Linear plasma-enhanced chemical vapor deposition system with remote magnetic-mirror field constraint

A plasma-enhanced chemical technology, applied in the field of ion and thin-film material science research, can solve problems such as unfavorable continuous operation of coating, achieve the effect of improving feasibility and flexibility, reducing development difficulty, and continuous deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

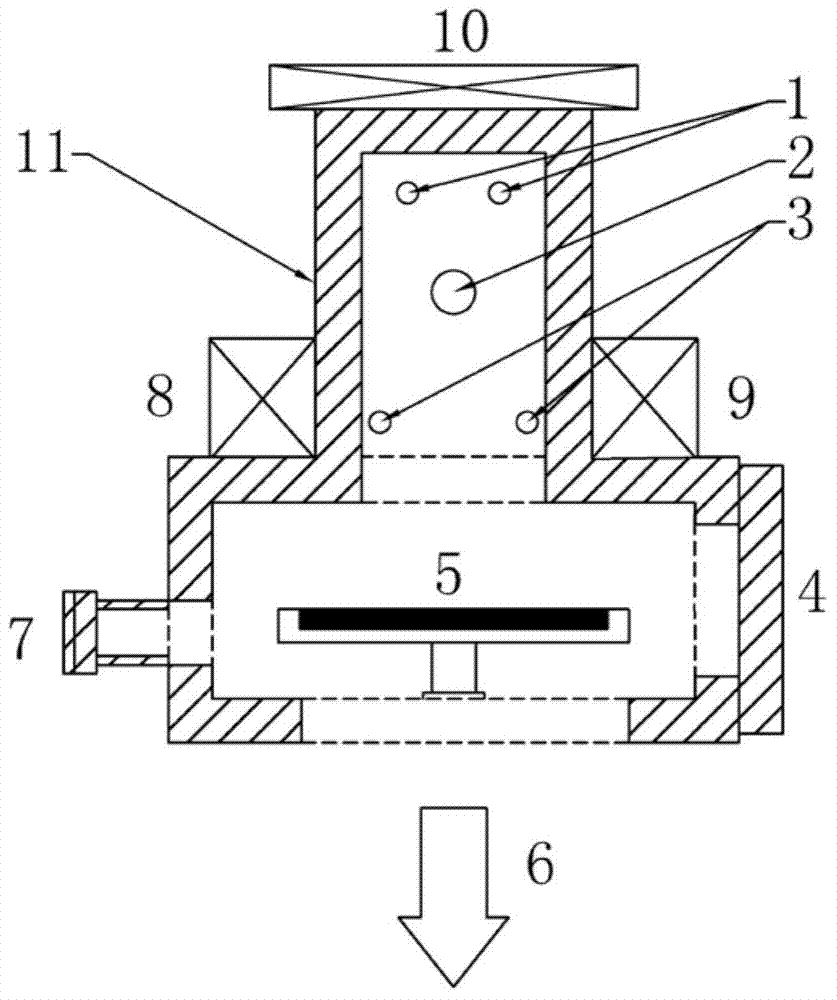

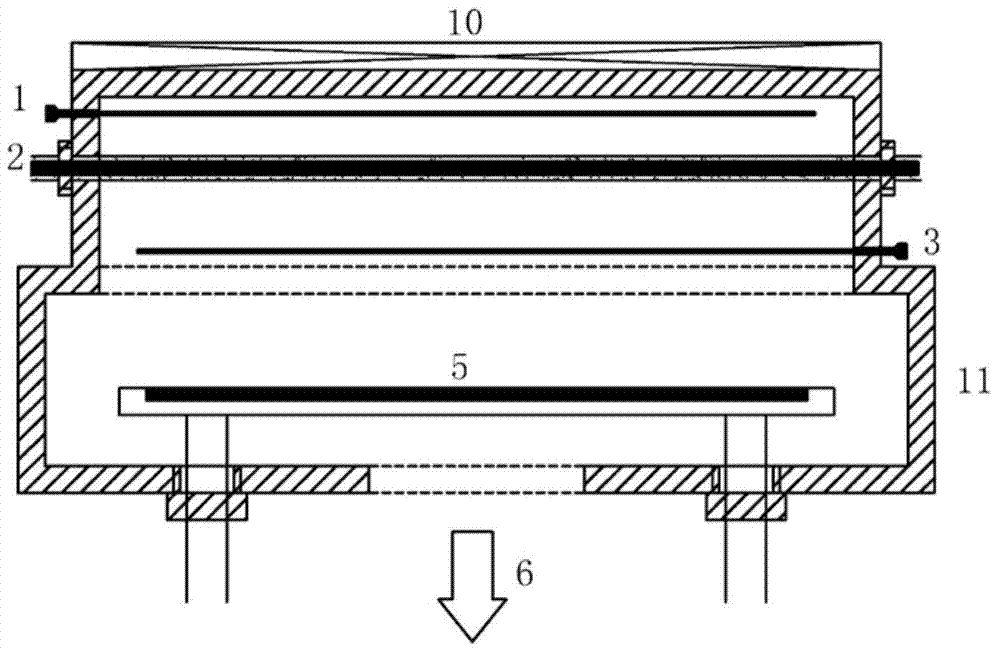

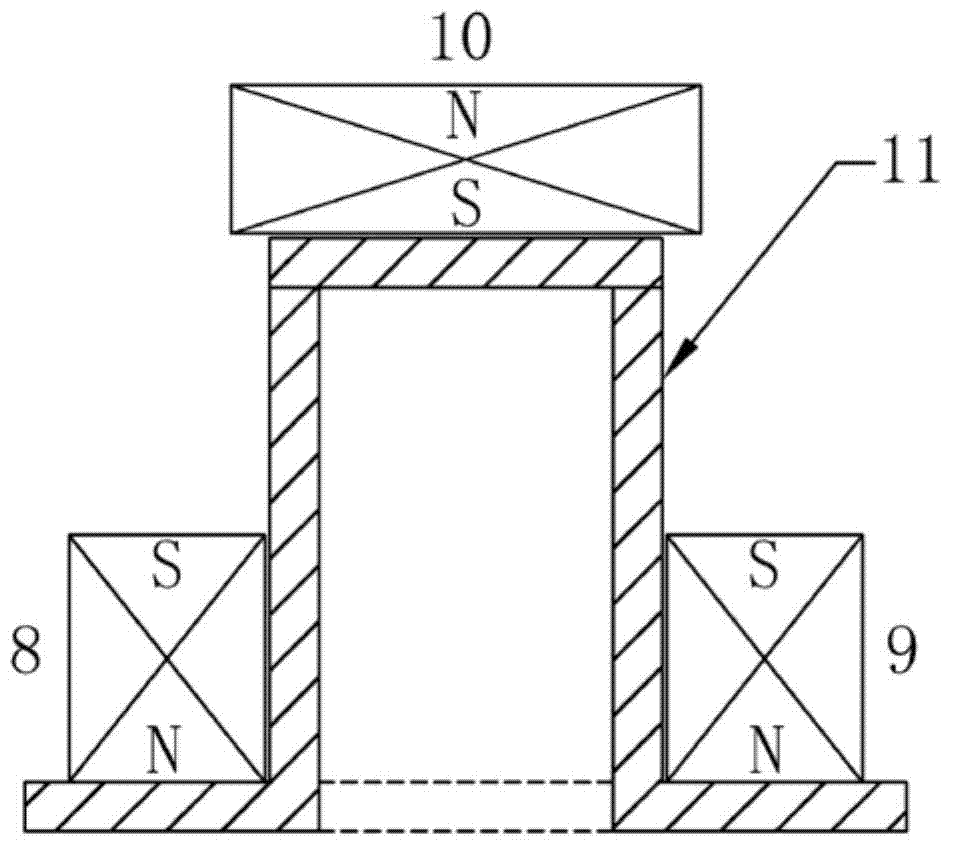

[0024] Such as figure 1 and figure 2 As shown, the remote magnetic mirror confined linear plasma enhanced chemical vapor deposition system includes inlet pipes 1 and 3 connected to the gas source, a coaxial circular waveguide 2 connected to the coaxial microwave source, and a "convex" shaped non-magnetic stainless steel A vacuum chamber 11, a rectangular deposition chamber door 4, an observation window 7, a built-in heating and biasing substrate table 5, a vacuum unit 6, and a magnetic field assembly composed of permanent magnets 8, 9, 10. In this remote magnetic mirror confined linear plasma enhanced chemical vapor deposition system, mechanical pump-molecular pump cascade vacuum unit 6 is used for vacuuming, and the background vacuum can reach 10 -4 Pa level. The working gas used for deposition enters the vacuum chamber through the upper inlet pipe 1 and the lower inlet pipe 3, wherein the inert gas and the reducing gas pass through the inlet pipe 1, and the reactive precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com