Degradable vascular stent, and manufacturing method thereof

A technology for vascular stents and degrading polymers, used in stents, medical science, surgery, etc., can solve the problems of poor mechanical properties of polymer networks, insufficiently compact stents, unstable stent performance, etc., to reduce mechanical relaxation behavior, reduce The effect of retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0046] The degradable vascular stent according to the present invention is formed by laser cutting a polymer tube with a three-dimensional cross-linked network structure. In the following, two examples will be combined to illustrate the process of preparing polymer pipes with a three-dimensional cross-linked network structure.

example 1

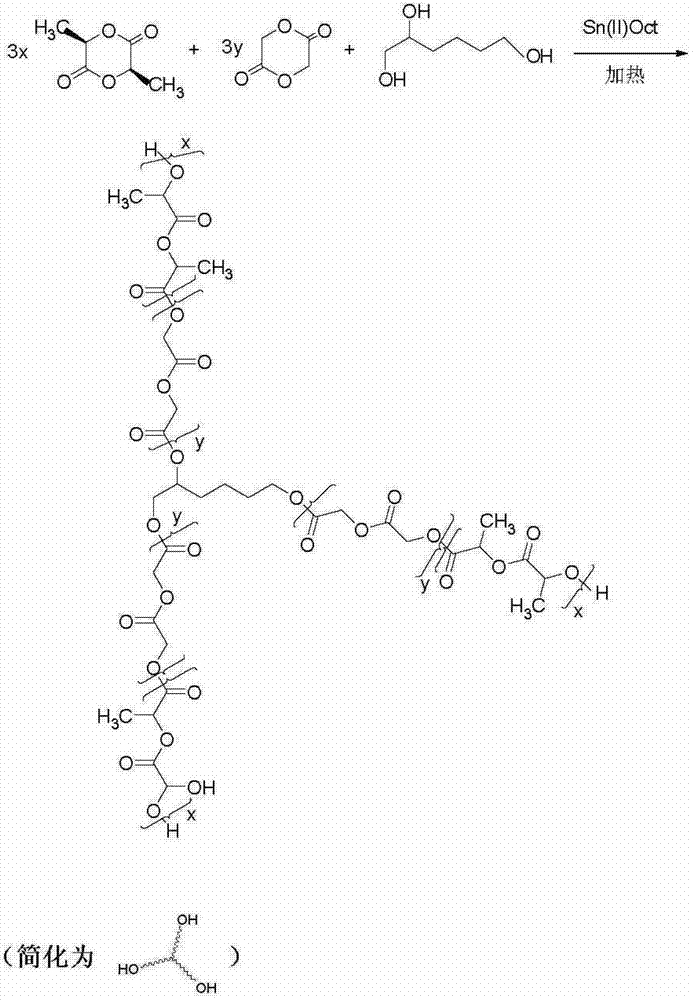

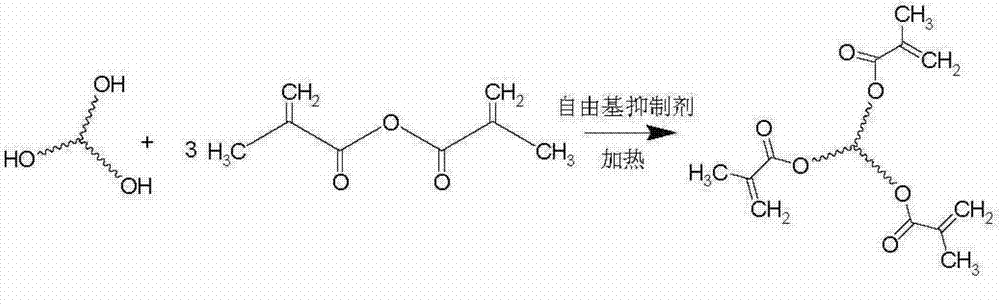

[0048] Synthesis of Star Polylactic Acid Copolymer Prepolymer and Introduction of Crosslinkable Groups

[0049] Referring to Figure 1(a), a 3-liter glass reactor was vacuum-dried at 80°C for 1 hour before polymerization, and 2100 g of L-lactide, 370 g of glycolide and 22 g (0.16 mol) of 1,2,6- Hexatriol was added into the reaction kettle, and after repeated vacuum and argon gas deoxygenation processes, stannous octoate was added, and the reaction was carried out at 145°C. When the number-average molecular weight of the star-shaped polylactic acid copolymer prepolymer meets the requirements of the experimental design, add 114 grams (0.741 mol) of methacrylic anhydride and 0.75 grams of free radical inhibitors such as p-hydroxyanisole to form cross-linked Star polymers with linked reactions (see Fig. 1(b)). After the reaction, the temperature was lowered to 60°C, 5 liters of ethyl acetate was added to the reactor to dissolve the prepolymer, and then slowly poured into the mixed...

example 2

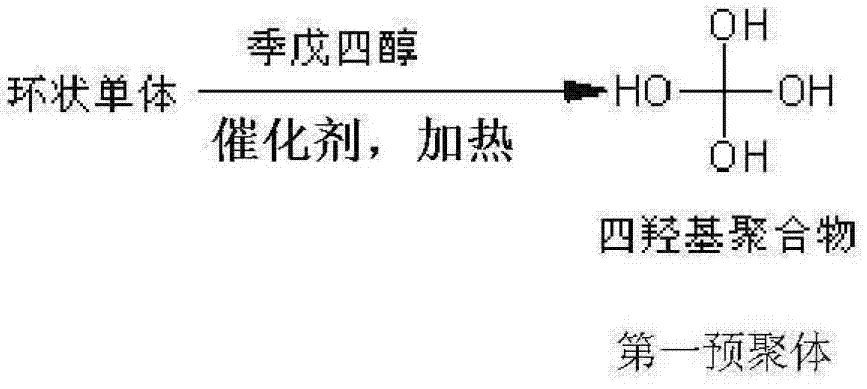

[0063] As shown in Figure 2(a), firstly, cyclic monomers or cyclic comonomers, such as L-lactide and ε-caprolactone (L-LA / ε-CL molar ratio of 95 / 5) Synthesize star-shaped degradable polymer copolymer as the first prepolymer.

[0064]The second step is to synthesize the cross-linking agent, see Figure 2(b) for details. Use the same method as the first step to synthesize the second prepolymer of star-shaped copolymers with hydroxyl groups, such as L-lactide and ε-caprolactone (L-LA / ε-CL molar ratio is 95 / 5 ), but different from the first prepolymer prepared in the first step, the number average molecular weight of the second prepolymer is controlled between 500 and 100,000. Then by polycondensation, in the molecules of the second prepolymer (here including 2, 3 or 4 arm linear or star polymer, but preferably with 3 or 4 arm star polymer) isocyanate is introduced, and the remaining isocyanate is removed by polymer precipitation washing to ensure that there is no isocyanate resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com