Improvement method of compound glycyrrhiza oral solution production technology

A technology of licorice oral liquid and production process, which can be applied to pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. problems, to achieve the effect of reducing precipitates, maintaining chemical balance, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

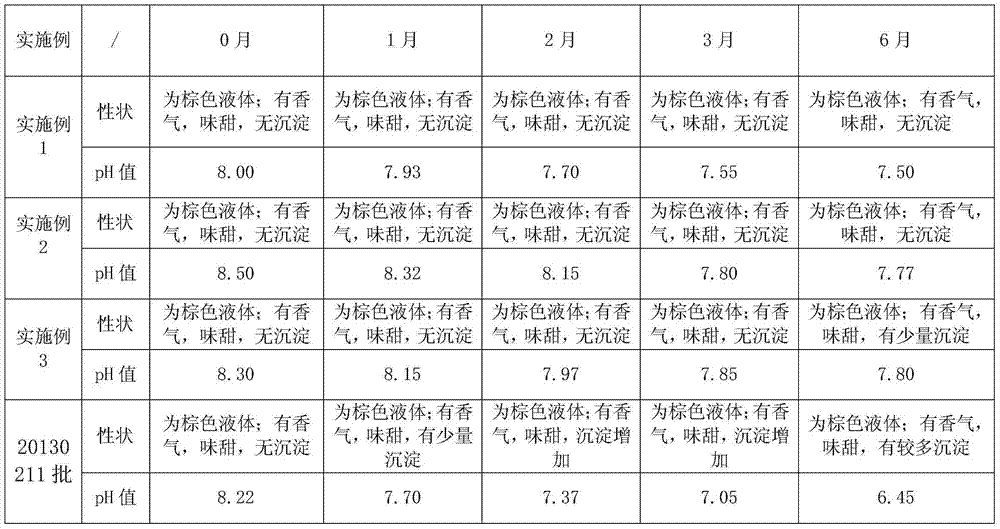

Embodiment 1

[0016] An improved method for the production process of compound licorice oral liquid, comprising the following steps:

[0017] 1. Take 1200ml of licorice liquid extract, add 1200ml of glycerin, mix well, add 5000ml of water to dilute, then slowly add an appropriate amount of concentrated ammonia solution, adjust the pH value to 8.00, and obtain the licorice liquid extract solution;

[0018] 2. Take 50g of guaiacol glycerin ether, add appropriate amount of hot water to dissolve, and make guaiacol glycerin ether solution;

[0019] 3. Add guaiacol glyceryl ether solution to the liquid extract solution of licorice, stir as it is added, then add 100 g of sodium alginate and 50 g of sodium carboxymethyl cellulose, stir to dissolve, and obtain a mixed solution;

[0020] 4. Add 1800ml of compound camphor tincture to the mixed solution, stir well, slowly add an appropriate amount of concentrated ammonia solution, adjust the pH value of the solution to 8.00, add appropriate amount of w...

Embodiment 2

[0022] An improved method for the production process of compound licorice oral liquid, comprising the following steps:

[0023] 1. Take 1200ml of licorice liquid extract, add 1200ml of glycerin, mix well, add 5000ml of water to dilute, slowly add an appropriate amount of concentrated ammonia solution, adjust the pH value to 9.00, and obtain the licorice liquid extract solution;

[0024] 2. Take 50g of guaiacol glycerin ether, add appropriate amount of hot water to dissolve, and make guaiacol glycerin ether solution;

[0025] 3. Add guaiacol glyceryl ether solution to the liquid extract solution of licorice, stir as it is added, then add 100 g of sodium alginate and 50 g of sodium carboxymethyl cellulose, stir to dissolve, and obtain a mixed solution;

[0026] 4. Add 1800ml of compound camphor tincture to the mixed solution, stir well, slowly add an appropriate amount of concentrated ammonia solution, adjust the pH value of the solution to 8.50, add appropriate amount of water ...

Embodiment 3

[0028] An improved method for the production process of compound licorice oral liquid, comprising the following steps:

[0029] 1. Take 1200ml of licorice liquid extract, add 1200ml of glycerin, mix well, add 5000ml of water to dilute, slowly add an appropriate amount of concentrated ammonia solution, adjust the pH value to 8.50, and obtain the licorice liquid extract solution;

[0030] 2. Take 50g of guaiacol glycerin ether, add appropriate amount of hot water to dissolve, and make guaiacol glycerin ether solution;

[0031] 3. Add guaiacol glyceryl ether solution to the liquid extract solution of licorice, stir as it is added, then add 100 g of sodium alginate and 50 g of sodium carboxymethyl cellulose, stir to dissolve, and obtain a mixed solution;

[0032] 4. Add 1800ml of compound camphor tincture to the mixed solution, stir well, slowly add an appropriate amount of concentrated ammonia solution, adjust the pH value of the solution to 8.30, add appropriate amount of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com