High temperature resisting deep-circulation lead acid battery

A lead-acid battery, high temperature resistant technology, applied in the direction of lead-acid battery, lead-acid battery electrode, battery electrode, etc., can solve the problem of not being able to meet the deep cycle use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

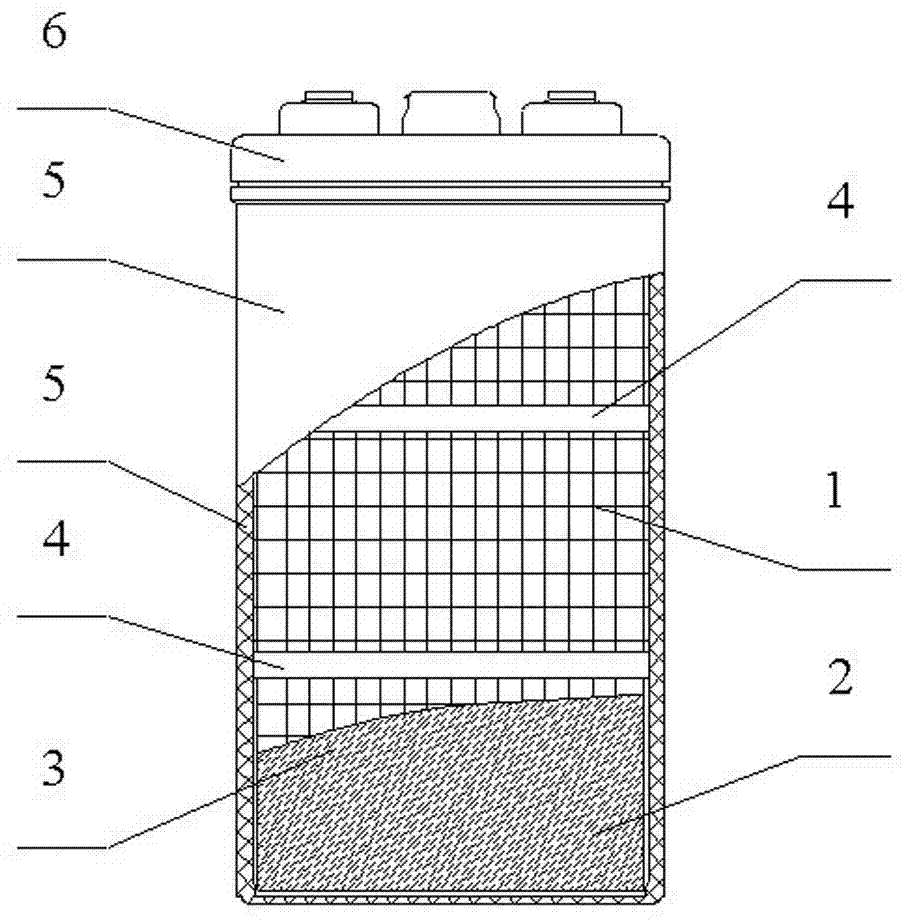

[0015] 1. The positive grid in grid 1 uses lead-calcium-tin-aluminum-silver five-element alloy, and silver is added to the existing lead-calcium-tin aluminum alloy, and the silver content accounts for 0.03% of the total weight of the alloy. The positive lead paste in lead paste 2 is added with 1.3% (weight percentage, the same below) of ultrafine rare earth oxide Y in the existing positive lead paste 2 O 3 , premix the dry powder for 45min-60min, then add water and acid for wet mixing; add 0.3% high-purity humic acid and 1.5% inorganic expansion agent ultrafine barium sulfate to the negative lead paste in the existing negative lead paste, grid After the paste is applied, the electrode plate 3 is made.

[0016] 2. The solidified and dried positive and negative plates are grouped according to 6 positive and 7 negative, and a total of 28 2V200Ah batteries are assembled. The pole group is pre-pressed on a special baler, the assembly pressure is set to 80kPa, and 2 cable ties 4 a...

Embodiment 2

[0023] Example 2: Take the most common type 2V500Ah battery as an example:

[0024] The silver content of the positive grid is 0.05% of the total weight of the alloy, and the Y in the positive lead paste formula 2 O 3 The ratio is 1.5%, and the rest of the process refers to Example 1, and small batch trial production is carried out, and a total of 150 2V500Ah batteries are assembled. Compared with ordinary batteries of the same type, the capacity and consistency of the batteries are better than those of ordinary batteries. The high temperature float charge at 60°C has been carried out 13 times, the capacity has dropped by 4.6%, and the number of large cycles is expected to reach about 20; Second, the product testing situation is basically the same as that of the high-temperature battery in Example 1, and the high-temperature performance of the product is also excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com