Army green zinc-coated chrome-free passivator II for bondy pipe

A passivating agent, color technology, applied in the direction of metal material coating process, etc., can solve the problems of non-toxic environmental protection, trivalent chromium toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific preparation steps of this embodiment are as follows:

[0019] Sodium molybdate 15g / L, nickel sulfate 25g / L, sodium citrate 10g / L, sodium sulfite 10g / L, oxalic acid 10g / L.

[0020] a. Pour 15g / L sodium molybdate into a small amount of water, stir to fully dissolve;

[0021] b. Slowly add 10g / L sodium citrate and 10g / L sodium sulfite, and stir to fully dissolve;

[0022] c. Pour in 10g / L oxalic acid and stir evenly;

[0023] d. Slowly add 25g / L of nickel sulfate, stir rapidly to make it fully dissolved;

[0024] e. After the calculated amount of water (conductivity < 5us / cm) was made to volume, it was left to stand for 10 minutes, and the pH was adjusted within the range of 2.5 with nitric acid.

[0025] f. Prepare a common low-cyanide zinc plating solution and adjust the pH value for electroplating.

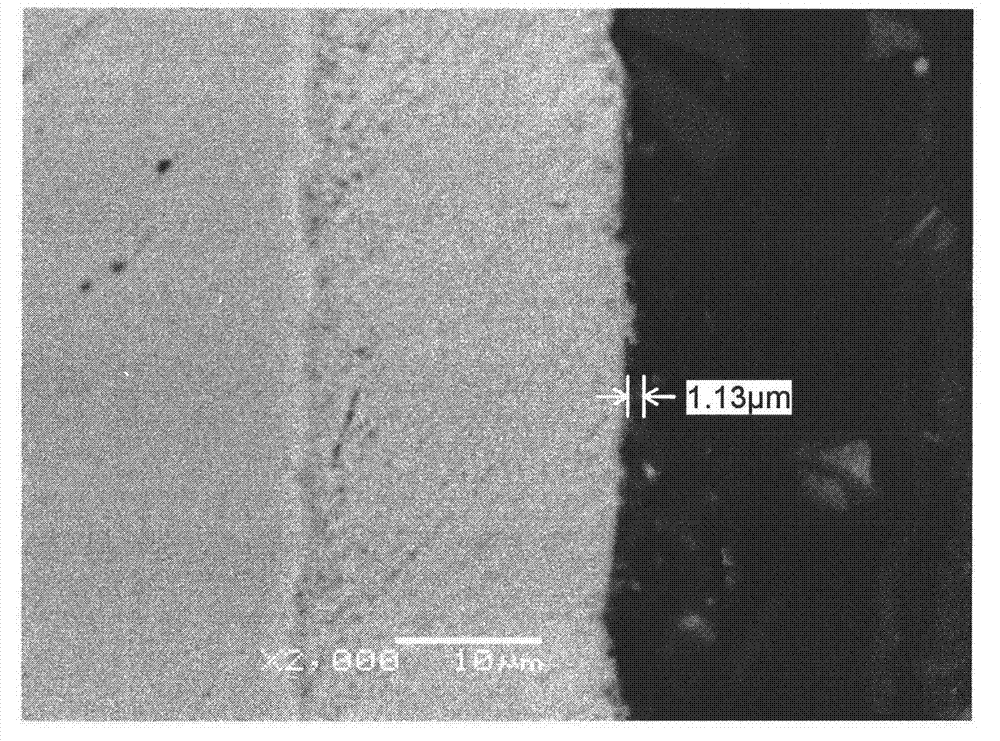

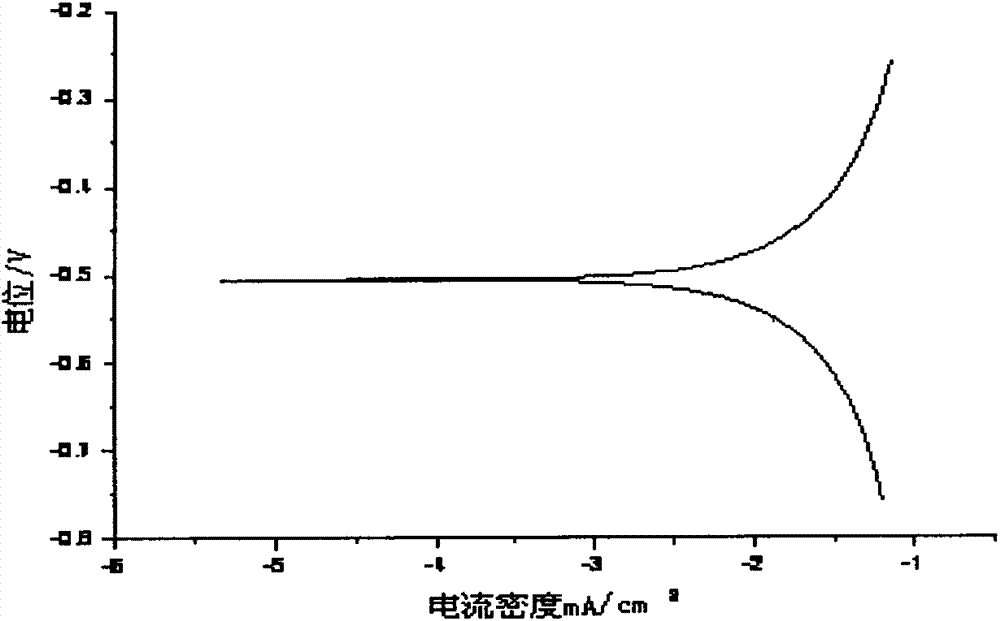

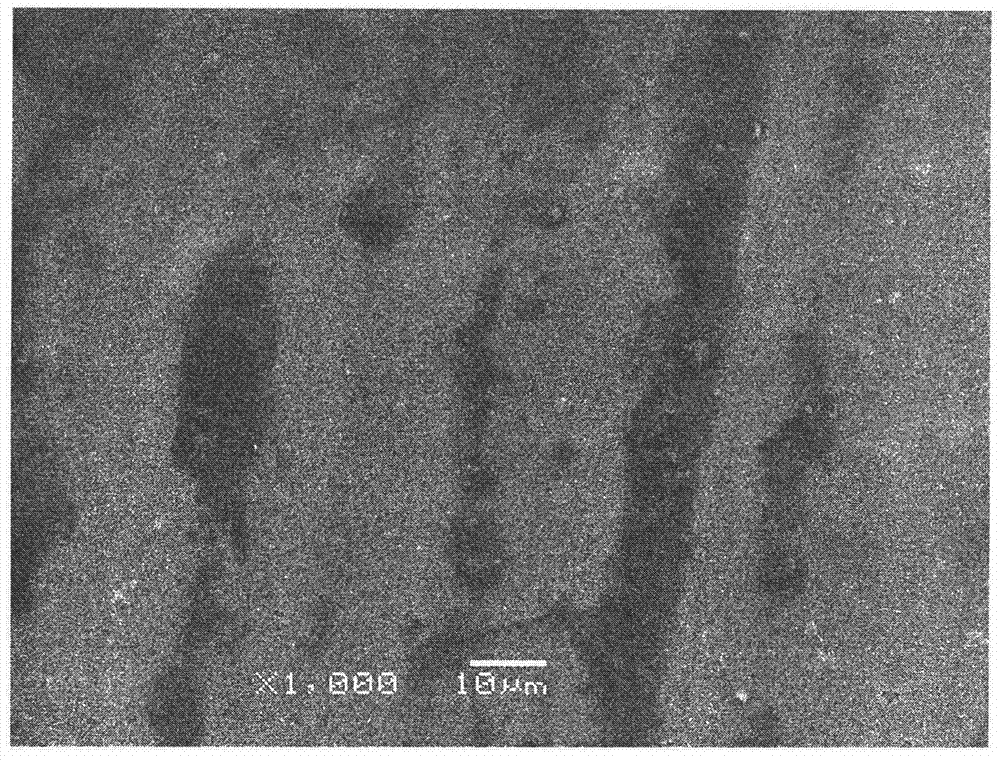

[0026] g. After a certain period of time, take out the sample, and conduct passivation treatment after light exposure in 3% nitric acid, and the passivatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com