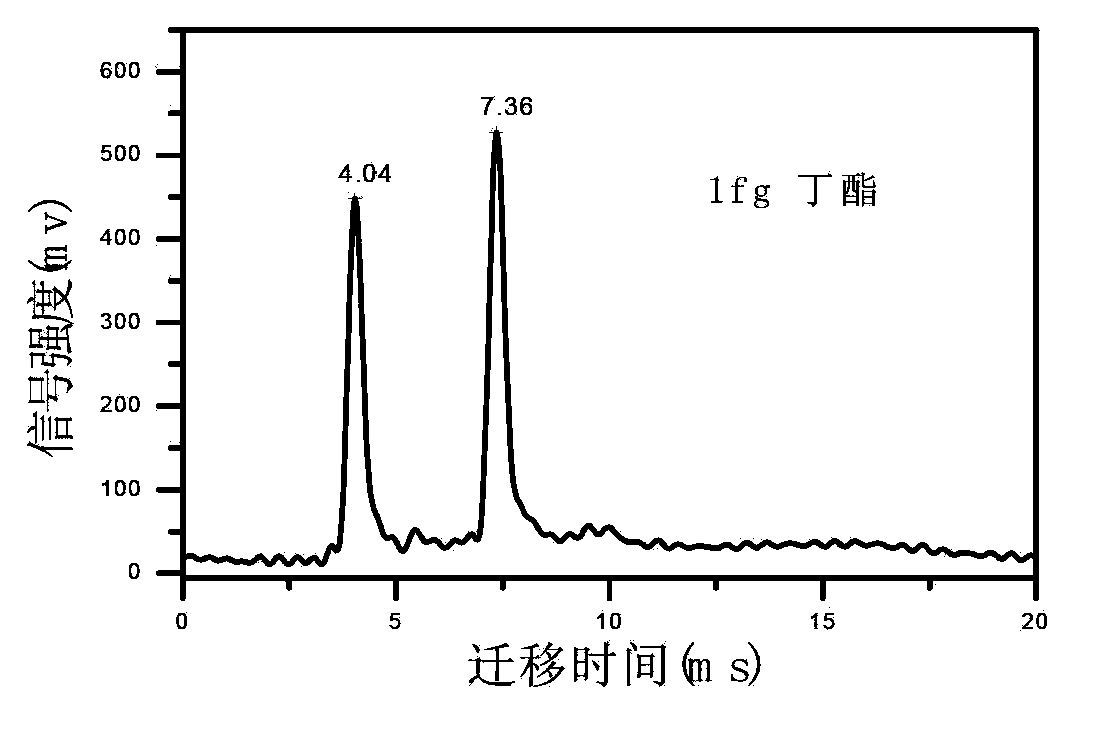

[0037] In the same way, image 3 In the positive ion mode, this sampler is used to detect the ion mobility spectrum of 1fg di...

Embodiment 3

[0040] Figure 4 It is ion mobility spectrometry in negative ion mode, and the ion mobility spectrogram of 1ng TNT detected by a solenoid valve injector; accurately measure 1 μL of TNT solution with a concentration of 1ppm with a micro-syringe needle, that is, 1ng sample. In the negative ion mode, the ion mobility spectrometer was used as the detection instrument, and the sample was injected manually. In the negative ion mode, the air reagent ion peak (RIP) appears at about 6.12ms, and the signal strength is 400mv. The peak migration time of TNT is 9.02ms, and the signal strength is about 180mv. The TNT signal was weaker than the RIP signal, and the ratio of the two signals was 0.45.

[0041] Figure 5 Ion mobility spectrometry in negative ion mode, the thermal desorption sampler designed in the invention detects the ion mobility spectrogram of 1ngTNT; accurately measure 1μL of TNT solution with a concentration of 1ppm with a micro-injection needle, that is, 1ng sample. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com