A kind of modified nano silicon dioxide and preparation method thereof

A nano-silica and modification technology, applied in the field of nano-silica modification, can solve the problems of difficulty in obtaining uniform dispersion, easy agglomeration, and high surface energy, and achieve good toughness, good dispersibility, and reasonable synthesis methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

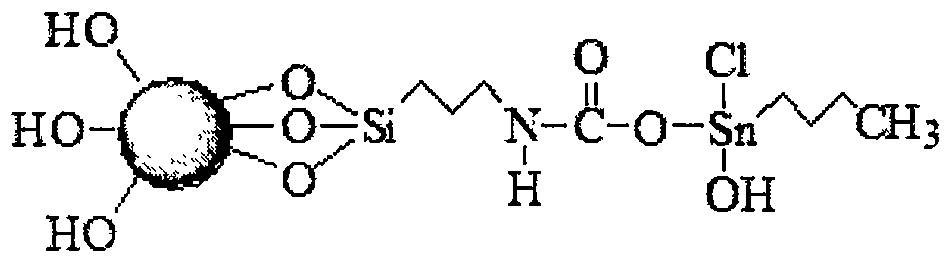

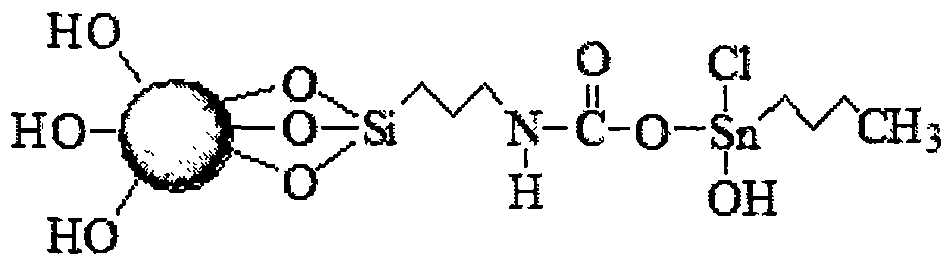

Image

Examples

preparation example Construction

[0017] The preparation method of the nano silicon dioxide modified by tin catalyst of the present invention comprises the following steps:

[0018] Step (1): Nano silica and cationic surfactant are dispersed in an organic solvent to obtain a uniformly dispersed mixed solution;

[0019] Step (2): adding an isocyanate silane coupling agent to the mixed solution described in step (1), and reacting to obtain nano-silica modified by an isocyanate silane coupling agent;

[0020] Step (3): reacting the isocyanate-based silane coupling agent-modified nano-silica obtained in step (2) with a catalyst to obtain catalyst-modified nano-silica.

[0021] [Step (1): Nano silica and cationic surfactant are dispersed in an organic solvent to obtain a uniformly dispersed mixture]

[0022] Add a certain amount of cationic surfactant to an appropriate amount of organic solvent, the electromagnetic stirring speed is 400-600r / min, the temperature is 50-70°C, and the stirring time is 10-60min to obt...

Embodiment 1

[0039] Disperse 10g of tetraoctylammonium bromide in 1500ml of xylene, the electromagnetic stirring speed is 500r / min, and magnetically stir for 20min to obtain solution A; 50g of nano silicon dioxide is added to solution A, and ultrasonic treatment is performed for 1h to obtain Uniformly dispersed mixture B.

[0040] Put the mixed liquid B into the condensing reflux device, under N 2 Under protection, 10 ml of triethoxysilane isocyanate coupling agent was added dropwise, and reacted in an oil bath at 80° C. for 24 hours. After the reaction is completed, the product is separated and washed several times with xylene to obtain nano silicon dioxide modified by grafted silane coupling agent.

[0041] The above-mentioned modified nano-silica was again ultrasonically dispersed in xylene, N 2 Protected and magnetically stirred, 15g of catalyst was added, the reaction temperature was 80°C, and the reaction was carried out for 6h. After the reaction is completed, the product is sepa...

Embodiment 2

[0044] Using the catalyst-modified nano-silica prepared in Example 1, a pCBT nanocomposite material with 5 wt% catalyst-modified nano-silica was prepared. The fracture absorption energy of this composite material is 610J, compared with 370J of the pure pCBT composite material, its toughening effect is increased by about 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com