Optimizing method of reaction model for preparing ethylene molecules through naphtha high-temperature steam cracking

A technology for producing ethylene and high-temperature steam by cracking, which can be used in special data processing applications, instruments, calculations, etc., and can solve problems such as poor adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

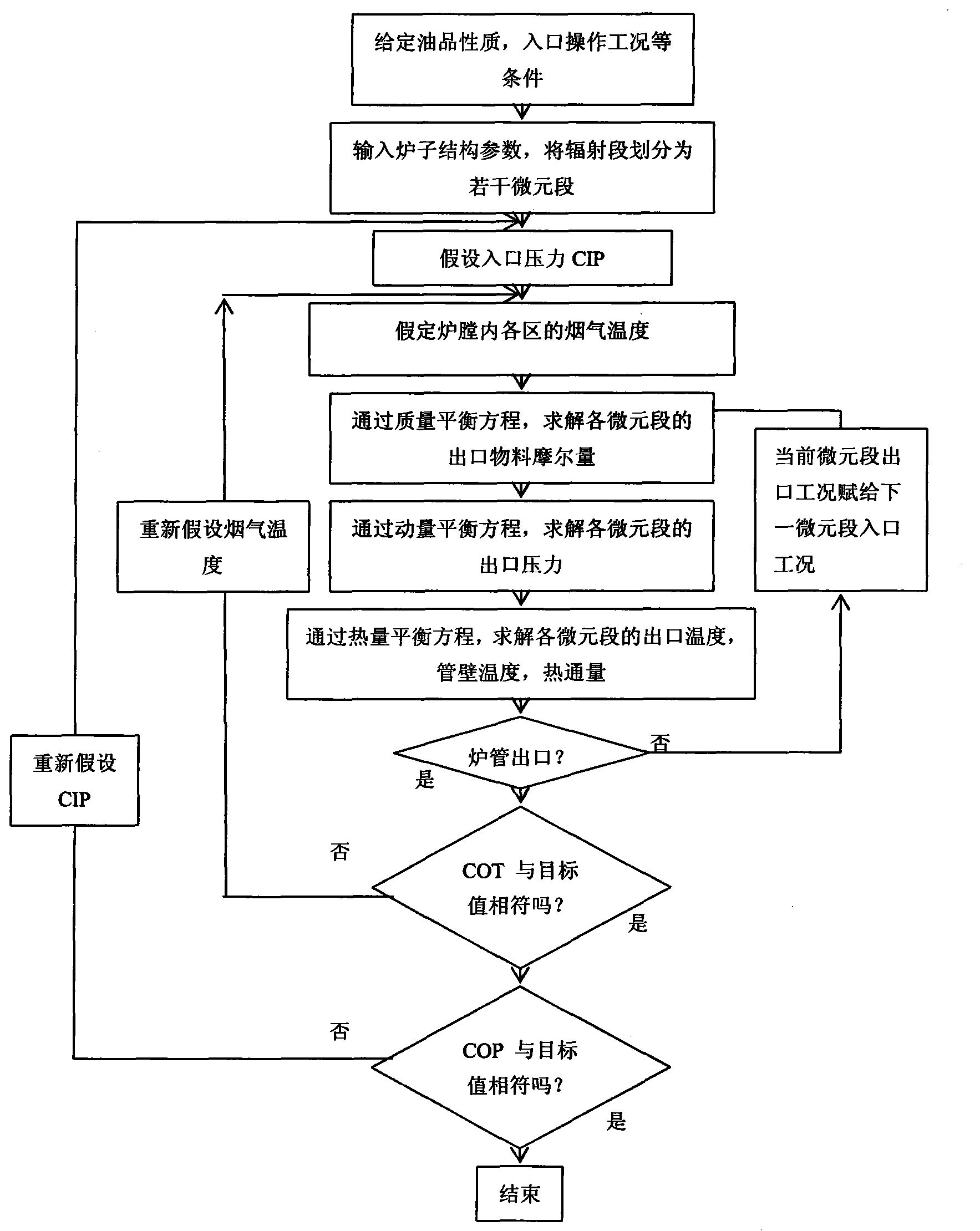

Method used

Image

Examples

Embodiment Construction

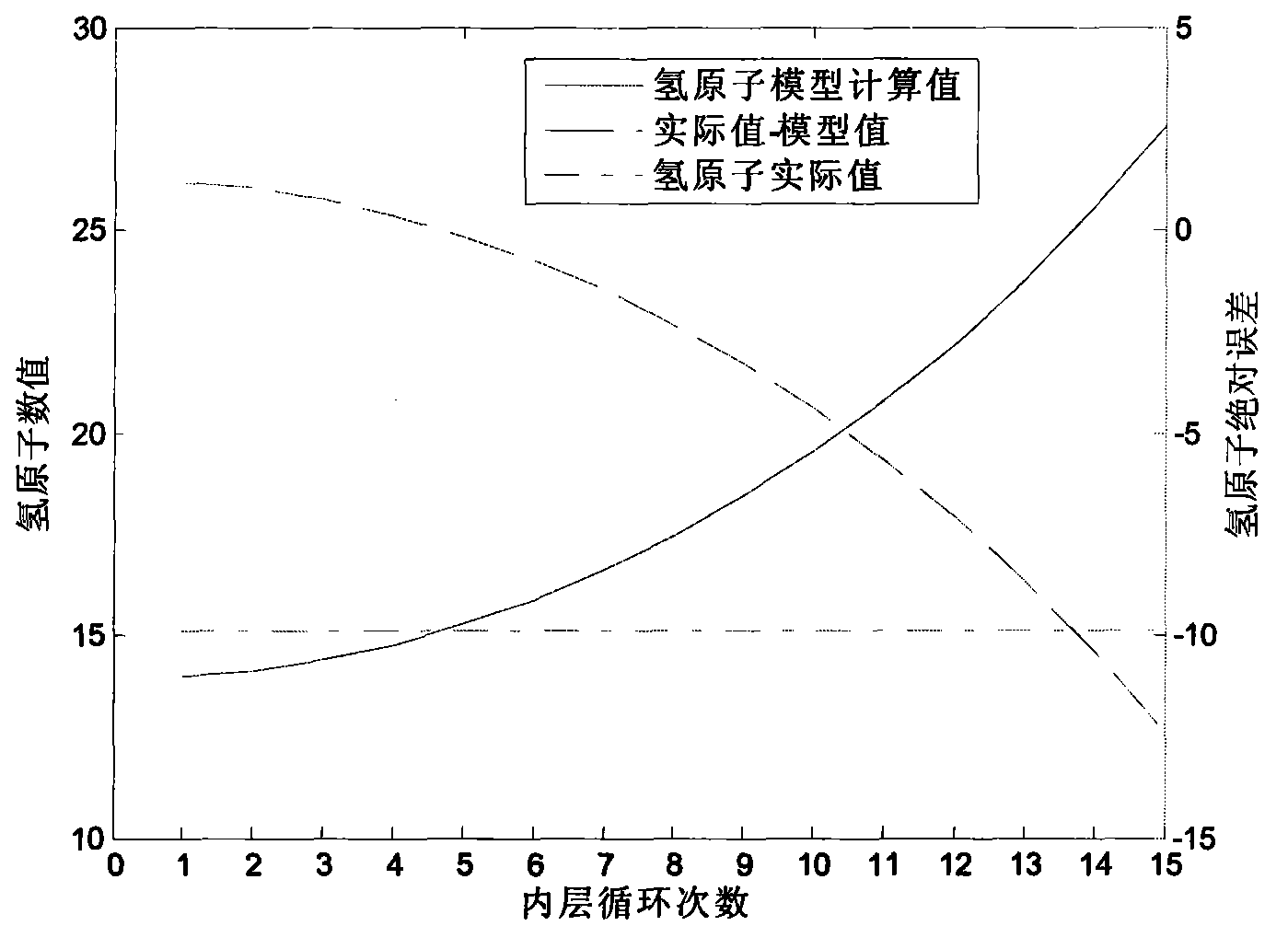

