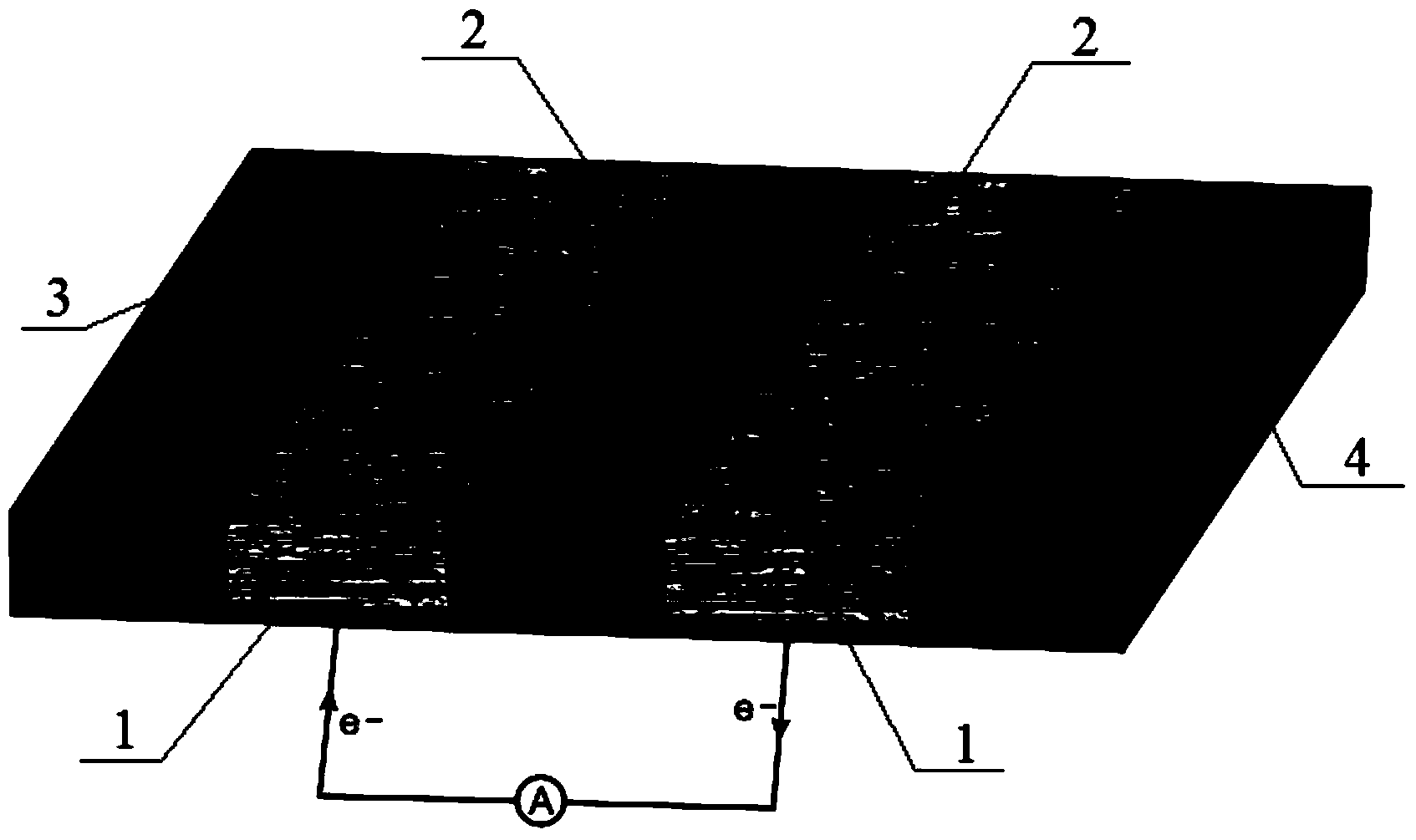

Micro membrane-free fuel cell with three-dimensional porous carbon electrode and preparation method thereof

A porous carbon electrode, fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of low fuel utilization rate and low power density, and achieve high fuel utilization rate and power density, large specific surface area, high efficiency Effects of Diffusion/Convective Mass Transport Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A micro-filmless fuel cell containing a three-dimensional porous carbon electrode is prepared by the following method, specifically comprising the following steps:

[0029] (1) Prepare metal electrode leads on the substrate:

[0030] 1.1 Prepare a layer of chromium metal film on the cleaned glass sheet (substrate) by magnetron sputtering method, and the chromium metal film is used as the lead wire of the carbon electrode. The process parameters of the magnetron sputtering method are: chamber pressure 0.6Pa, sputtering power 100W, argon flow rate 12cm 2 / min, sputtering time 2min;

[0031] 1.2 Use a coating machine to coat a layer of photoresist on the chromium metal film. The process parameters of coating are: low speed about 800rpm, time 6s, high speed 3500rpm, time 30s;

[0032] 1.3 Perform photolithography, development and other treatments on the photoresist, pattern the photoresist, so that the residual photoresist on the chromium metal film presents the required ...

Embodiment 2

[0039] A micro-filmless fuel cell containing a three-dimensional porous carbon electrode is prepared by the following method, specifically comprising the following steps:

[0040] (1) Prepare metal electrode leads on the substrate:

[0041] 1.1 Prepare a layer of chromium metal film on the cleaned silicon wafer (substrate) by magnetron sputtering method. The process parameters of magnetron sputtering method are: chamber pressure 0.5Pa, sputtering power 80W, argon flow rate 10cm 2 / min, sputtering time 3min;

[0042] 1.2 Use a coating machine to coat a layer of photoresist on the chromium metal film. The process parameters for coating are: low speed 700rpm, time 9s, high speed 3500rpm, time 20s;

[0043] 1.3 Perform photolithography, development and other treatments on the photoresist, pattern the photoresist, so that the residual photoresist on the chromium metal film presents the required electrode pattern, and then put it into the chromium etching solution to etch and remov...

Embodiment 3

[0050] A micro-filmless fuel cell containing a three-dimensional porous carbon electrode is prepared by the following method, specifically comprising the following steps:

[0051] (1) Preparing metal electrode leads on the substrate: same as Example 1;

[0052] (2) Loading carbon nanotubes on the metal electrode leads: deposit carbon nanotubes on the surface of the metal electrode leads by electrophoretic deposition, add 2g of carbon nanotubes to 1L of water, and prepare an aqueous solution of carbon nanotubes with a concentration of 2g / l. Apply a voltage of 1V and deposit for 10 hours to obtain carbon nanotubes supported on metal electrode leads, and the thickness of the carbon nanotubes is about 0.5mm;

[0053] (3) Catalyst loading on carbon nanotubes: soak the substrate loaded with metal electrode leads and carbon nanotubes in a solution containing chloroplatinic acid and silver nitrate for 18 hours, take it out at room temperature and dry it with hydrogen plasma Reduction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com