Implant material with PRF precursor liquid solidified into gel mask

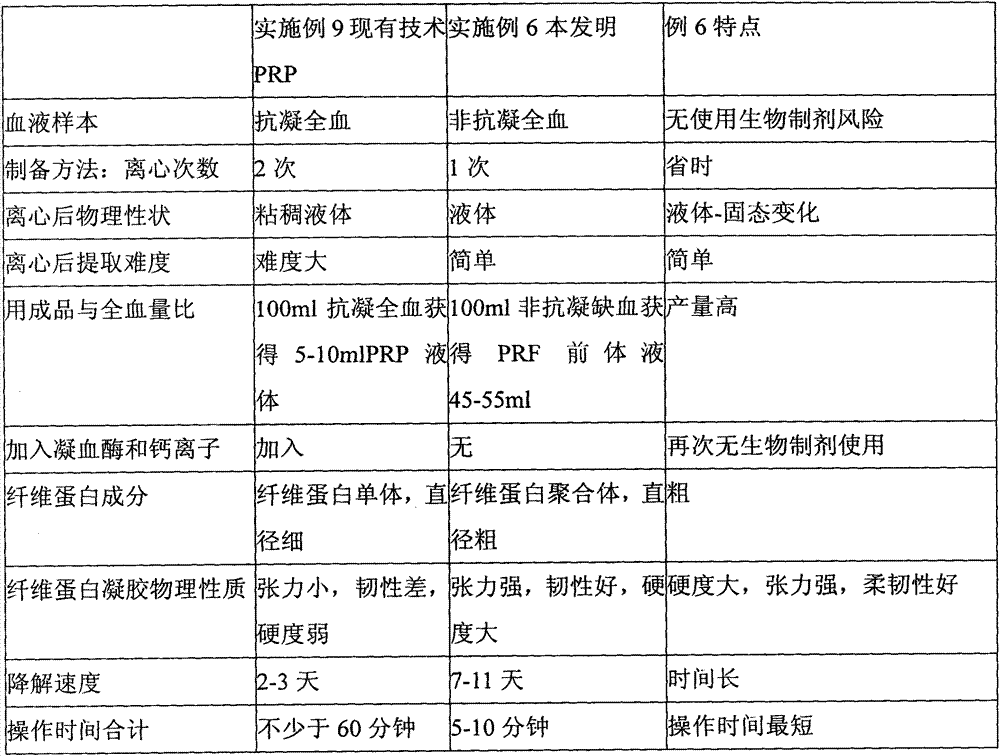

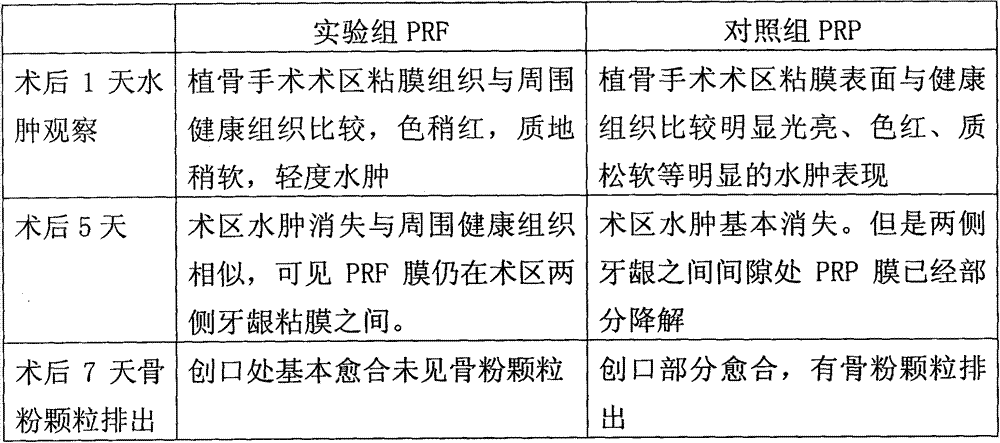

A technology of implant material and gel film, which is applied in prosthetics, medical science, etc., can solve the problems of high risk in the use of biological agents and complicated operation, and achieve the effect of strong tension, simple operation, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Collect 4ml of non-anticoagulated blood sample with a vacuette tube without any biological agent, immediately put it into a centrifuge (Anke TDL-80-2D China), adjust the centrifugal force at 130g, and centrifuge for 4 minutes; take out the stratified blood sample, the upper layer It is a turbid light yellow liquid, the lower layer is the red blood cell layer, and the middle buffy coat layer is very unclear; transfer the entire upper layer of turbid light yellow liquid into a ceramic double dish and mix well; let it stand at room temperature for about 30 minutes, and all the yellow liquid stops, and the liquid becomes In a turbid solid state, flatten it with a metal plate to prepare a film; pick it up with tweezers, and it has elasticity, toughness and hardness.

Embodiment 2

[0028] Collect 4ml of non-anticoagulated blood sample with a vacuette tube that does not contain any biological agents, immediately put it into a centrifuge (Anke TDL-80-2D China), adjust the centrifugal force at 270g, and centrifuge for 3 minutes; take out the stratified blood sample, the upper layer It is a turbid light yellow liquid, the lower layer is the red blood cell layer, and the middle buffy coat layer is very unclear; transfer the entire upper layer of turbid light yellow liquid into a ceramic double dish and mix well; let it stand at room temperature for 30 minutes, all the yellow liquid stops, and the liquid becomes turbid Solid state, flattened with a metal plate to prepare a film; clamped with tweezers, elastic, tough and hard, not easy to break when torn

Embodiment 3

[0030] Collect 4ml of non-anticoagulated blood sample with a vacuette tube without any biological agent, immediately put it into a centrifuge (Anke TDL-80-2D China), adjust the centrifugal force at 390g, and centrifuge for 2 minutes; take out the stratified blood sample, the upper layer It is a turbid light yellow liquid, the lower layer is the red blood cell layer, and the middle buffy coat layer is very unclear; transfer the entire upper layer of turbid light yellow liquid into a ceramic double dish and mix well; let it stand at room temperature for 35 minutes, all the yellow liquid stops, and the liquid becomes turbid Solid state, flattened with a metal plate to form a film; clamped with tweezers, it has elasticity, toughness and hardness, and is not easy to break when torn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com