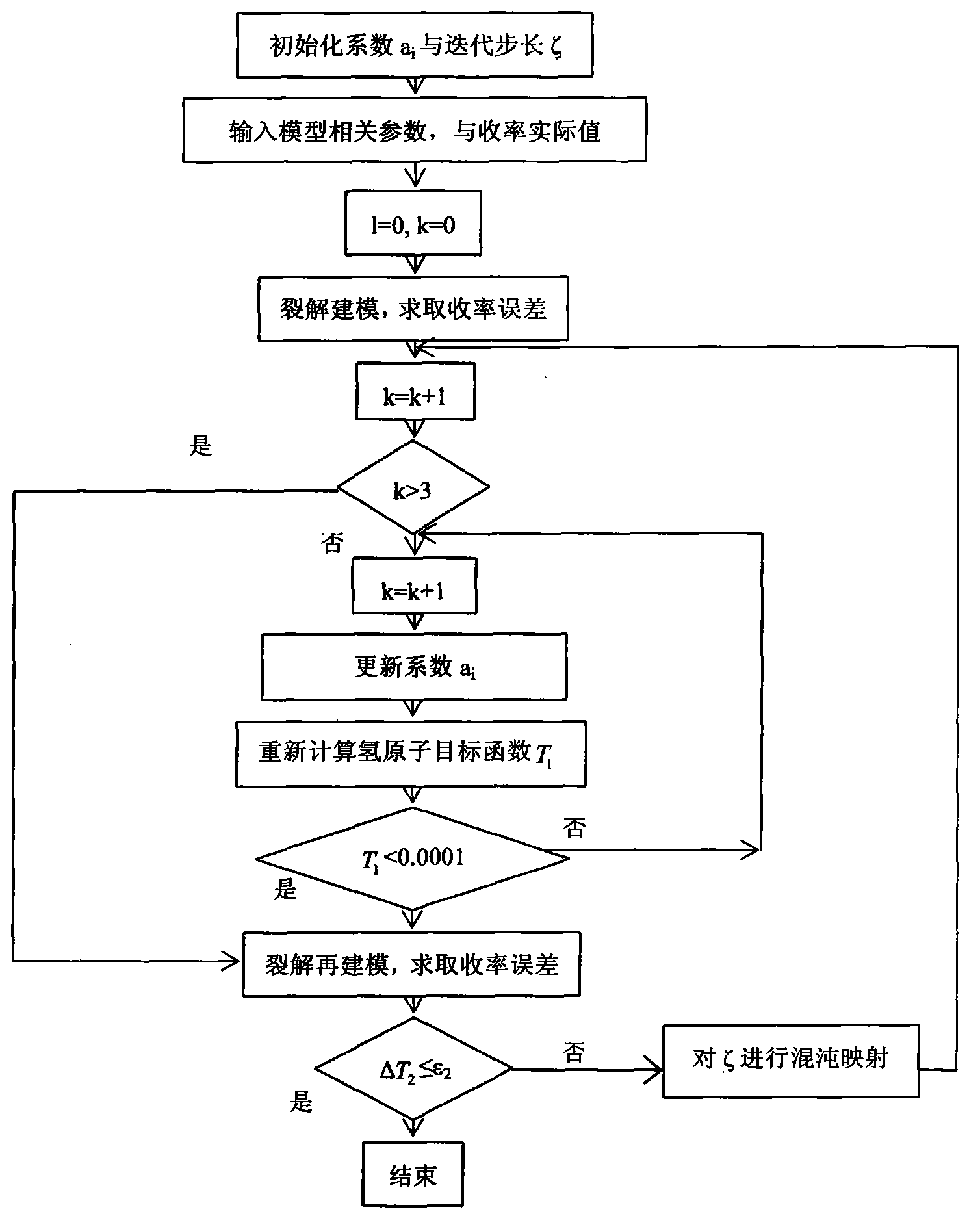

[0085] Aiming at the defects or insufficiencies of the Kumar molecular reaction dynamics model that cannot adapt to the properties of different naphthas, the present invention provides a kinetic model chaos optimization adjustment method and solution for naphtha high-temperature steam cracking to ethylene, and improves the model's ability to adapt to different naphthas. The adaptability of naphtha cracking improves the accuracy of the model and makes the model more widely applicable. The method of the present invention is realized by using a software system, and a software system is provided.

[0086] Specifically, the ethylene cracking dynamics optimization modeling source program is implemented through the browser / server structure, the display and input and output functions are implemented in the web interface, and the modeling and data transmission are implemented through the server calling the program file. Users can access and operate the interface through the Internet, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com