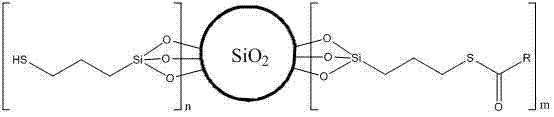

Silicon dioxide pellet with sulfur silane modified surface and synthesis method of pellet

A technology of silica and synthesis method, which is applied in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve the problems of leaving pores, affecting rubber performance, waste, etc., to reduce porosity, reduce carbon emissions, and synthesis method reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of silica microspheres with surface modified by mercaptopropylsilane

[0033] In a 2000mL three-neck flask equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, add 100g of 2 / g silica microspheres, add 1000g ethanol, add 1mL concentrated hydrochloric acid, adjust the pH value of the system to around 2, start mechanical stirring, dissolve 1g (4.2mmol) 3-mercaptopropyltriethoxysilane in 5mL In the water ethanol, slowly drop it through the constant pressure dropping funnel. After the dropwise addition, turn on the heating to reflux. After reacting for 5 hours, the gas chromatography detects that the 3-mercaptopropyltriethoxysilane has basically reacted, stop Heating, cooling to room temperature, filtering, washing the solid several times with absolute ethanol, checking the pH value of the washed ethanol, when the washed ethanol is neutral, collecting the solid product, and vacuum drying at 60°C for 6 hours to obta...

Embodiment 2

[0037] 1. Preparation of silica microspheres with surface modified by mercaptopropylsilane

[0038] In a 2000mL three-neck flask equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, add 300g of 2 / g of silica microspheres, add 1000g of methanol, add 3g of strong acidic cation exchange resin, start mechanical stirring, slowly drop 30g (0.153mol) of 3-mercaptopropyltrimethoxysilane through the constant pressure dropping funnel, After the dropwise addition, turn on and heat to reflux. After 5 hours of reaction, gas chromatography detects that the 3-mercaptopropyltriethoxysilane has basically reacted. Stop heating, cool down to room temperature, filter, and wash the solid with anhydrous methanol for 3 The second time, the solid was collected, and after vacuum drying at 60°C for 6 hours, the resin and silica microspheres were separated with a sieve with a pore size of about 0.3 mm to obtain 299.5 g of a white solid product of silica micr...

Embodiment 3

[0042] 1. Preparation of silica microspheres with surface modified by mercaptopropylsilane

[0043] In a 2000mL three-neck flask equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, add 200g of 2 / g of silica microspheres, add 1000g n-hexane, add 0.5mL sulfuric acid, the pH of the system is about 1, start mechanical stirring, dissolve 10g (42mmol) 3-mercaptopropyltriethoxysilane in 50mL n-hexane Slowly drop it through the constant pressure dropping funnel, after the drop is completed, turn on the heating to reflux, after reacting for 5 hours, take a sample of the n-hexane layer solution, and detect the 3-mercaptopropyltriethoxysilane in it by gas chromatography After the reaction was completed, the heating was stopped, the temperature was lowered to room temperature, filtered, the solid was washed several times with n-hexane, and the solid product was collected. After vacuum drying at 60° C. for 6 hours, 194.0 g of a white solid pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com