Method for preparing hydroxy fatty acids by utilizing swill-cooked dirty oil

A technology of hydroxy fatty acid and waste oil, which is applied in the chemical field, can solve the problem of secondary utilization of waste oil, etc., and achieve the effect of simple process and stable product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

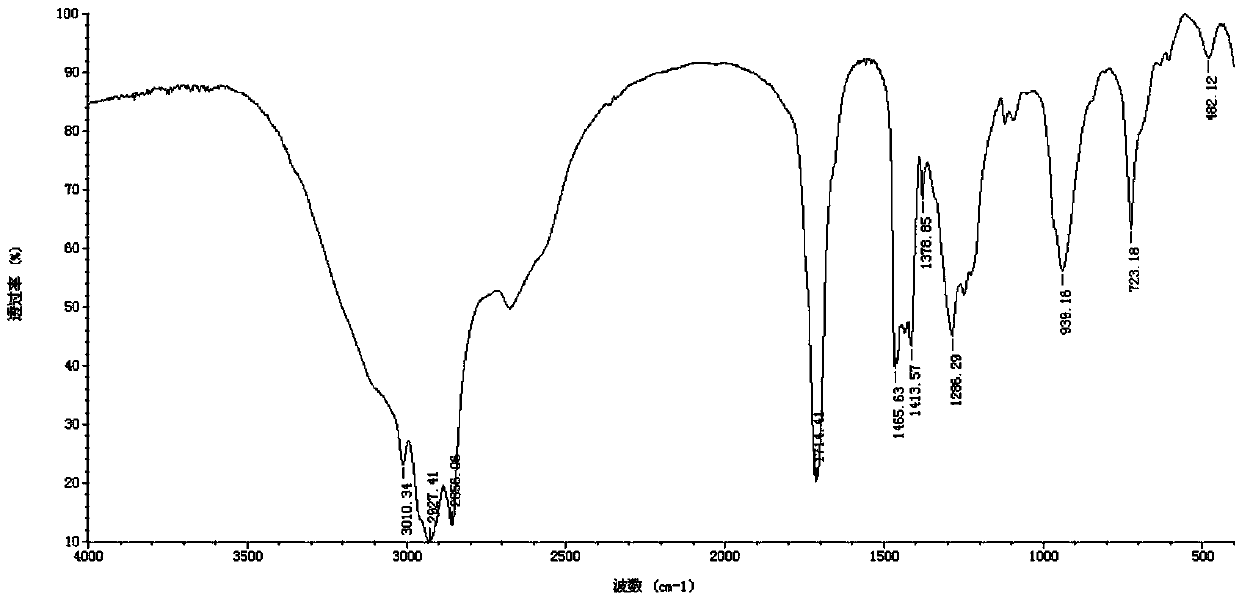

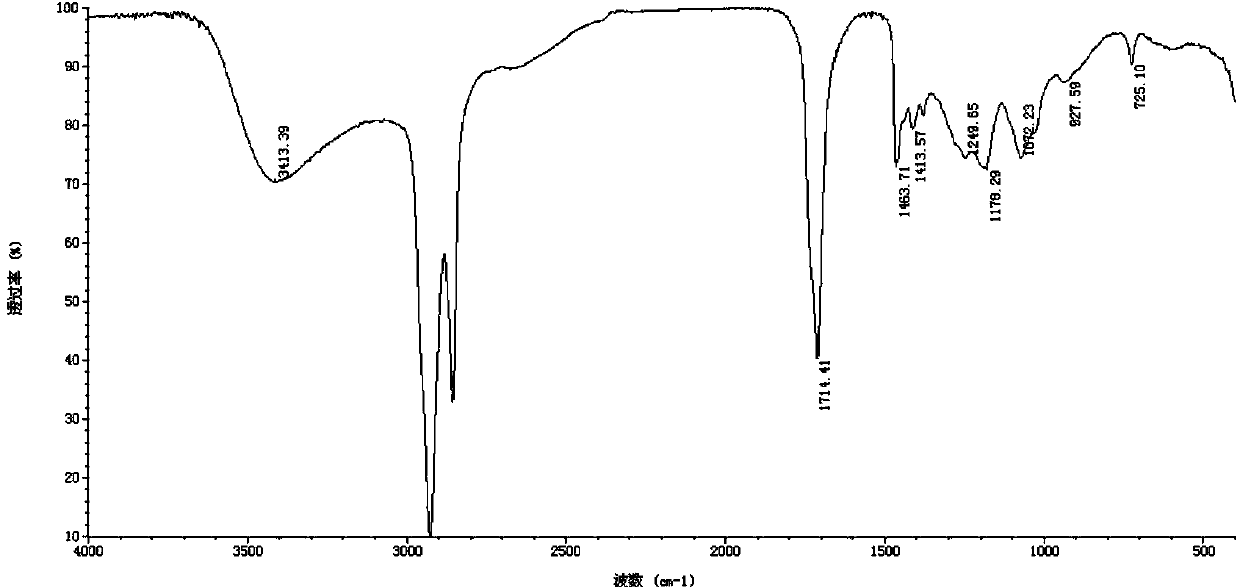

Image

Examples

specific Embodiment 1

[0055] Waste oil pretreatment: Now stir and heat the recovered 10kg waste oil to 85°C, keep it warm for 20 minutes, cool down to settle, and centrifuge to separate out impurities; Activated clay was added to the waste oil from which impurities were separated, and the quality of the added activated clay was 0.3 kg; heated to 95° C., kept for 1 hour, filtered to remove the activated clay, and 9.4 kg of refined waste oil was obtained.

[0056] Preparation of waste oil fatty acid: add 9.4 kg of refined waste oil to the reaction kettle according to the ratio, then add 3.66 kg of sodium hydroxide solution with a mass concentration of 35%, heat up to 75 ° C, and react for 3 hours to obtain waste oil fatty acid sodium salt Cool down to 60°C, then add 3.25kg of concentrated hydrochloric acid with a mass concentration of 37% to the system, raise the temperature to 65°C, and react for 2 hours to obtain a mixture of waste oil fatty acids, leave it to separate and separate, and the upper la...

specific Embodiment 2

[0061] Waste oil pretreatment: Stir and heat 10kg of recovered waste oil to 90°C, keep it warm for 25 minutes, cool down to settle, and centrifuge to separate impurities; further decolorize and remove impurities from the waste oil that has been initially removed, and activate clay Add to the sewer oil centrifuged to separate impurities, the quality of the added activated clay is 0.4kg, heat to 100 ℃, keep warm for 1.5 hours, filter and remove the activated clay to obtain 9.25kg of refined waste oil.

