Method for preparing Ni-Re sponge oxide cathode

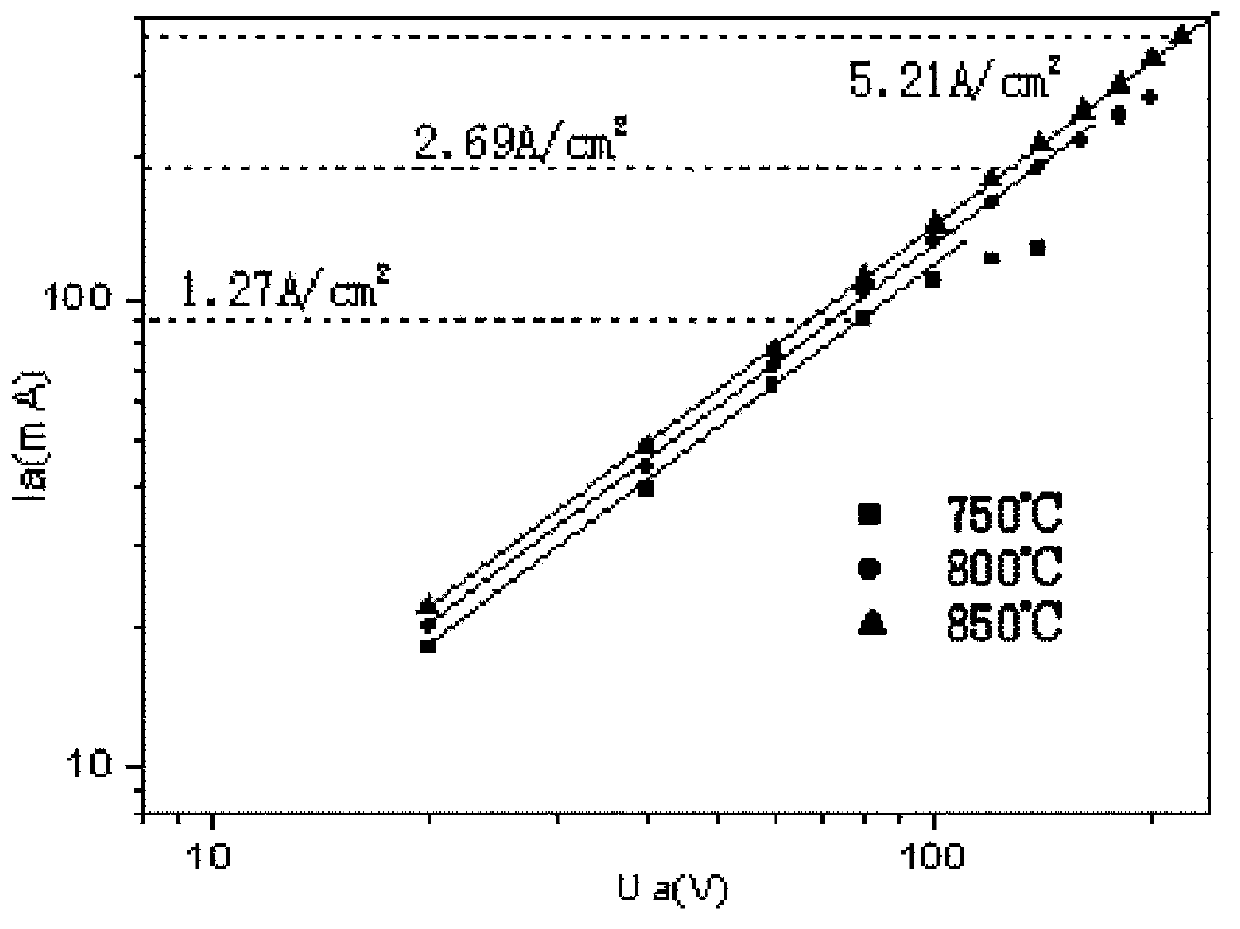

An oxide cathode, ni-re technology, applied in the field of electric vacuum, can solve the problems of reduced cathode activity and end of cathode life, and achieve the effects of reducing cathode temperature, enhancing cathode activity, and increasing emission current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

