TiO2 microsphere and preparation method therefor

A technology of microspheres and temperature control, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of difficult preparation of 1-10mm microspheres, and achieve less operation steps, simple operation and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

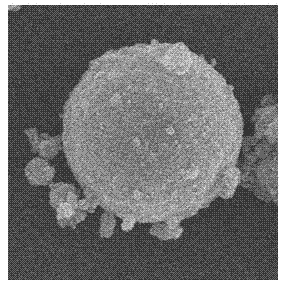

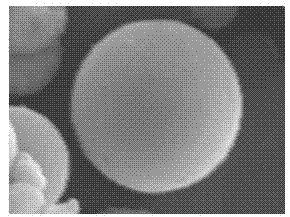

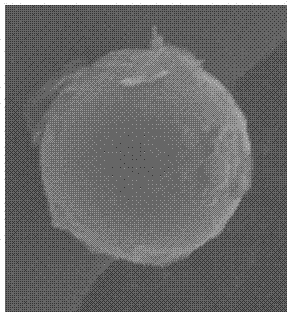

Image

Examples

Embodiment 1

[0033] A kind of TiO 2 Microspheres, the size of the microspheres is between 4-5mm.

[0034] One of the above TiO 2 The preparation method of microsphere specifically comprises the following steps:

[0035] (1) At room temperature, add 34g tetrabutyl titanate (100mmol) and 8.1g octadecylamine (30mmol) into 500mL ethylene glycol, control the concentration of tetrabutyl titanate to 0.2mol / L, octadecylamine Amine concentration is 0.06mol / L to make solution A;

[0036] (2) At room temperature, mix 200mL of water (11mol) and 500mL of ethanol, and control the concentration of water to 16mol / L to obtain solution B;

[0037] (3) Calculated according to the volume ratio, that is, the ratio of solution B: solution A is 7:5, first add 7mL solution B to a 50mL autoclave, and then put the container containing 5mL solution A into the autoclave In the kettle, the temperature was controlled to be 180° C. for 12 hours to obtain a reaction solution;

[0038] (4) Cool the autoclave to room ...

Embodiment 2

[0042] A kind of TiO 2 Microspheres, the size of the microspheres is between 2-5mm.

[0043] One of the above TiO 2 The preparation method of microsphere specifically comprises the following steps:

[0044] (1) At room temperature, add 34g tetrabutyl titanate (100mmol) and 27g octadecylamine (100mmol) to 500mL ethylene glycol, control the concentration of tetrabutyl titanate to 0.2mol / L, octadecylamine Concentration is 0.2 mol / L to make solution A;

[0045] (2) At room temperature, mix 200mL of water (11mol) and 500ml of ethanol, and control the concentration of water to 16mol / L to obtain solution B;

[0046] (3) Calculated according to the volume ratio, that is, the ratio of solution B: solution A is 7:5, first add 7mL solution B to a 50ml autoclave, and then put the container containing 5mL solution A into the autoclave In the kettle, the temperature was controlled to be 180° C. for 12 hours to obtain a reaction solution;

[0047] (4) Cool the autoclave to room temperat...

Embodiment 3

[0051] A kind of TiO 2 Microspheres, the size of the microspheres is between 4-7mm.

[0052] One of the above TiO 2 The preparation method of microsphere specifically comprises the following steps:

[0053] (1) At room temperature, add 34g of tetrabutyl titanate (100mmol) tetrabutyl titanate and 54g of octadecylamine (200mmol) into 500mL of ethylene glycol, and control the concentration of tetrabutyl titanate to 0.2mol / L, stearylamine concentration are 0.4mol / L to make solution A;

[0054] (2) At room temperature, mix 200mL of water (11mol) and 500mL of ethanol, and control the concentration of water to 16mol / L to obtain solution B;

[0055] (3) Calculated according to the volume ratio, that is, the ratio of solution B: solution A is 7:5, first add 7mL solution B to a 50mL autoclave, and then put the container containing 5mL solution A into the autoclave In the kettle, the temperature was controlled to be 180° C. for 12 hours to obtain a reaction solution;

[0056] (4) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com