Inorganic nanoparticle in-situ modified polybenzimidazole proton exchange membrane and preparation method thereof

A polybenzimidazole, proton exchange technology, applied in the direction of final product manufacturing, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of decreased proton conductivity, corrosion of metal parts of fuel cells, low proton conductivity, etc. , to achieve the effect of strong water absorption and water retention capacity and good proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

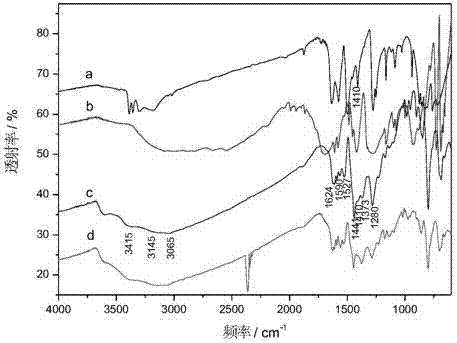

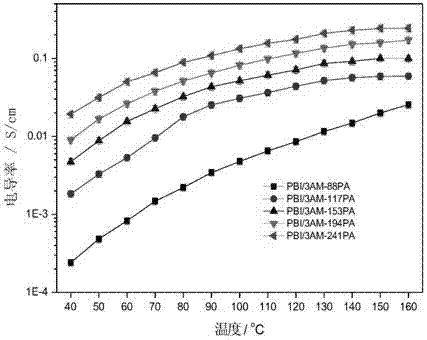

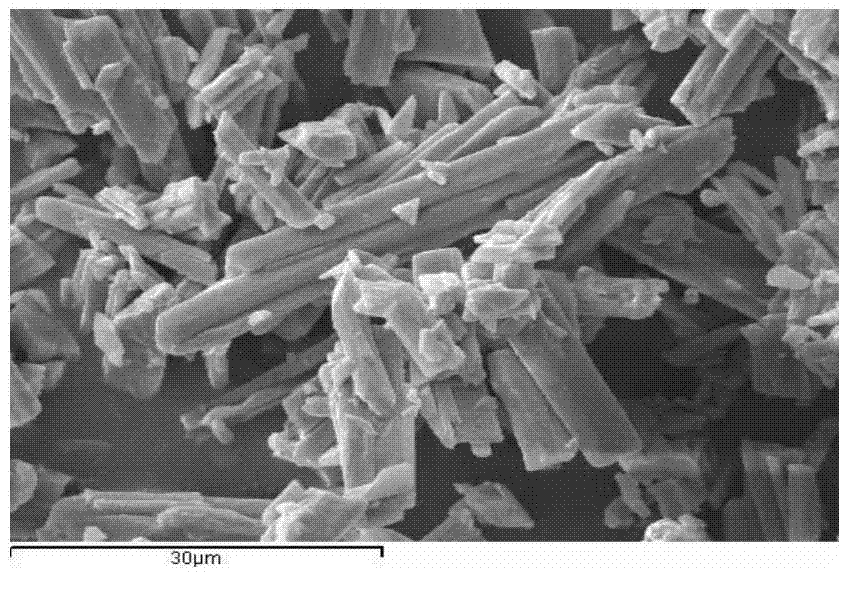

[0053] The invention provides an electrolyte membrane composition for a proton exchange membrane fuel cell and a preparation method thereof. The electrolyte membrane composition includes in-situ polymerized polybenzimidazole polymers, polysemisiloxane nanoparticles with a three-dimensional cage structure with eight amino groups, and doped phosphoric acid. In the composition, the adsorbed phosphoric acid exists in the form of ionic chemical bonds, so that in the proton exchange membrane, protons can be transferred through a large amount of phosphoric acid without reducing the conductivity due to the loss of phosphoric acid. On the other hand, the introduced The siloxane has strong water absorption and water retention capacity, which improves the performance of the proton exchange membrane and prolongs the service life.

[0054] The polysesquioxane nanoparticles with three-dimensional cage structure with eight amino groups have a chemical formula as follows:

[0055]

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com