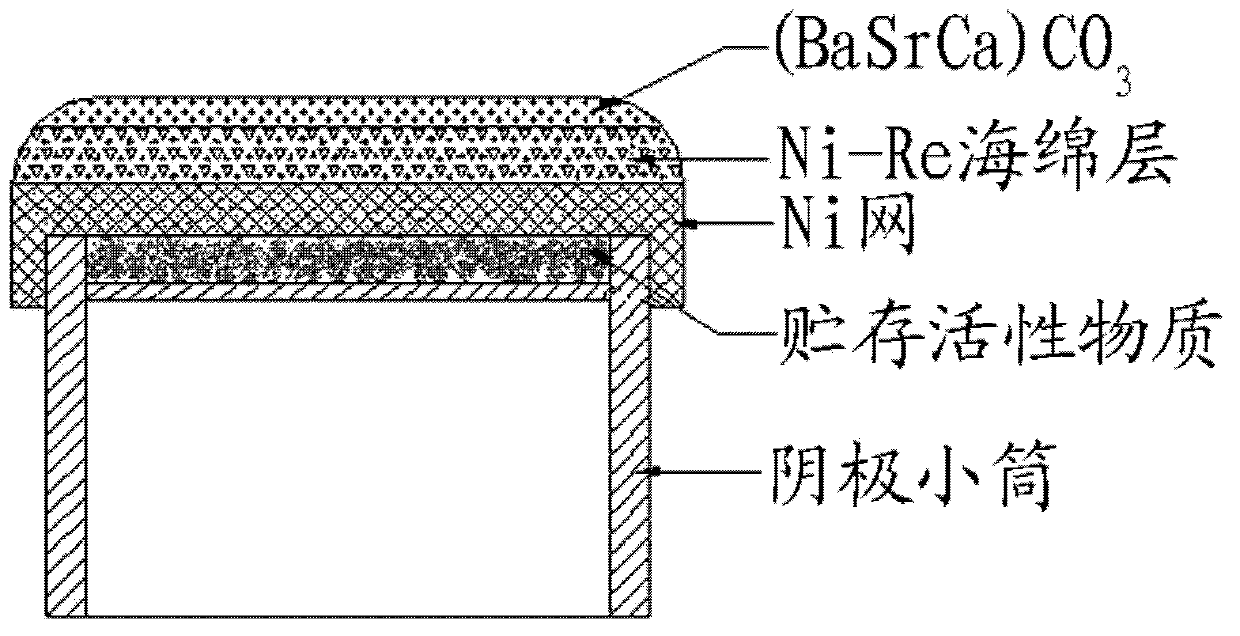

[0014] The method for preparing Ni-Re sponge oxide cathode of the present invention comprises the steps:

[0015] Step a, prepare NH 4 ReO 4 (Ammonium perrhenate) aqueous solution.

[0016] According to the present invention, any existing method can be used to prepare NH 4 ReO 4 Aqueous solutions, however, need to ensure that NH 4 ReO 4 The mass ratio to water is 1:15 to 1:5, preferably 1:10.

[0017] In a specific embodiment of the present invention, the NH 4 ReO 4 Crystal powder dissolved in deionized water, NH 4 ReO 4 Crystal powder accounted for less than 10% by mass of deionized water, heating the solution to above 60°C, to NH 4 ReO 4 The crystals are completely dissolved to produce NH 4 ReO 4 aqueous solution.

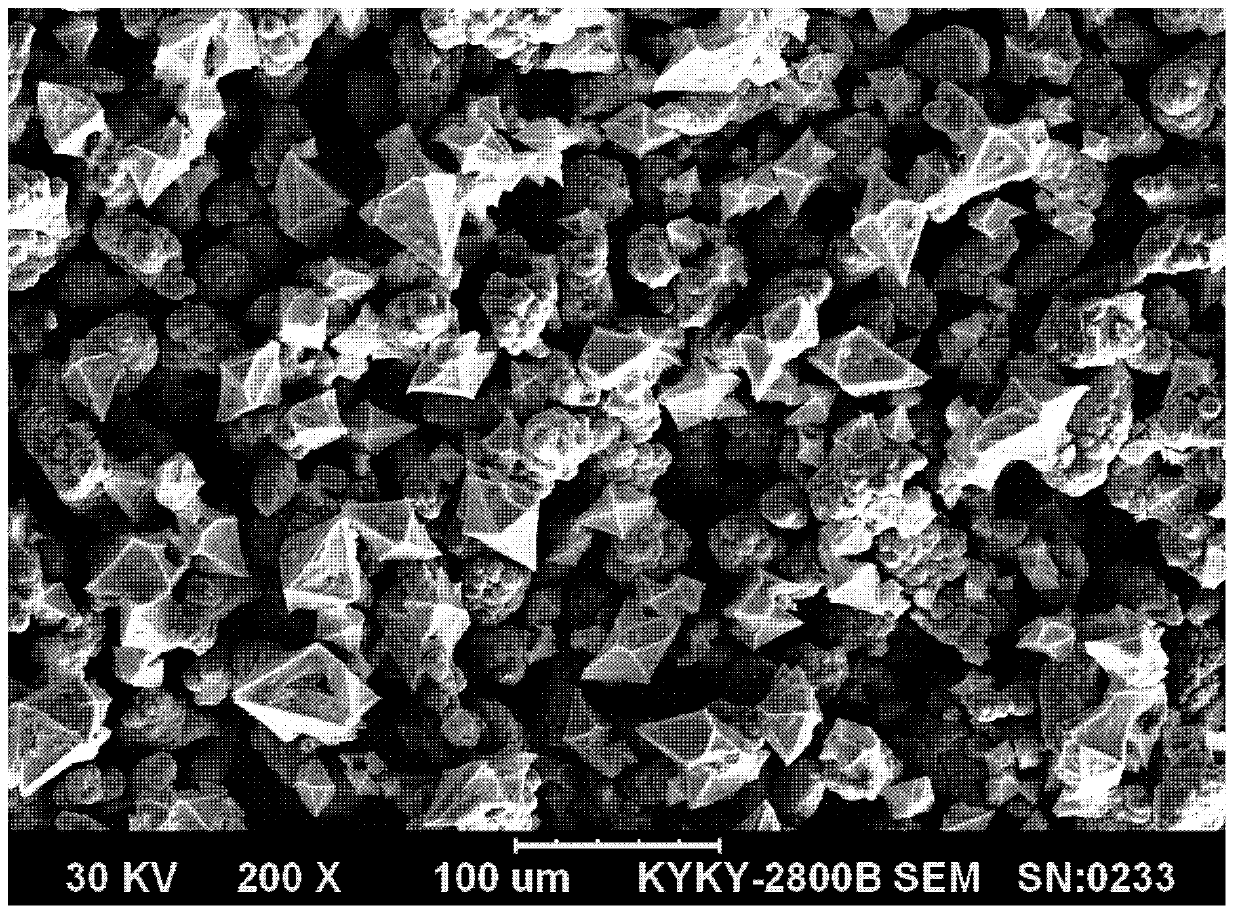

[0018] Step b. Dip the Ni mesh sintered with the Ni sponge layer into the NH 4 ReO 4 In the aqueous solution, NH is adsorbed in the Ni sponge layer 4 ReO 4 .

[0019] According to the present invention, the Ni mesh can be a Ni substrate, the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com