[0062] Preparation of waste oil fatty acid: Add 9.25 kg of refined waste oil into the reaction kettle according to the proportion, then add 3.79 kg of sodium hydroxide solution with a mass concentration of 35%, raise the temperature to 80°C, and react for 3.5 hours to obtain waste oil fatty acid salt. Lower the temperature to 60°C, add 3.41 kg of concentrated hydrochloric acid with a mass concentration of 37% to the system, raise the temperature to 70°C, and react for 2 hours to o...

specific Embodiment 3

[0067] Waste oil pretreatment: Stir and heat recovered 10kg waste oil to 100°C, keep it warm for 25 minutes, cool down for sedimentation, and centrifuge to separate out impurities; further decolorize and remove impurities from the waste oil that has been initially removed. White clay is added in the waste oil of preliminary impurity removal, the quality of the added activated clay is 0.45kg, is heated to 110 ℃, is incubated for 1.5 hours, and the activated clay is removed by filtration to obtain 9.13kg of refined waste oil.

[0068] Preparation of waste oil fatty acid: Add 9.13 kg of refined waste oil into the reaction kettle according to the proportion, then add 3.92 kg of sodium hydroxide solution with a mass concentration of 35%, raise the temperature to 85°C, and react for 4 hours to obtain waste oil fatty acid sodium salt. Lower the temperature to 60°C, add 3.73 kg of concentrated hydrochloric acid with a mass concentration of 37% to the system, raise the temperature to 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap