Pholiota nameko mushroom block, mushroom block production process and special device of production of mushroom block

A production process, the technology of slide mushroom, is applied in the field of edible fungus production, which can solve the problems of high pollution rate of strain production, many manual operation procedures, and high cost of bacterial curtain production, so as to reduce artificial operation pollution, low production cost, and prevent The effect of immersion of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

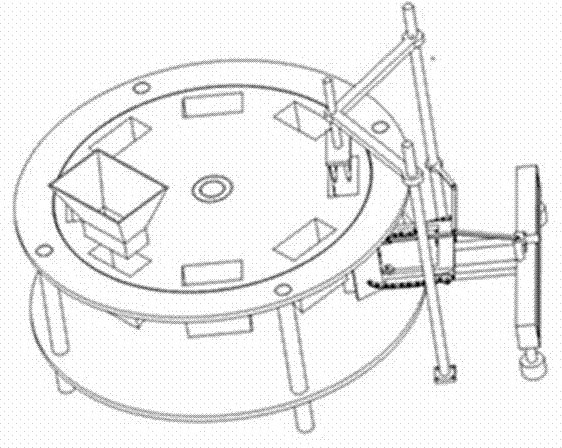

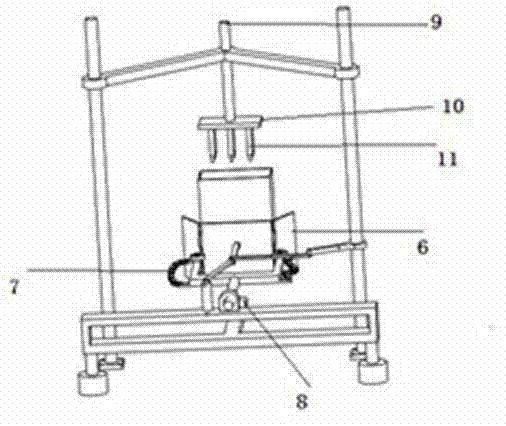

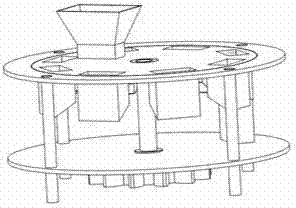

Image

Examples

Embodiment 1

[0039] Preparation of cultivation materials: The purchased cultivation materials are inspected and accepted by professional technicians and put into storage for use. Pour 75kg of sawdust, 23kg of bran and 2kg of slaked lime into the mixing pot through a dumper and stir for 40 minutes. After stirring evenly The mixture is conveyed to the feed hopper of the briquetting machine or the feed hopper of the automatic bottling machine used for strain cultivation through the conveyor belt;

[0040] Preparation of strains: Propagate the mother species in a test tube, cultivate in an environment of 15°C until the mycelia cover the slope; then make the original species: mix and stir the raw materials of the cultivation materials in proportion, and fill the cultivation materials with an automatic bottler In the plastic strain bottle with air-permeable film, transfer the parent species to the plastic strain bottle with air-permeable film in the 10,000-level purification area to cultivate m...

Embodiment 2

[0045] Preparation of planting materials: The purchased planting materials are inspected and accepted by professional technicians and put into storage for use. Pour 77kg of sawdust, 22kg of bran and 1kg of slaked lime into the mixing pot through a dumper and stir for 30 minutes. After stirring evenly Transfer the mixture to the hopper of the briquetting machine or the hopper of the automatic bottling machine used for strain cultivation through the conveyor belt;

[0046]Preparation of strains: Propagate the mother species in a test tube, cultivate in an environment of 25°C until the mycelia cover the slope; then make the original species: mix and stir the raw materials of the cultivation materials in proportion, and fill the cultivation materials with an automatic bottler In the plastic strain bottle with air-permeable film, transfer the parent species to the plastic strain bottle with air-permeable film in the 10,000-level purification area to cultivate mycelia for 40 days, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com